Upper wall end and wallboard connecting integral corner box assembly

A corner box and integral technology is applied in the field of integral corner box assemblies connecting the upper wall end and the wall plate, which can solve the problems of uneven load transmission, large stiffness changes, debonding, etc., so as to avoid sudden changes in stiffness and excessive stiffness changes. The effect of reducing the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

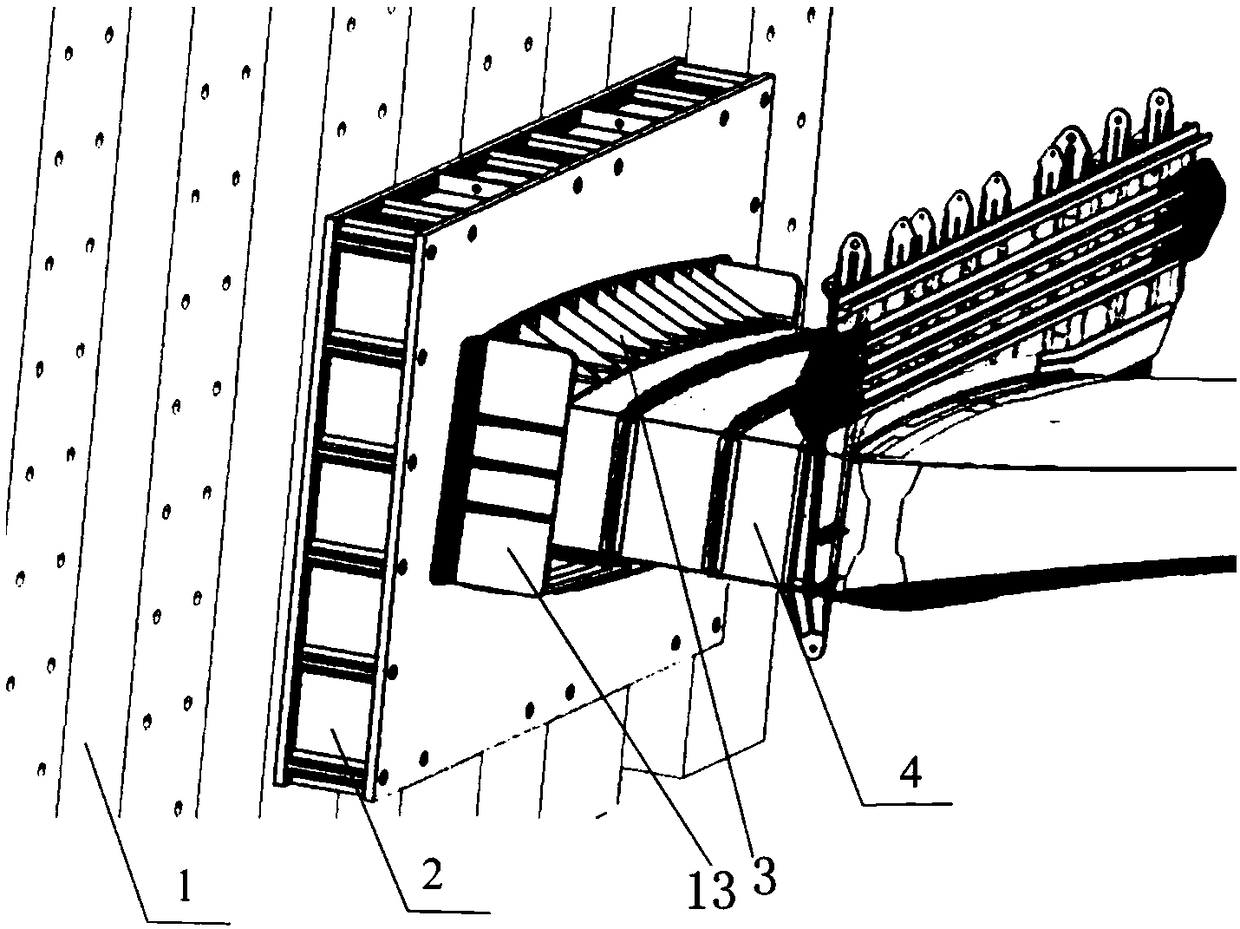

[0047] This embodiment proposes an integral corner box assembly connecting the upper wall end and the wall panel, such as Figure 4 As shown, the connected integral corner box assembly is used for the composite box section test, and the connected integral corner box assembly includes:

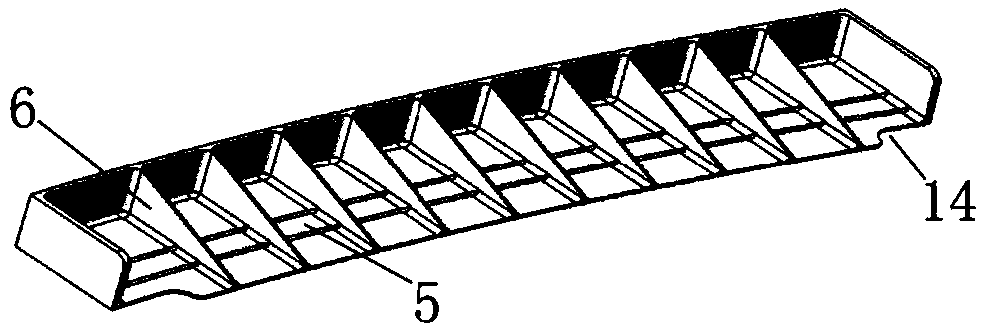

[0048] - an external corner box for securing composite test pieces;

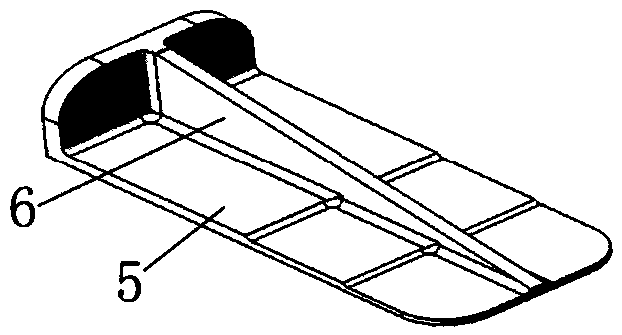

[0049] A number of internal independent small corner boxes for fixing the composite material test piece in cooperation with the external corner box;

[0050] The external corner box is arranged on the outside of the composite material test piece wall panel;

[0051] Several internal independent small corner boxes are symmetrically arranged on the inner side of the composite material test piece wall;

[0052] The external corner box is arranged symmetrically with several of the internal independent small corner boxes.

[0053] The first cut-off area of the external corner box on the composite material test piece is set as a...

Embodiment 2

[0072] This embodiment provides a test method for connecting composite material box segments using the connecting integral corner box assembly described in Embodiment 1.

Embodiment 3

[0074] An integral corner box assembly for connecting the upper wall end and the wall panel provided in this embodiment is basically the same as that in Embodiment 1, except that:

[0075] The material of the external corner box is 45# steel.

[0076] The internal independent small corner box is 45# steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com