Transport cart for aluminum ingot production

A technology for transport vehicles and aluminum ingots, which is applied in transportation and packaging, trolleys, motor vehicles, etc., and can solve problems such as single function, inflexible adjustment, and inability to fix aluminum ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

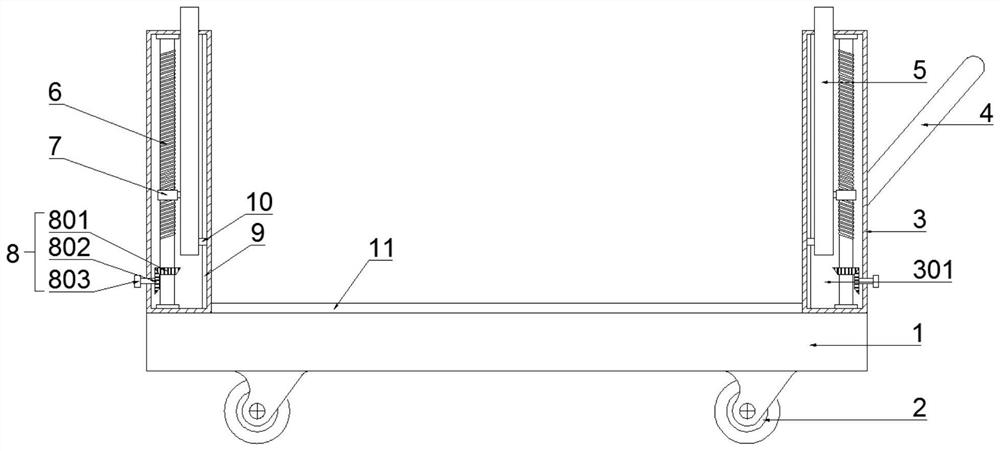

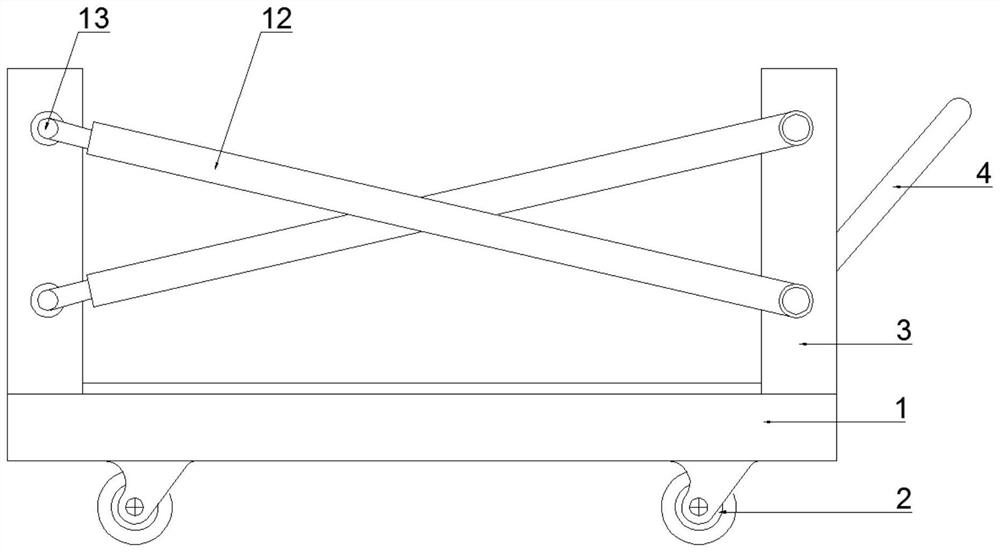

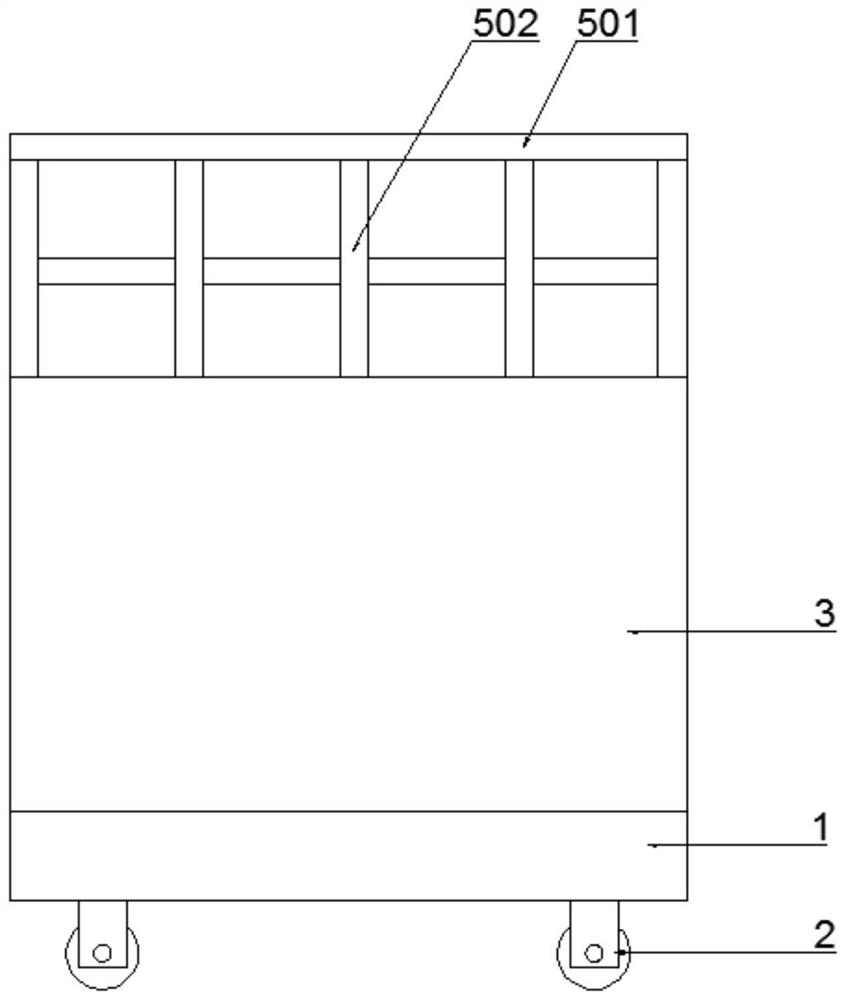

[0024] refer to figure 1 , see figure 1 , 2 and 3, the present embodiment provides a transportation vehicle for aluminum ingot production, which includes a load-bearing base plate 1, and two fixing plates 3 are arranged oppositely on the load-bearing base plate 1, wherein one side of the fixing plate 3 is connected to an elastic band 12, and the other Fixed plate 3 sides are provided with fixed buckle 13 correspondingly; Described fixed plate 3 is provided with cavity 301, and described cavity 301 is provided with lift stop frame 5, and described lift block frame 5 is slidably connected with the inner wall of cavity 301, so The cavity 301 is also rotatably connected with a screw rod 6, the screw rod 6 is screwed with a moving block 7, the lifting block frame 5 is connected with the moving block 7, and the screw rod 6 is also connected with an adjustment device for driving the screw rod 6 to rotate. Component 8.

[0025] When in use, the aluminum ingots are stacked on the lo...

Embodiment 2

[0027] This embodiment is further preferred on the basis of Embodiment 1, refer to figure 1 and 2 , the upper surface of the bearing base 1 is provided with a non-slip pad 11 . The setting of the anti-skid pad 11 can play an anti-skid effect, prevent the aluminum ingot from sliding, improve the stability of the aluminum ingot stack, and thus improve the stability and safety of transportation.

Embodiment 3

[0029] This embodiment is further preferred on the basis of Embodiment 1, refer to figure 1 and 2 , the side of the lifting block 5 away from the screw rod 6 is provided with a slide block 10, and the inner wall of the cavity 301 is provided with a slide rail 9 cooperating with the slide block 10; the setting of the slide block 10 and the slide rail 9 can improve the lift The stability that block frame 5 rises and falls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com