Debugging device for extra-high-voltage earthing switch

A grounding switch and ultra-high voltage technology, applied in the field of ultra-high voltage grounding switch debugging devices, can solve the problems of porcelain insulator and static contact damage, failure to form modular production, and low debugging efficiency, so as to increase production debugging efficiency and shorten debugging The effect of time and production process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

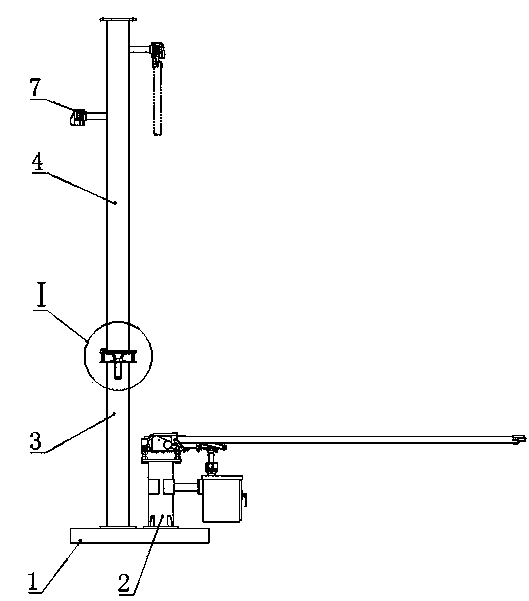

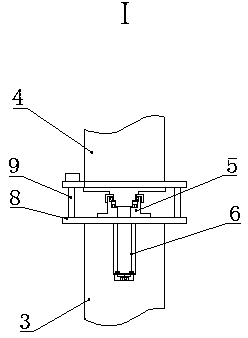

[0010] Such as figure 1 , 2 As shown, it includes support base 1, debugging mounting base 2, lower fixed pillar 3, upper movable pillar 4, fixed shaft 6, bearing seat 5, equivalent static contact 7, flange 8 and positioning pin 9.

[0011] The above-mentioned support base 1 is fixed with a commissioning installation seat 2 for installing the grounding switch base and the grounding knife switch, and an equivalent support instead of a porcelain insulator.

[0012] The equivalent pillar is positioned at one side of the debugging mount 2, and it comprises a lower fixed pillar 3 and an upper movable pillar 4, and a fixed shaft 6 is installed on the bottom end of the upper movable pillar 4, and the axis of the fixed axle 6 is in line with the upper movable pillar 4 and the upper movable pillar 4. The axes of the lower fixed pillars 3 are coincident. The top of lower fixed pillar 3 is equipped with bearing seat 5, and fixed shaft 6 is installed in the bearing seat 5 by bearing, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com