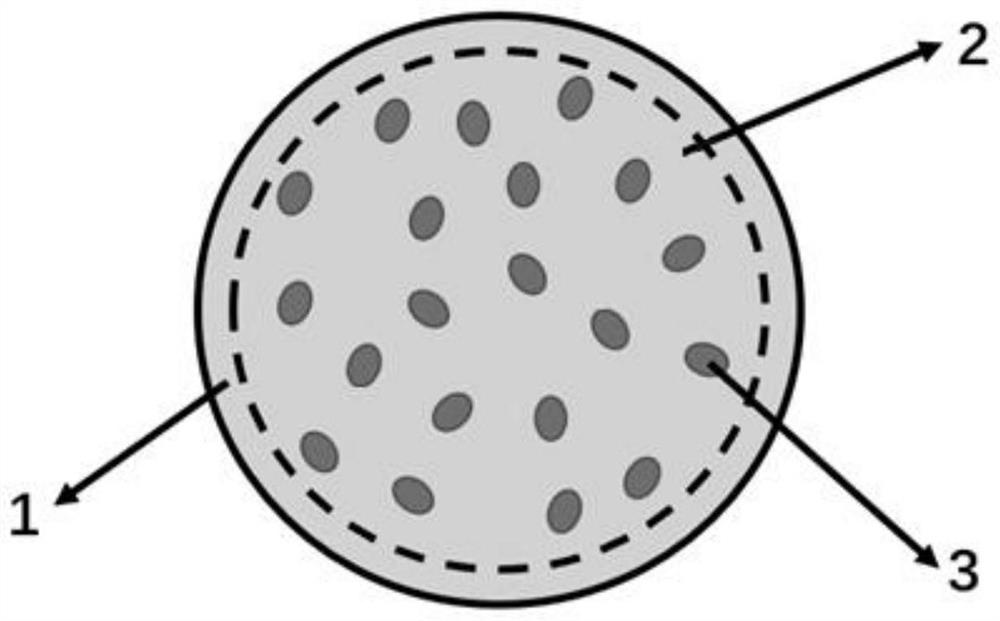

A core-shell structure ceramic composite powder for thermal spraying and its preparation method

A core-shell structure, ceramic composite technology, used in coatings, melt spraying, metal processing equipment, etc., can solve problems such as difficulty in meeting high-temperature thermal protection performance, inability to uniformly disperse two phases, and damage to exothermic coating performance. , to achieve the effect of improving the anti-combustion flow erosion performance, improving the anti-ablation performance, and improving the fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a core-shell structure ceramic-metal composite powder for thermal spraying is carried out as follows:

[0041] (1) Under the premise of protecting the inner core powder, the shell is thinned. Through the volume formula and density calculation of the sphere, it is obtained that in the composite powder of the core-shell structure, the content of the nano-scale ceramic shell powder is 5~25ωt%. The content of the second metal phase in the medium is 5~50ωt%;

[0042] (2) According to the content of the second metal phase in the inner core of 30ωt%, YSZ powder with a particle size of 1~3μm and Cu powder are mixed and added to the PVA solution with a concentration of 0.5ωt%, so that the entire powder The solid content is 60ωt%, and the ball milling is performed at a speed of 350rpm for 2 hours to form a uniform slurry;

[0043] (3) Spray and granulate the ball-milled slurry, the inlet temperature is 330°C, the outlet temperature is 120°C, the rotation s...

Embodiment 2

[0050] A method for preparing a core-shell structure ceramic-metal composite powder for thermal spraying is carried out as follows:

[0051] (1) Under the premise of protecting the inner core powder, the shell is thinned. Through the volume formula and density calculation of the sphere, it is obtained that in the composite powder of the core-shell structure, the content of the nano-scale ceramic shell powder is 5~25ωt%. The content of the second metal phase in the medium is 5~50ωt%;

[0052] (2) The content of the second metal phase in the inner core is 20ωt%, and Al with a particle size of 1~3μm 2 o 3 Mix the powder and Ni powder into the PVA solution with a concentration of 0.5ωt%, so that the solid content of the whole powder is 45ωt%, and ball mill for 5 hours at a speed of 150rpm to form a uniform slurry;

[0053] (3) Spray granulate the slurry after ball milling, the inlet temperature is 320°C, the outlet temperature is 110°C, the rotation speed of the peristaltic pump...

Embodiment 3

[0060] A method for preparing a core-shell structure ceramic-metal composite powder for thermal spraying is carried out as follows:

[0061] (1) Under the premise of protecting the inner core powder, the shell is thinned. Through the volume formula and density calculation of the sphere, it is obtained that in the composite powder of the core-shell structure, the content of the nano-scale ceramic shell powder is 5~25ωt%. The content of the second metal phase in the medium is 5~50ωt%;

[0062] (2) According to the content of the second metal phase in the inner core of 10ωt%, YSZ powder and NiCrAlY powder with a particle size of 1~3μm are mixed and added to the PVA solution with a concentration of 0.5ωt%, so that the ball is completely powdered The solid content of the mixture is 50ωt%, and the ball milling time is 2 hours at 300rpm to form a uniform slurry;

[0063] (3) Spray granulate the slurry after ball milling, the inlet temperature is 300°C, the outlet temperature is 120°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com