Concrete member and pouring method thereof

A concrete and component technology, applied in the direction of building components, buildings, structural elements, etc., can solve problems such as breakage, deflection of horse stool, failure of support function, etc., to prevent deviation, save welding process, and simplify construction technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

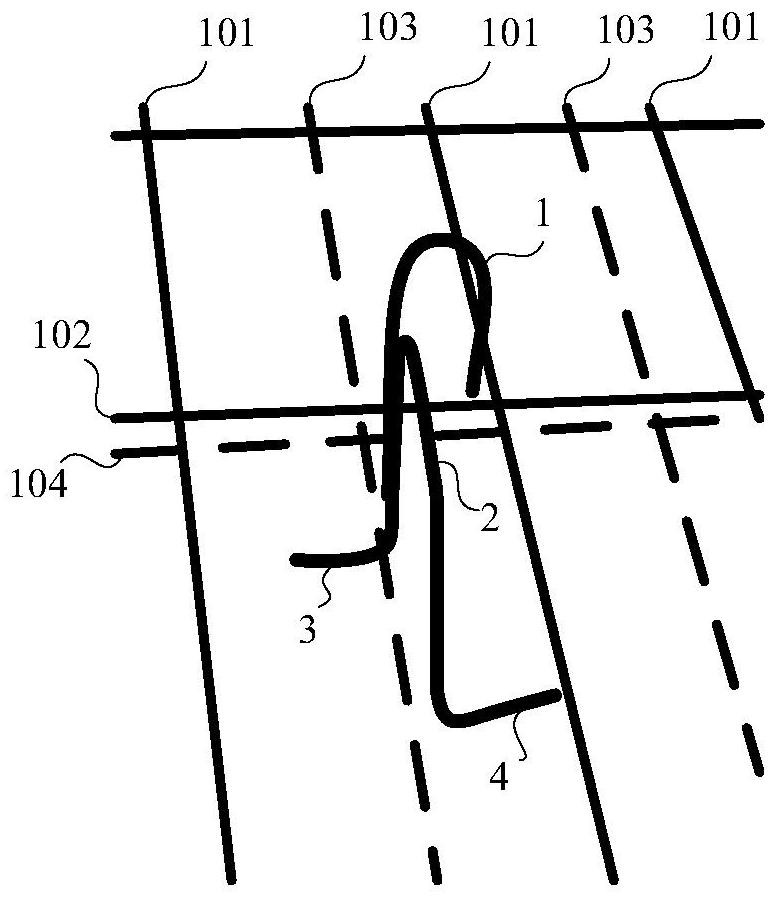

[0051] The first specific embodiment of the present invention provides a concrete member, which includes upper steel bars, lower layer steel bars and horse stool bars.

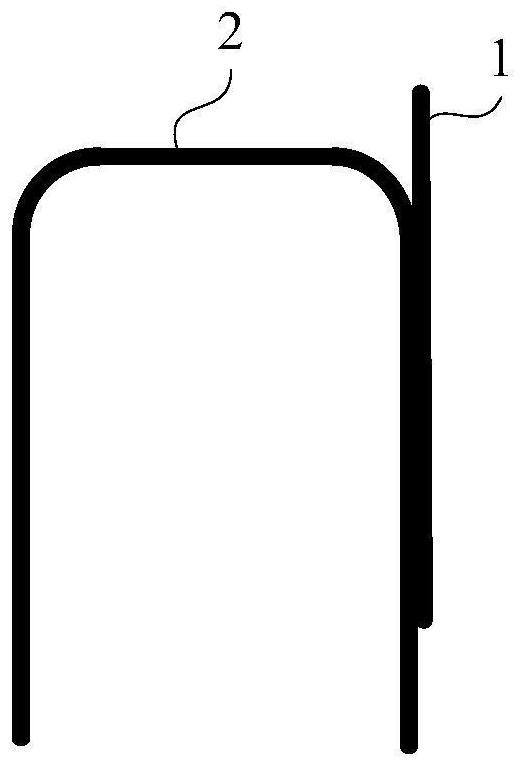

[0052] For details, please refer to Figure 2 to Figure 4 , the horse stool bar includes a positioning hook 1, a support bar 2, a first vertical strut, a second vertical strut, a first leg 3, and a second leg 4. in:

[0053] The positioning hook 1 is located on the top of the horse stool bar, and the opening of the positioning hook 1 is facing downward, and is used to hook down the first reinforcing bar unit 101 in the upper layer of reinforcing bars;

[0054] The support cross bar 2 is used to support the second steel bar unit 102 in the upper layer of steel bars. The second steel bar unit 102 is located below the first steel bar unit 101 and is perpendicular to the first steel bar unit 101. Therefore, the plane where the positioning hook is located and the support cross bar 2 vertical;

[0055] The first ...

no. 2 Embodiment

[0079] See Figure 5 , the second specific embodiment of the present invention provides a horse stool tendon, the difference between this horse stool tendon and the horse stool tendon in the above-mentioned first specific embodiment is only that: the bottom of the horse stool tendon can also be provided with a third leg 5 and the fourth leg 6. in:

[0080] The third leg 5 and the fourth leg 6 are located at the bottom of the first vertical strut and the second vertical strut respectively and are fixedly connected thereto. A vertical strut, the support cross bar 2, and the second vertical strut are located in the same vertical plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com