Gas self-closing valve

A gas self-closing valve, valve core technology, applied in the direction of lift valve, valve details, safety valve, etc., can solve problems affecting the normal use of gas, misoperation, etc., to reduce misjudgment and misoperation, stable use, reduce misuse effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

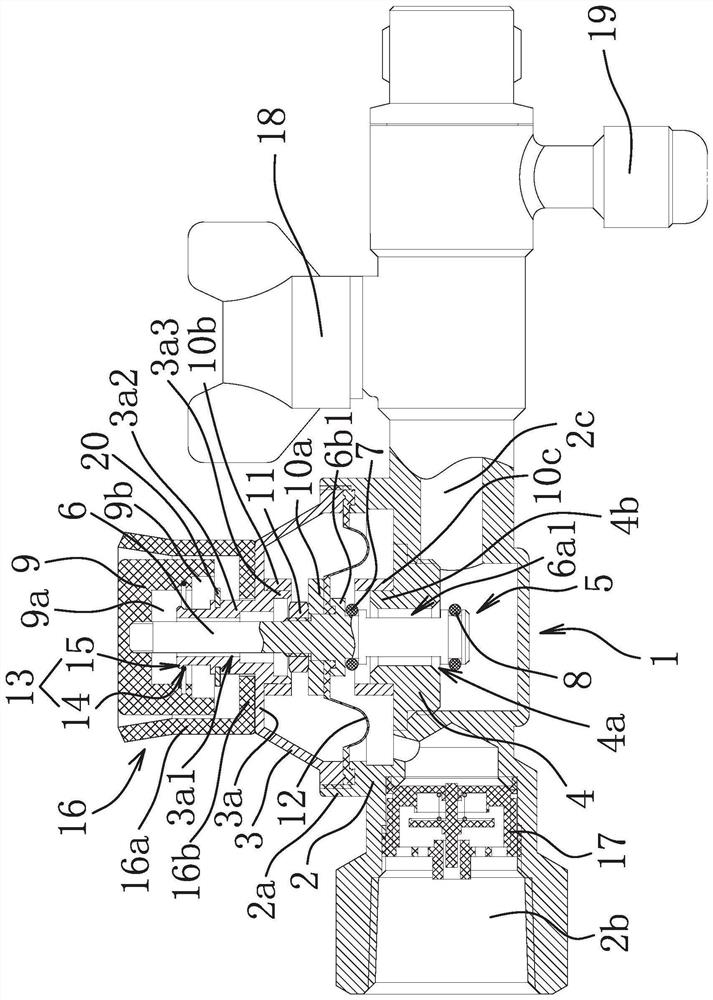

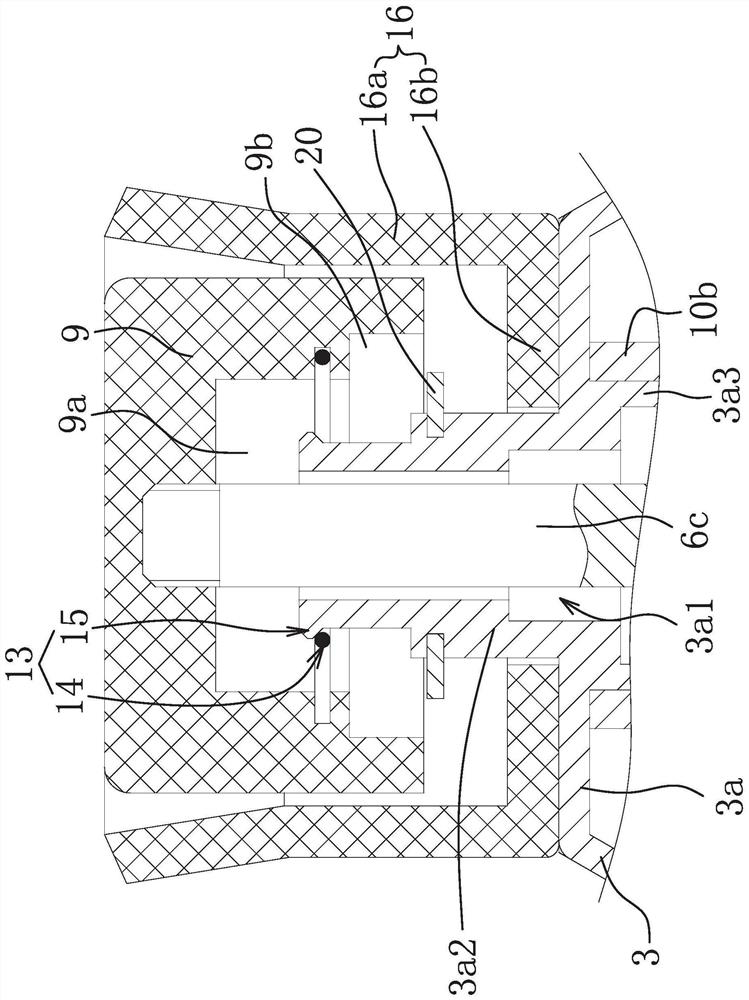

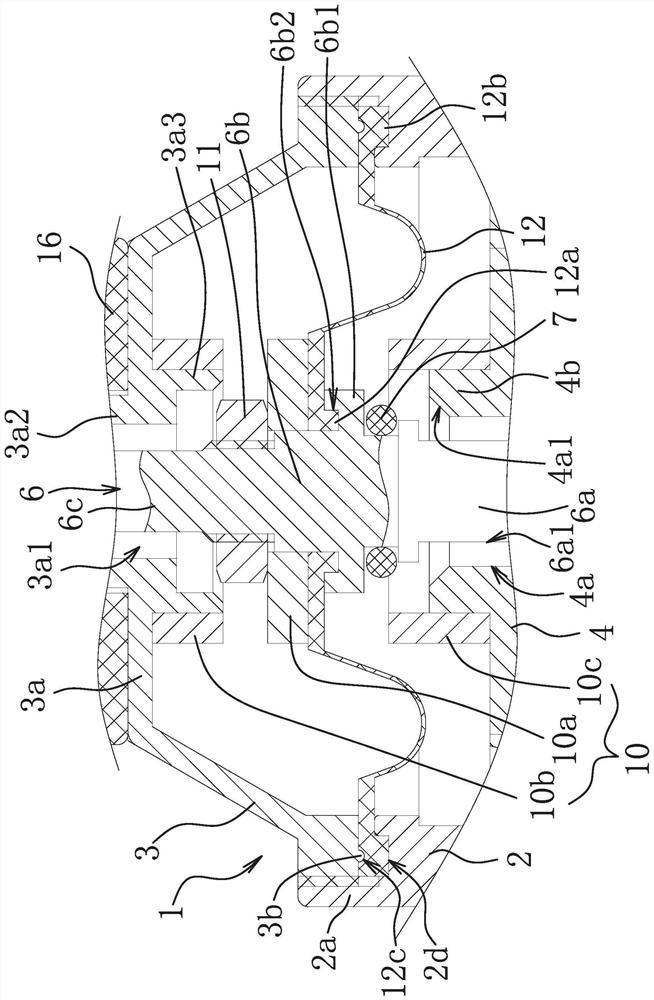

[0044] like Figure 1-Figure 9 As shown, a gas self-closing valve includes a valve body 1 and a valve core 5, a valve hole 4a is opened in the valve body 1, a film 12, a magnetic attraction assembly 10 and a valve control valve are arranged between the valve body 1 and the valve core 5. Structure 13, through the film 12 and the valve control structure 13, the valve core 5 can be hovered at the normal valve opening position to keep the valve hole 4a open, and the valve core 5 can pass through the magnetic attraction after moving downward and upward at the normal valve opening position. The assembly 10 makes the valve core 5 close and keep the valve hole 4a closed. When the spool 5 moves downwards, the spool 5 closes the valve hole 4a through the magnetic assembly 10 and keeps it closed, the spool 5 is in the underpressure closed valve position; when the spool 5 moves upwards, the magnetic assembly 10 makes the valve When the spool 5 closes the valve hole 4a and keeps it closed...

Embodiment 2

[0059] like Figure 10 As shown, the connection structure between the cover body 3 and the body 2 is different from that of the first embodiment, and the other structures are the same as those of the first embodiment. The outer edge of the lower end surface of the cover body 3 has a protruding ring-shaped connecting ring 2a, the upper end of the body 2 is inserted into the connecting ring 2a to form a threaded connection, and the outer edge of the film 12 is pressed and fixed on the lower end surface of the cover body 3 and the upper end surface of the body 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com