Connecting joint of double-wall hollow pier column and bent cap and construction method

A technology for connecting nodes and hollow piers, used in bridge construction, bridges, buildings, etc., to ensure reliability, reliable connection, and smooth stiffness changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

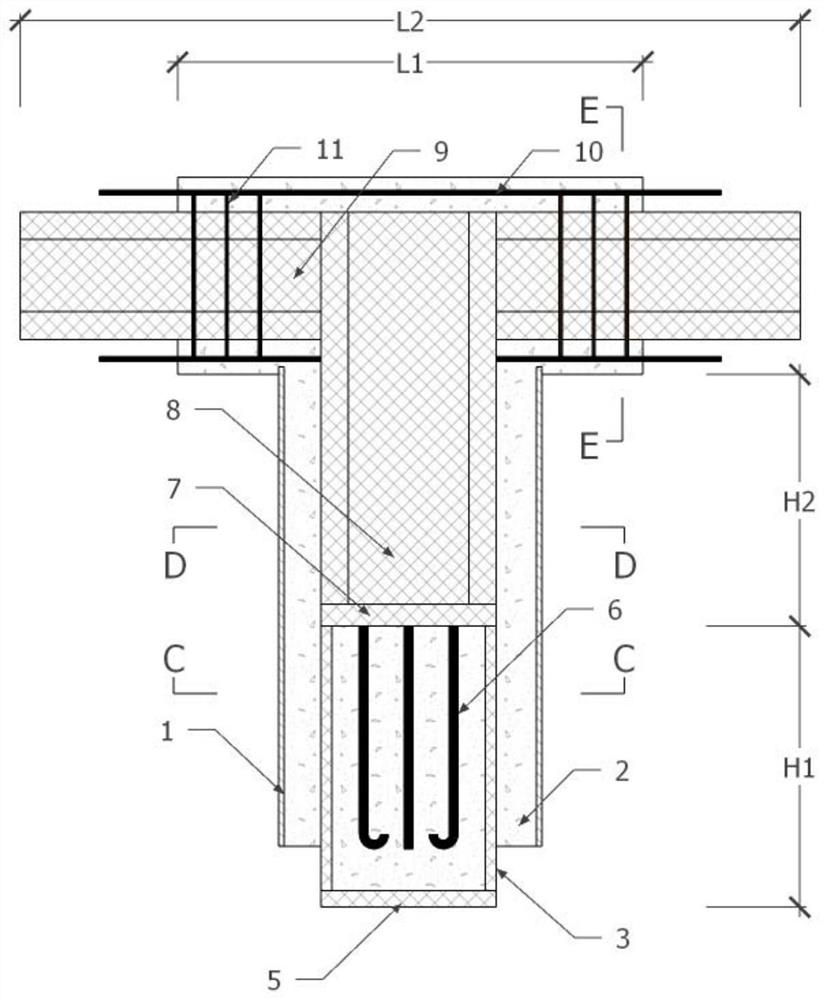

[0047] refer to Figure 4 , this embodiment provides a double-walled hollow pier column and steel reinforced concrete cover beam cast-in-place connection node, the node includes a first transition section, a second transition section and a cover beam transition section.

[0048] In this embodiment, the composite tube-concrete-steel tube double-walled hollow pier successively passes through the composite tube-concrete-steel tube double-tube solid concrete column transition section (the first transition section), and the composite tube-constrained steel reinforced concrete column transition section (the second conversion section) and the steel reinforced concrete cover beam conversion section (cover beam conversion section) are connected with the steel reinforced concrete cover beam. The steel pipe of the double-walled hollow pier column is connected with the steel pipe in the first conversion section through the first steel partition, and then connected with the lower end of th...

