Energy-saving and environment-friendly furnace end

An energy-saving, environmentally friendly, burner technology, which is applied to gas fuel burners, combustion methods, combustion types, etc., can solve the problems of affecting the service life of the burner, easy to block the gas outlet, and low gas utilization rate, and achieves high heat. value, good energy saving effect and complete combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

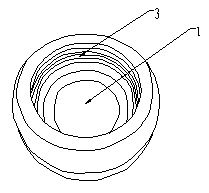

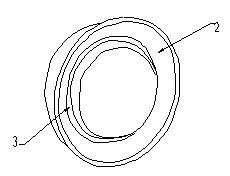

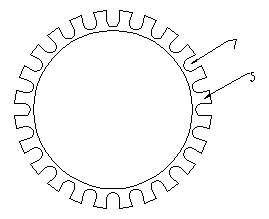

[0016] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , the energy-saving and environment-friendly burner head of this embodiment is composed of a combustion chamber 1 and a gas chamber 2, the gas chamber 2 surrounds the combustion chamber 1, the bottom of the combustion chamber 1 is in a closed state, and a gas chamber 2 and the combustion chamber 1 are provided There is a partition wall 3, and many air outlet holes 4 are distributed on the partition wall 3. The partition wall 3 is formed by stacking a plurality of spacers A5 and a plurality of spacers B6 alternately, and the thickness of the spacers A5 and the spacers B6 is the same. The gasket A5 is an annular gasket, and a plurality of grooves A7 opening outward are distributed on the gasket A5 in an annular array. The gasket B6 is also an annular gasket, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com