Infilled wall structure of steel-concrete structure building and construction method thereof

A steel-concrete structure and infill wall technology, which is applied in building components, building structures, buildings, etc., can solve problems such as affecting normal life and work, affecting emergency evacuation of personnel, and large repair works, so as to prevent excessive deformation. , strong anti-seismic ability, good anti-seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

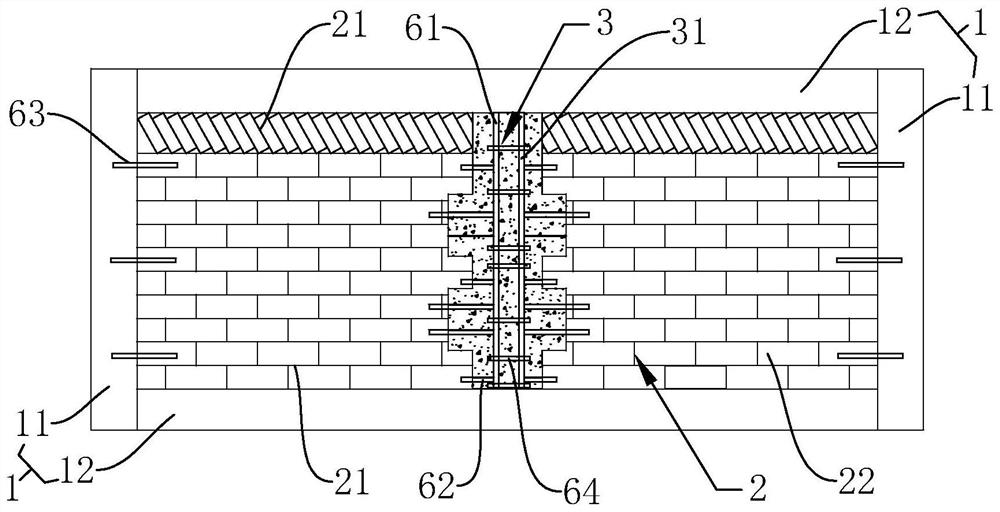

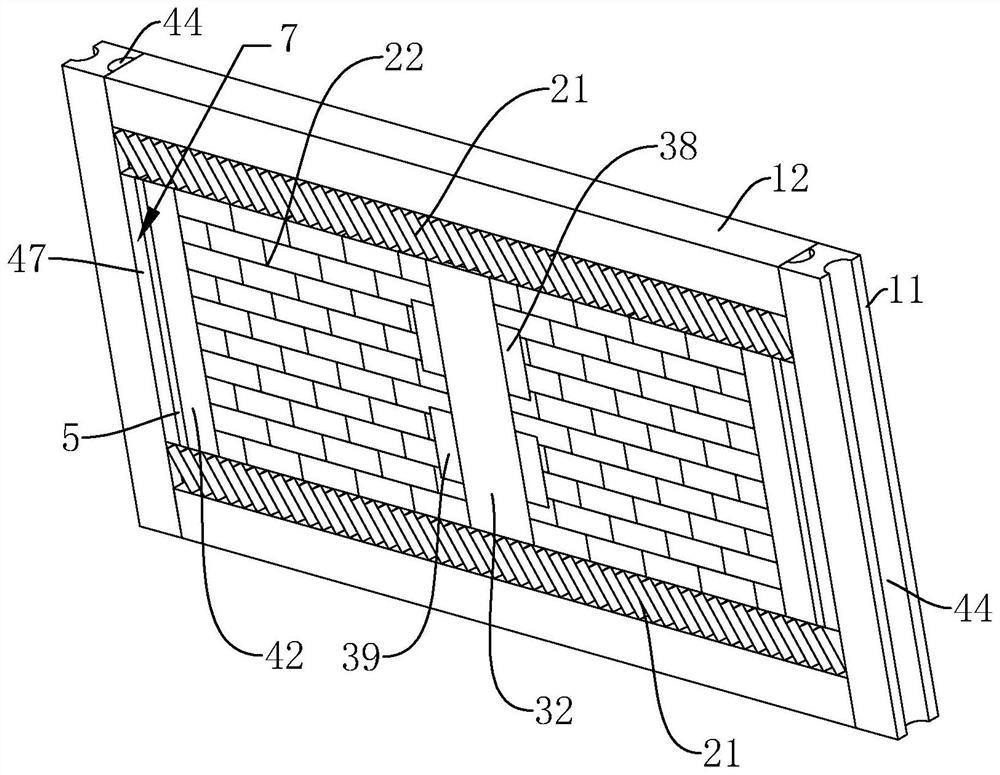

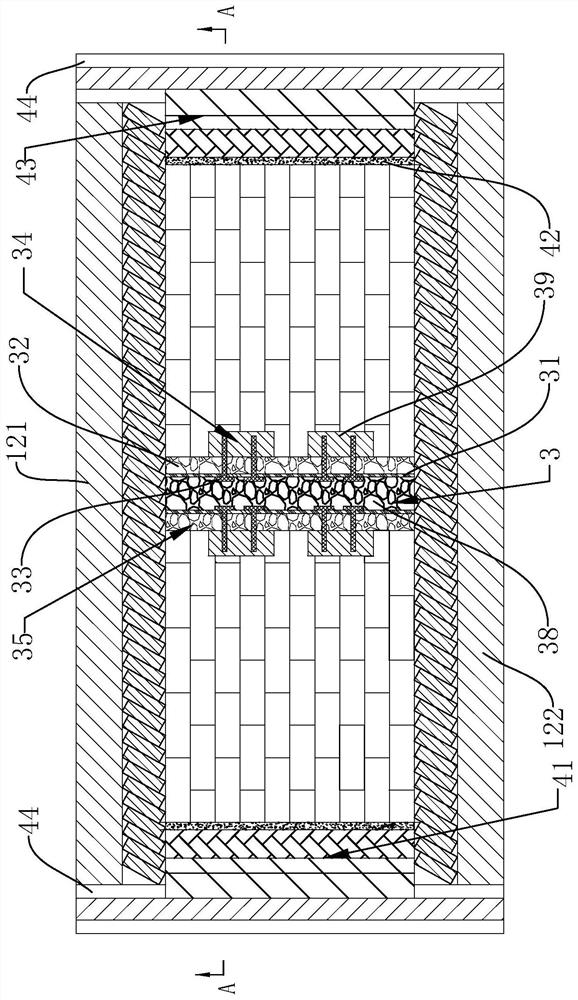

[0046] like figure 1 As shown, the present application provides an infill wall structure for a steel-concrete structure building, including a steel frame 1 composed of two frame columns 11 and two frame beams 12, and the steel frame 1 is lined with inclined walls with vertical bricks arranged obliquely 21. A planar wall 22 arranged horizontally with the vertical bricks. A structural cavity 3 is provided in the middle of the planar wall 22, and a structural column 31 is provided in the structural cavity 3.

[0047] This application is mainly aimed at the structure of the filling wall 2 before improvement, although it can meet the low-strength seismic requirements of small high-rise buildings, but when the above-mentioned steel frame 1 filling wall 2 is the filling wall of a high-rise building (height is more than 85m), or when When the above-mentioned steel f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap