Building external wall heat preservation and coating spraying auxiliary fiber net spraying device

A technology for building exterior walls and spraying equipment, which is applied in the direction of architecture and building structure, can solve the problems of different regions of personnel, difficult management, high labor costs, etc., and achieve saving human resources, good social value and economic value, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

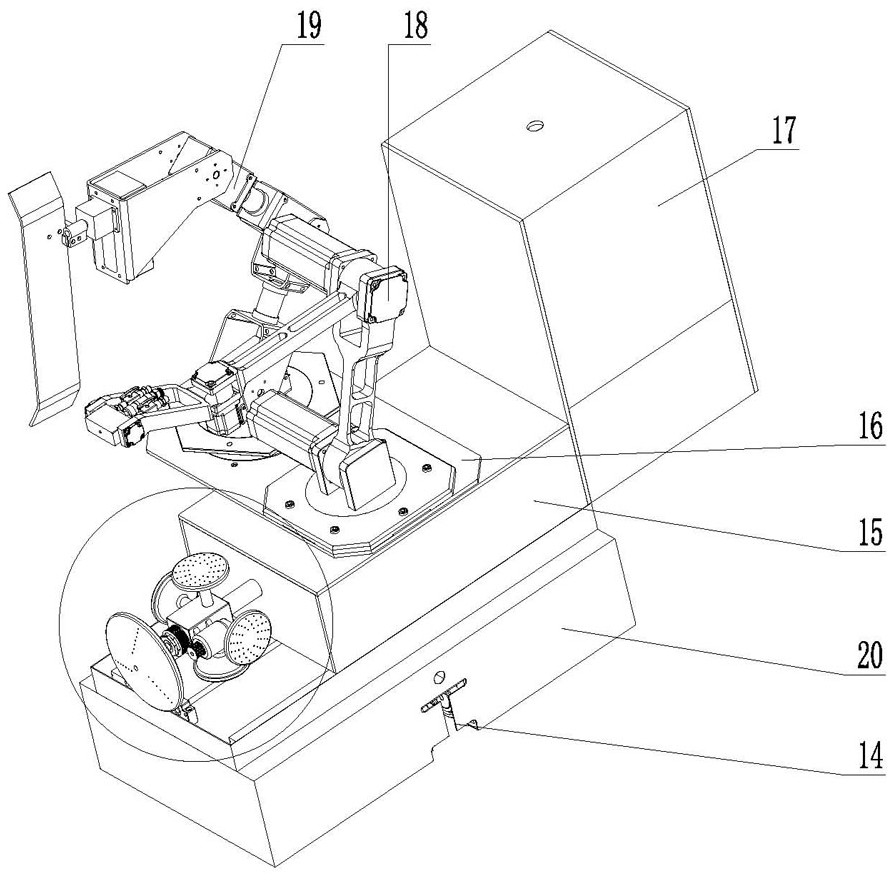

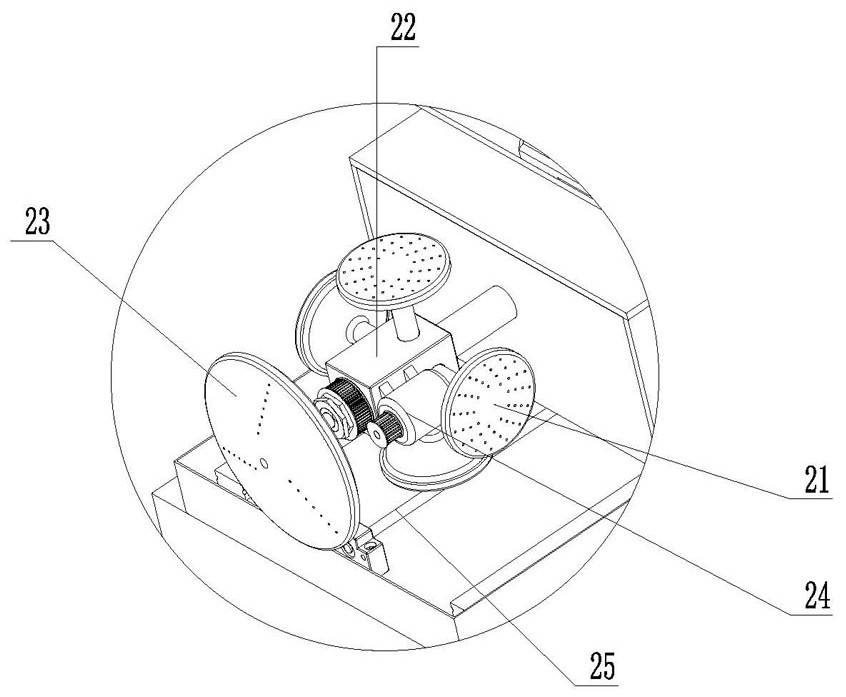

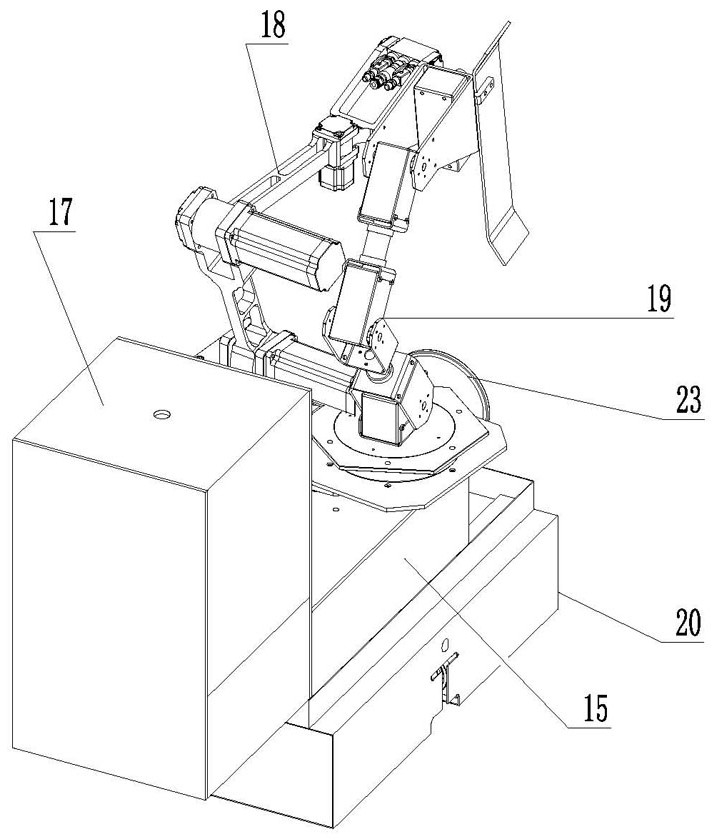

[0024] Embodiment: The present invention is applied to the spraying equipment for building exterior wall insulation and coating machinery construction. The building exterior wall insulation and coating machinery construction spraying equipment includes a frame structure 1, which is characterized in that: the frame structure 1 is provided with a lifting frame 7, and the lifting frame 7 is provided with thermal insulation material spraying equipment 9, and thermal insulation material spraying equipment 9 is connected with feeding equipment.

[0025] The frame structure 1 includes columns 5 arranged outside the outline of the building, the lifting frame 7 is arranged between the two columns 5, the guiding mechanism of the lifting frame 7 is arranged on the column 5, and the lifting frame 7 is arranged on the frame structure 1 lifting traction mechanism.

[0026] The column 5 is provided with a vertical rack 10, and the lifting frame 7 is provided with a lifting gear 11 cooperatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com