Laser cladding composite coating on magnesium alloy surface assisted by ceramic-based buffer heat insulation layer and preparation method thereof

A composite coating, laser cladding technology, applied in metal material coating process, coating, pressure inorganic powder coating and other directions, can solve the problems of limited selection of magnesium alloy surface modification layer, thermal deformation and other problems, to solve Restricted high melting point alloy, reduced floating, no crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

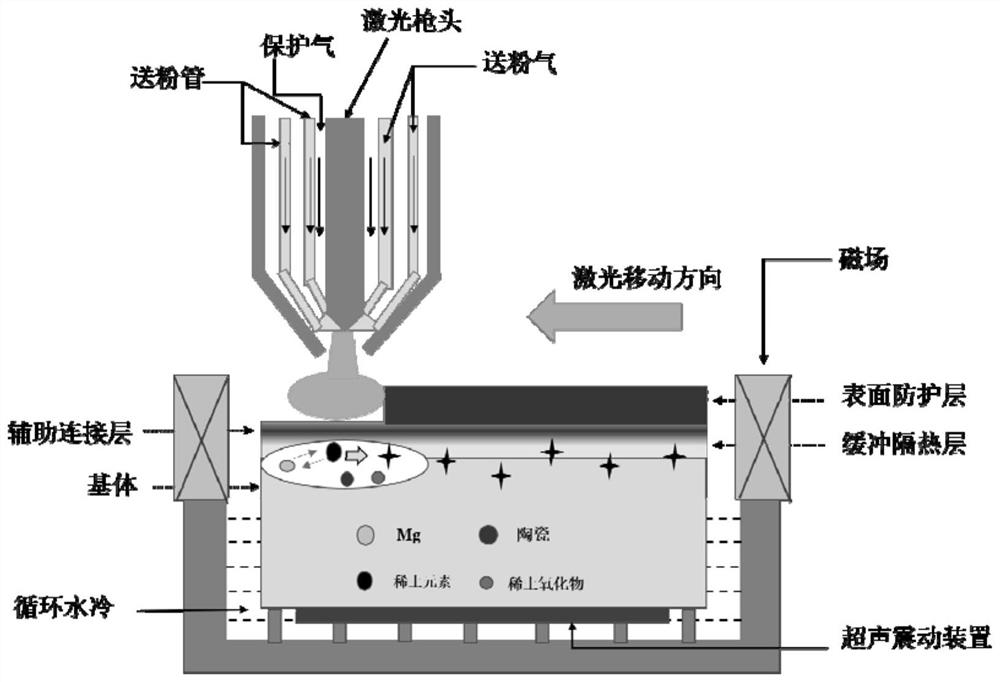

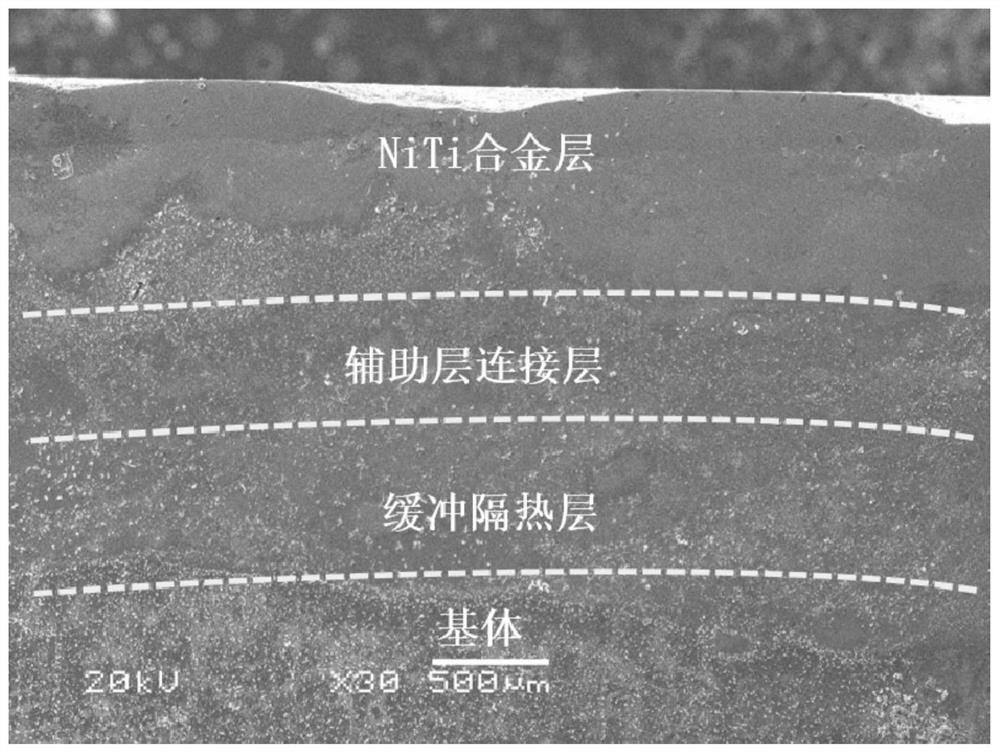

[0027] The invention proposes that before preparing an alloy coating with high hardness and excellent tribological properties on the surface of the magnesium alloy, a ceramic-based buffer heat insulation layer is prepared in advance. After preparing the auxiliary connection layer on the buffer insulation layer, the preparation of the high-performance coating is carried out. And in the laser cladding process, the external field synchronous auxiliary regulation is introduced to solve the problems such as holes and cracks that often occur in the coating preparation process. Thus a high-quality, high-stability composite protective coating on the surface of the magnesium alloy is obtained.

[0028] The present invention provides a ceramic-based buffer heat-insulation layer assisted laser cladding composite coating on the surface of a magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com