Auxiliary device for construction barricade and method of constructing barricade of auxiliary device

An auxiliary device and retaining wall technology, which is applied to safety devices, earth-moving drilling, mining equipment, etc., can solve the problems of increasing the construction cost of retaining walls, being easily damaged, and polluting the underground environment, so as to improve the reuse rate and avoid shaking. Collapse, the effect of increasing the disassembly rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

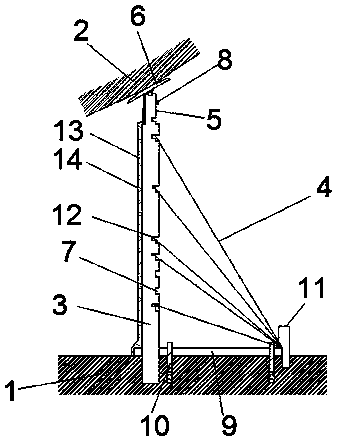

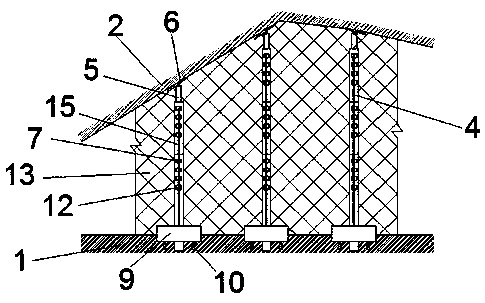

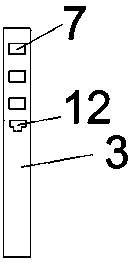

Embodiment 1

[0039] see Figure 1-3 , an auxiliary device for constructing a retaining wall, comprising a base plate 1 and a roof rock 2, a column 3 is arranged between the base plate 1 and the roof rock 2, and the bottom end of the column 3 extends into the base plate 1 excavated in advance In the fixing hole, and between it and the bottom plate 1, there are several supports arranged obliquely. The supports are steel bars 4. Connecting rod 15, the connecting rod 15 at the head end is detachably connected with the column 3, the connecting rod 15 at the head end refers to the connecting rod 15 at the bottom, and the connecting rod 15 at the tail end is detachably connected with the supporting cap , the connecting rod 15 at the tail end refers to the connecting rod 15 located at the top, the side of the column 3 away from the support is connected with a double-layer steel wire mesh 13, and a geotextile 14 is laid outside the steel wire mesh.

[0040] see Figure 4The detachable connection ...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that the connection between the connecting rods 15, between the connecting rods 15 and the column 3, and the detachable connection between the connecting rods 15 and the supporting cap is different, and other structures are the same as those of Embodiment 1 same.

[0051] The top inwall of column 3 is provided with internal thread, and the outer wall of the second connecting rod 17 is provided with the external thread that matches with internal thread, and the inwall of the first connecting rod 16 is provided with internal thread, and the support bar 5 outer wall of supporting top solid cap is provided with. There are external threads, and the threaded connection is realized through the cooperation of the internal threads and the external threads, and the adjacent connecting rod 15, the connecting rod 15 and the column 3, and the connecting rod 15 are connected with the supporting cap to realize a detachable conn...

Embodiment 3

[0053] The difference between this embodiment and Embodiment 1 is that flange connections are used between the connecting rods 15, between the connecting rods 15 and the column 3, and between the connecting rods 15 and the supported top caps. Other structures are the same as those in the embodiment. 1 is the same.

[0054] Changes in the above technical features can be understood and implemented by those skilled in the art through written descriptions, so no additional drawings are provided for illustration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com