A delivery vehicle and a delivery system

A delivery vehicle and frame technology, which is applied to motor vehicles, goods transport vehicles, and vehicles used for freight transportation, etc., can solve the problems of easy slipping, large area occupied by forklifts, and large pollution caused by distribution methods, so as to save storage space, The effect of flexible distribution and expansion of storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

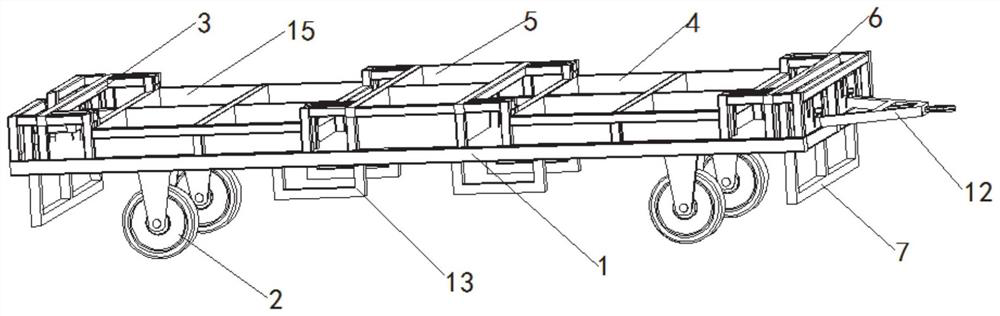

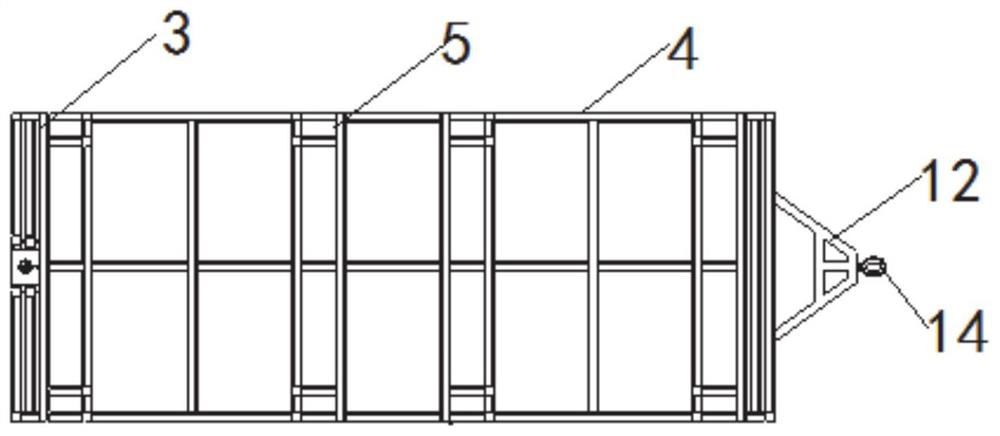

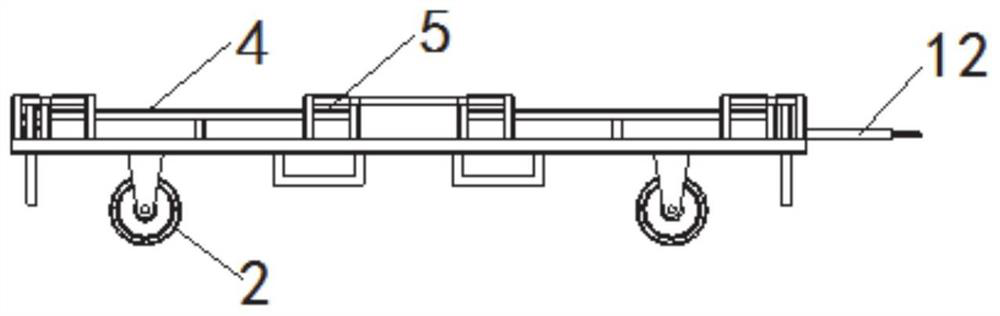

[0054] In a typical embodiment of the present invention, refer to Figure 1-Figure 3 As shown, a distribution vehicle includes a vehicle frame 1, at least one end of the vehicle frame 1 is provided with a traction structure 12, the vehicle frame 1 has wheels, and a positioning structure 4 is provided on one side of the vehicle frame relative to the wheels, and the positioning structure 4 is used for zero alignment. Components such as components or the first container 10 for storing components are limited, and at least one end of the vehicle frame is provided with a stacking structure 3, so that when the distribution vehicle is stacked up and down, two adjacent stacking structures 3 cooperate up and down, and when the distribution vehicle is stacked, The positioning structure of the lower delivery vehicle can accommodate the wheels of the upper delivery vehicle adjacent to it.

[0055] Further, the stacking structure 3 includes a first part 6 arranged on one side of the vehicle...

Embodiment 2

[0074] In this embodiment, on the basis of Embodiment 1, a fork hole is provided on the side of the vehicle frame relative to the positioning structure. The fork hole 13 is used to accommodate the fork arm of the forklift. There are 4 fork holes, two of which are arranged on the same straight line. The other two are set on another straight line. During long-distance delivery, the entire delivery vehicle needs to be loaded and unloaded with a forklift, and the universal wheels are locked during transportation.

[0075] In addition, in some examples, considering that the delivery vehicles need to be stacked up and down for storage, when the delivery vehicle is placed horizontally, the lower end surface of the convex part is set beyond the lower end surface of the fork hole, which will not prevent the convex part from snapping into the first fork hole. in the recess of the part.

Embodiment 3

[0077] In this embodiment, on the basis of Embodiment 1, the materials of the first container, the second container and the third container are limited, for example, the first container, the second container and the third container are all plastic parts, so as to reduce the respective the quality of.

[0078] Of course, in some other examples, the materials of the three can also be other choices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com