Eccentric block device with built-in outer rotor servo motor

A technology of servo motor and eccentric block, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problem that the eccentric block can reduce the rotational vibration force of the built-in outer rotor servo motor, and the eccentric block is not equipped with a counterweight structure, reducing the practicality of the eccentric block sexual issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

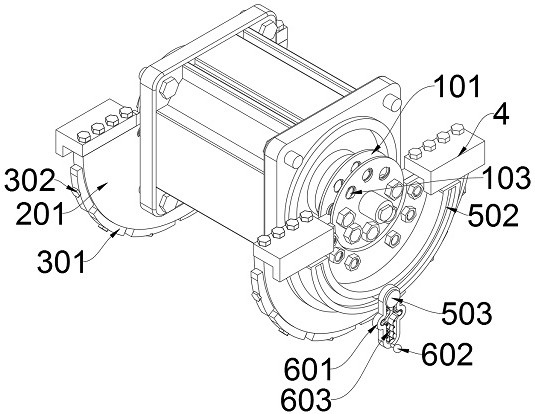

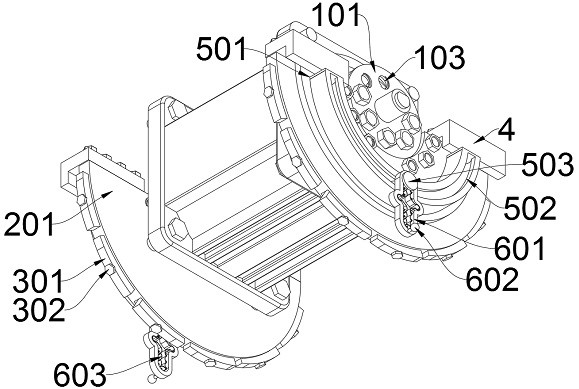

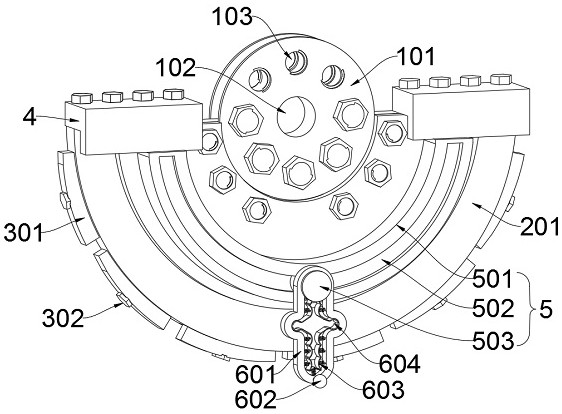

[0036] as attached figure 1 to attach Figure 10 Shown:

[0037] The invention provides an eccentric block device with a built-in outer rotor servo motor, which includes a fixed structure 1; the outer and inner ends of the fixed structure 1 are respectively interspersed and installed with an adjustment structure 2; the lower end of the adjustment structure 2 is hollow and fixed with a load-bearing structure 3; A pair of L-shaped grooves 4 are respectively fixedly installed on the middle upper ends of the left and right sides of the adjustment structure 2; the outer end faces of the adjustment structure 2 are respectively vertically connected and installed in parallel with the weight-increasing structure 5; The fixed structure 1 includes a main shaft cylinder 101, a central hole groove 102 and an adjustment hole 103. The main shaft cylinder 101 is a hollow cylindrical structure similar to an I-shape on the side, and the central inner side of the main shaft cylinder 101 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com