Framework forming axial flow turbine blade design method

A turbine blade and design method technology, applied in the field of turbomachinery, can solve the problems of reducing the secondary flow action area, deterioration of the blade tip secondary flow, mixing loss, etc., and achieve good versatility, wide applicability, and large application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail through specific embodiments below.

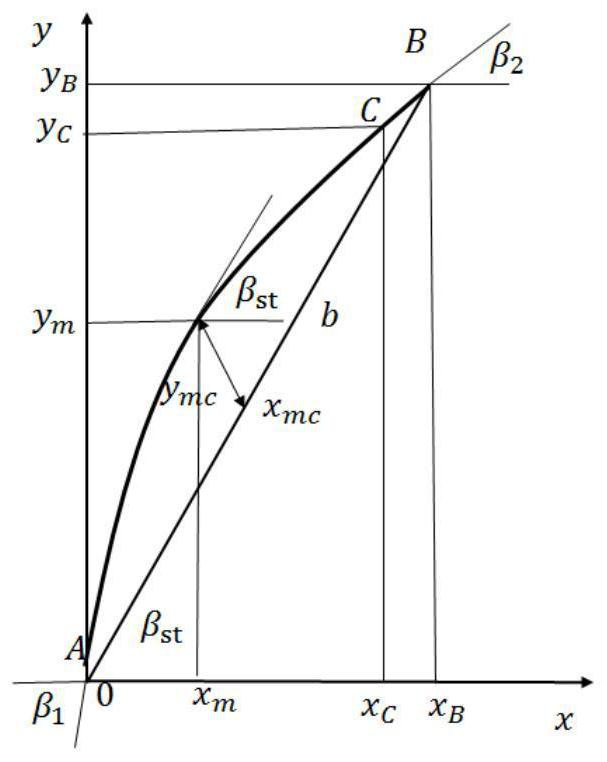

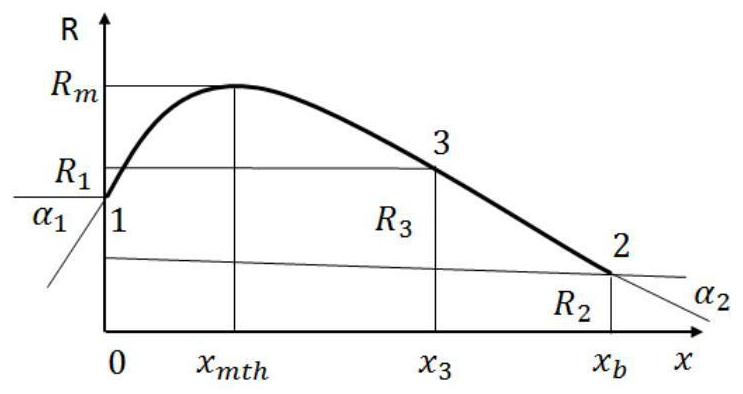

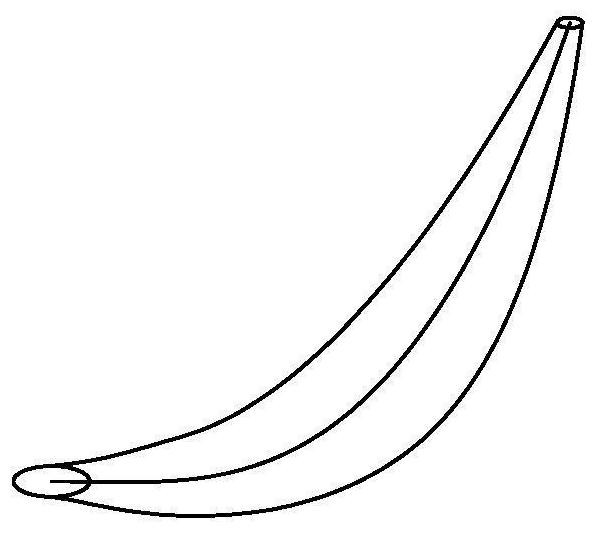

[0045]A design method for axial-flow turbine blades with skeleton forming, which decomposes the blade design into three parts: mid-arc design, thickness distribution design, and stacking line design; among them, the mid-arc design is to set two control parameters on the mid-arc The thickness distribution design is to set two control parameters on the thickness distribution to characterize the thickness distribution, which is used to adjust the blade shape; the stacking line design is to express the stacking line in the form of parameters to control the blade along The radial camber produces straight blades and twisted blades; the characteristic section formed by the middle arc and thickness distribution is arranged according to the curved twisted line formed by the radial installation angle and the stacking line to generate adjustable three-dimensional blades.

[0046] Both t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com