Embodiment 2

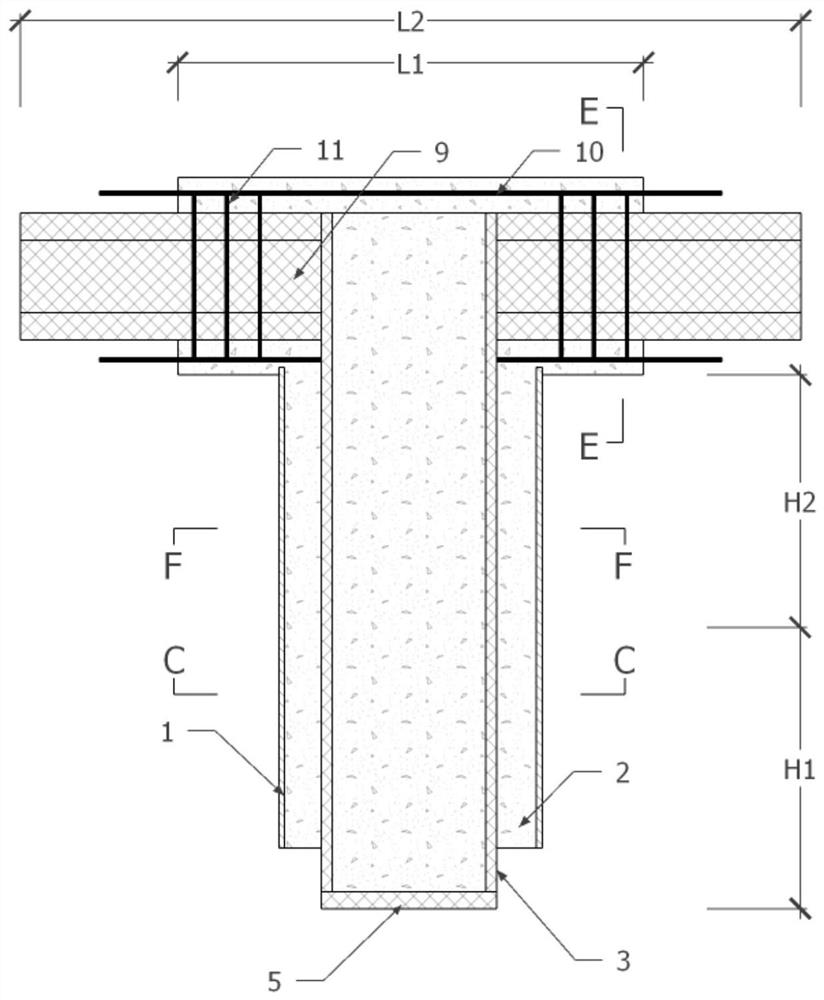

[0062] refer to image 3 , this embodiment provides a double-walled hollow pier column and a reinforced concrete cover beam cast-in-situ connection node, the node includes a first transition section, a second transition section and a cover beam transition section.

[0063] In this embodiment, the composite tube-concrete-steel tube double-walled hollow pier successively passes through the composite tube-concrete-steel tube double-tube solid concrete column transition section (the first transition section), and the composite tube-constrained steel reinforced concrete column transition section (the second conversion section) and the steel reinforced concrete cover beam conversion section (cover beam conversion section) is connected with the reinforced concrete cover beam. The steel pipe in the double-walled hollow pier column is connected to the steel pipe in the first conversion section through the first steel partition, and then connected to the lower end of the steel frame in ...

Embodiment 3

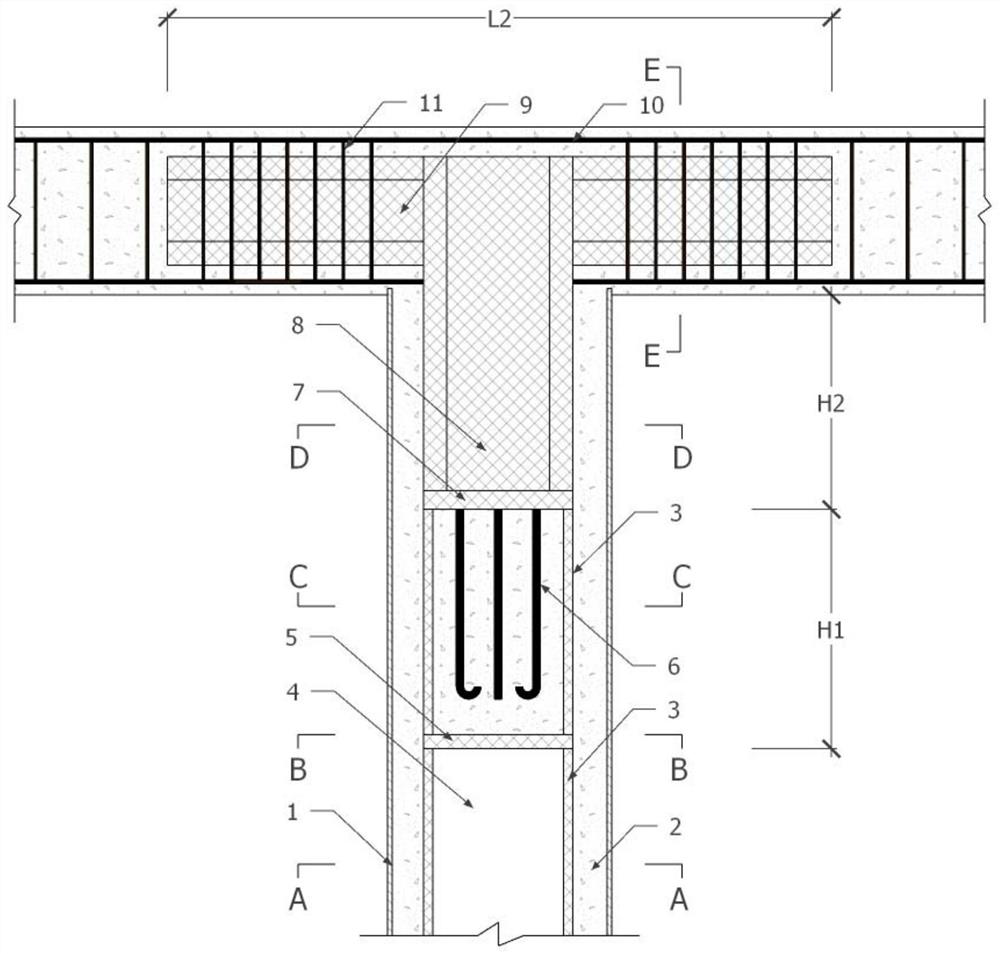

[0073] This embodiment provides a double-walled hollow pier column and a steel-reinforced concrete cover beam cast-in-place connection node, and the node includes a first transition section and a cover beam transition section.

[0074] In this embodiment, the composite pipe-concrete-steel pipe double-walled hollow pier passes through the composite pipe-concrete-steel pipe double-pipe solid concrete column conversion section (the first conversion section) and the steel reinforced concrete cover beam conversion section (cover beam conversion section). section) is connected to the steel reinforced concrete cover beam. The steel pipe in the double-wall hollow pier column is connected to the steel pipe in the first conversion section through the first steel partition, and then the upper end of the steel pipe in the first conversion section is extended into the conversion section of the cover beam and connected to the conversion section of the cover beam The inner steel frame is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com