Biochar-based slow release fertilizer and preparation method thereof

A biochar based fertilizer and material technology, applied in nitrogen fertilizer, potash fertilizer, phosphate fertilizer and other directions, can solve the problems of insignificant effect, no specific effect of improving fertilizer utilization rate, high temperature of carbonization of CN106748196A, and achieve good pore structure and slow release performance. , Improve the effect of increasing production and reducing the effect of high temperature carbonization exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

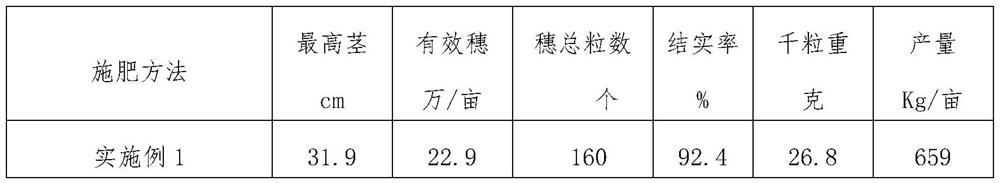

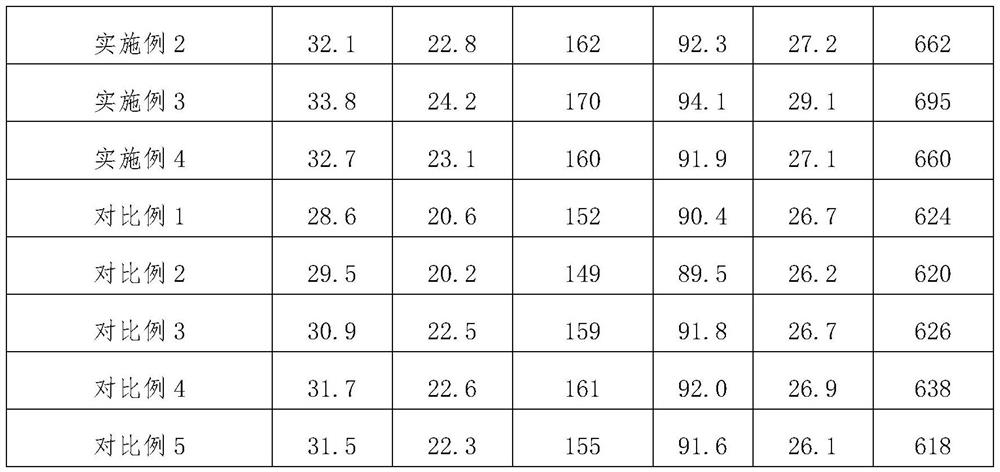

Examples

preparation example Construction

[0028] A preparation method of biochar-based fertilizer, the specific preparation steps are as follows: (1) grind crop stalks into powder with a special grinder, and take straw micropowder with a particle diameter not exceeding 5 mm for use; (2) use the stalks obtained in step (1) The straw micropowder and phosphoric acid are added into the kneader in a certain proportion, and the effectively soaked straw micropowder inside is obtained by setting the kneader blade speed and kneading temperature; the weight of the straw micropowder is 100kg, and the weight of the phosphoric acid solution is 5kg; (3) The soaked straw micropowder obtained in step (2) and urea, potassium sulfate, superphosphate, and potassium humate (commercially available raw materials can be used, and can also be obtained by reacting lignite with potassium hydroxide, which is a conventional acquisition method in the art) Add in the high-speed mixer according to a certain ratio, and mix at a high speed for a perio...

Embodiment 2

[0031] A preparation method of biochar-based fertilizer, the specific preparation steps are as follows: (1) grind crop stalks into powder with a special grinder, and take straw micropowder with a particle diameter not exceeding 5 mm for use; (2) use the stalks obtained in step (1) Add straw micropowder and phosphoric acid into the kneader according to a certain ratio, set the kneader blade speed and kneading temperature, and obtain straw micropowder effectively soaked inside; wherein the weight of straw micropowder is 100kg, and the weight of phosphoric acid solution is 5kg; (3) the step (2) The resulting soaked straw micropowder, urea, potassium sulfate, superphosphate, and potassium humate are added to a high-speed mixer in a certain proportion, mixed at a high speed for a period of time, and a uniformly dispersed composite material is obtained; the weights of the four substances are respectively Be: 100kg, 30kg, 20kg, 5kg, 15kg; (4) the composite material obtained in step (3...

Embodiment 3

[0033] A preparation method of biochar-based fertilizer, the specific preparation steps are as follows: (1) grind crop stalks into powder with a special grinder, and take straw micropowder with a particle diameter not exceeding 5 mm for use; (2) use the stalks obtained in step (1) Add straw micropowder and phosphoric acid into the kneader according to a certain ratio, set the kneader blade speed and kneading temperature, and obtain straw micropowder effectively soaked inside; wherein the weight of straw micropowder is 100kg, and the weight of phosphoric acid solution is 5kg; (3) the step (2) The resulting soaked straw micropowder, urea, potassium sulfate, superphosphate, and potassium humate are added to a high-speed mixer in a certain proportion, mixed at a high speed for a period of time, and a uniformly dispersed composite material is obtained; the weights of the four substances are respectively Be: 100kg, 20kg, 15kg, 5kg, 10kg; (4) the composite material obtained in step (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com