Thermocouple type analog quantity input module based on SPARC microcontroller

A technology of microcontroller and input module, applied in simulators, program control, heat measurement, etc., can solve problems such as the inability to effectively reduce the impact, and achieve the effect of meeting the needs of temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

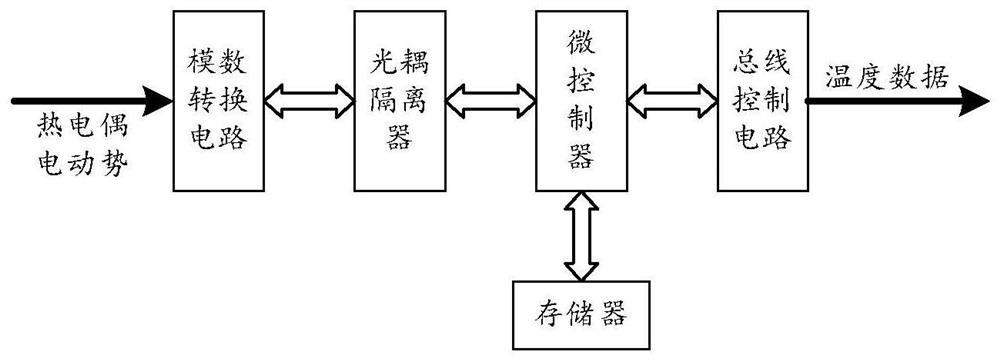

[0024] A thermocouple type analog input module based on SPARC microcontroller, its composition block diagram is as follows figure 1 As shown, including: analog-to-digital conversion circuit, optocoupler isolator, microcontroller, memory, bus control circuit.

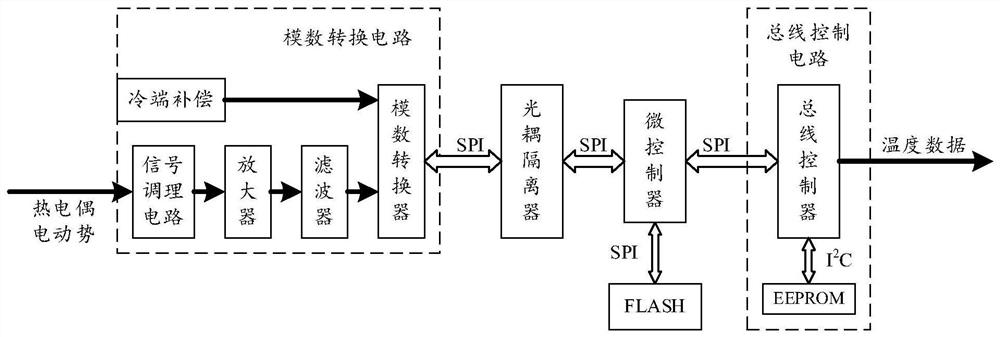

[0025] The thermocouple analog input module converts the electromotive force of the thermocouple that has been compensated by the cold junction into temperature data, and realizes the temperature measurement of the environment at the end of the thermocouple. The detailed composition block diagram is as follows: figure 2 shown, including:

[0026] The analog-to-digital conversion circuit converts the electromotive force analog generated by the thermocouple due to the thermoelectric effect into a digital value.

[0027] Analog-to-digital conversion circuits include cold junction compensation, sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com