Scratch-resistant ACS/PBAT compound and preparation method and application thereof

A composite, scratch-resistant technology, applied in the field of engineering plastics, can solve problems such as poor scratch resistance, and achieve the effects of excellent scratch resistance, good gloss, and small color deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20

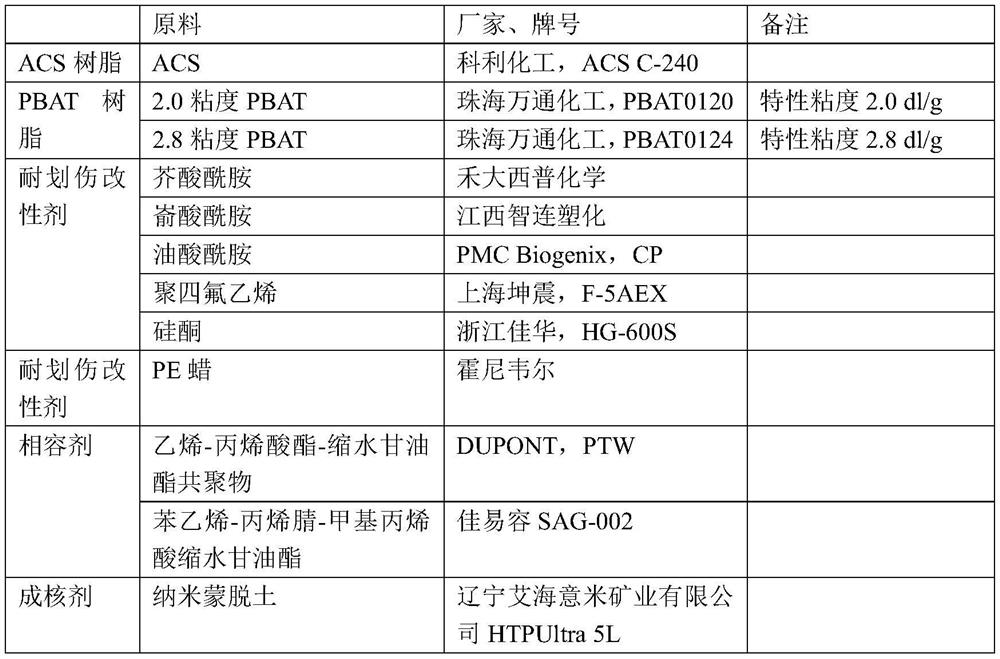

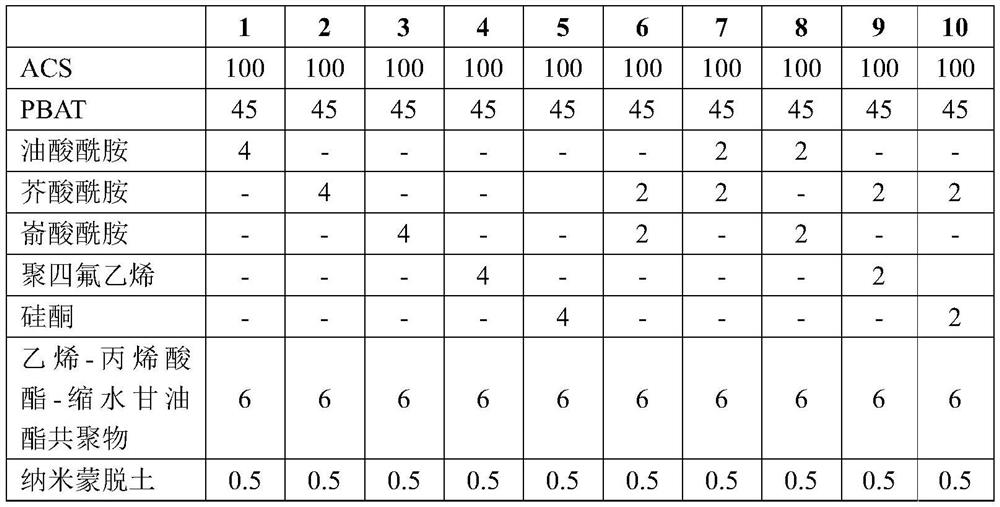

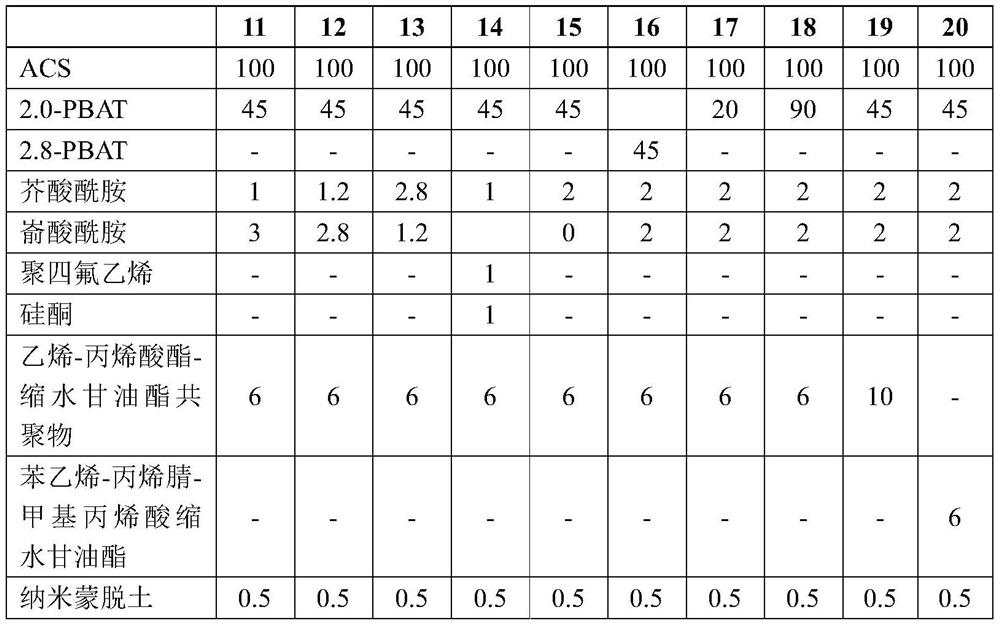

[0054] The content of each component in the ACS / PBAT complexes of Examples 1-20 is shown in Table 1.

[0055] Its preparation method is:

[0056] S1. According to Table 1, dry the PBAT resin at 90°C until the moisture content is ≤0.2%, mix it with the scratch resistance modifier, add it into a twin-screw extruder, melt blend, extrude and granulate to obtain masterbatch ;

[0057] S2. After mixing the masterbatch, ACS resin, nucleating agent, compatibilizer and additives, add them to a twin-screw extruder, melt blend, extrude and granulate to obtain the scratch-resistant ACS / PBAT compound .

[0058]Among them, the temperature of the first to second zones of the twin-screw extruder is 120°C to 170°C, the temperature of the third to fifth zones is 160°C to 180°C, the temperature of the fifth to tenth zones is 170°C to 190°C, and the screw speed is 350rpm to 450rpm;

[0059] The screw combination of the twin-screw extruder is:

[0060] The screw combination in the melting sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com