A kind of super-tough pom composition and its preparation method and application

A composition and super tough technology, applied in the field of polymer materials, can solve the problem of low toughness of POM resin, and achieve the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0063] According to the formula in Table 1, add POM resin, polyether block amide elastomer, TPU elastomer and additives into the mixer and mix evenly, then feed into the twin-screw extruder at a feeding rate of 50-200kg / h , where the temperature of each screw barrel from the feeding port of the twin-screw extruder to the machine head is: 150°C-180°C, 170°C-210°C, 170°C-210°C, 170°C-210°C, 170°C-210°C , 170°C-200°C, 170°C-200°C, 170°C-200°C, 170°C-200°C, 170°C-210°C, the speed of the twin-screw extruder is 250~350r / min, and the vacuum degree is -0.1 ~0MPa, after extrusion, cooling and granulation, remember the super-tough POM composition.

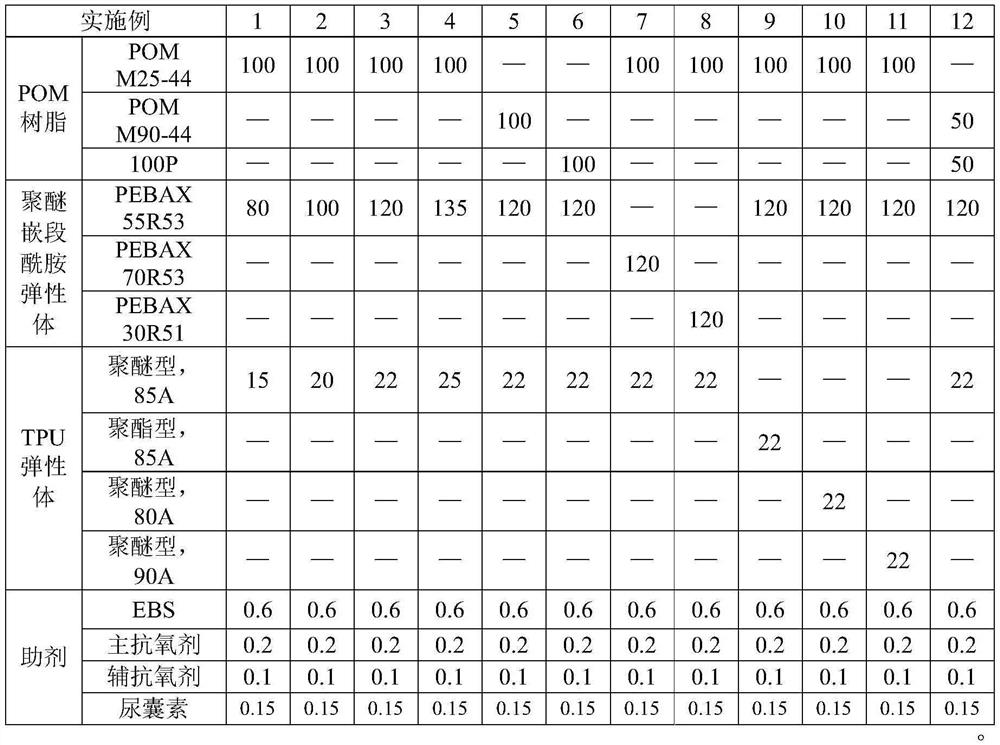

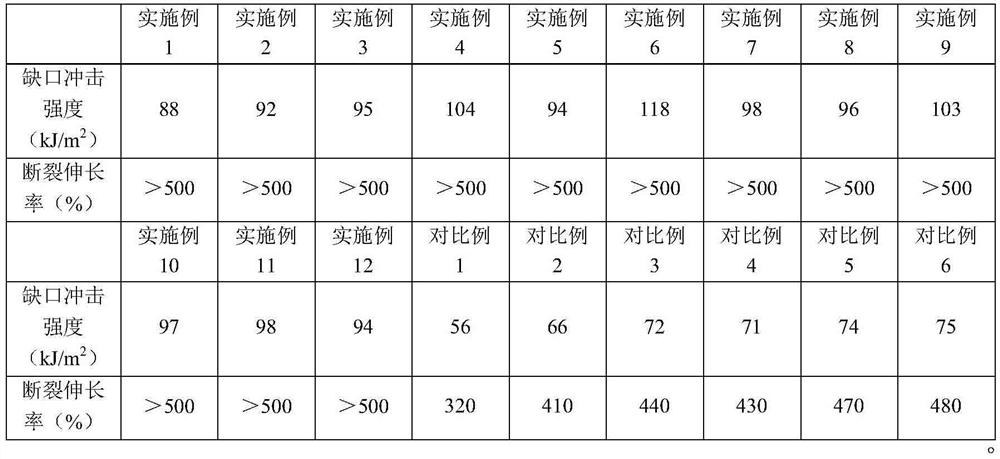

[0064] Each embodiment raw material formula of table 1 (weight part)

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com