Equipment for producing high-quality and less-dust cement

A high-quality, cement-based technology, applied in the field of cement equipment, can solve the problems that cement powder is difficult to pass through the discharge port at the lower end, and the cement powder accumulates and is discharged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

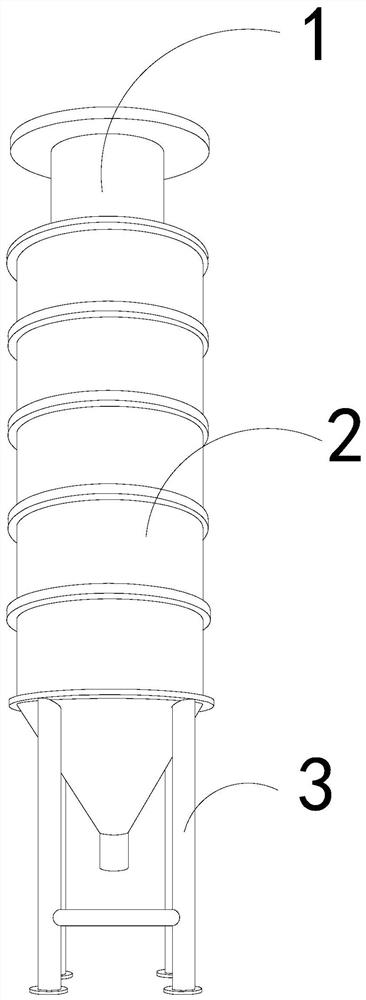

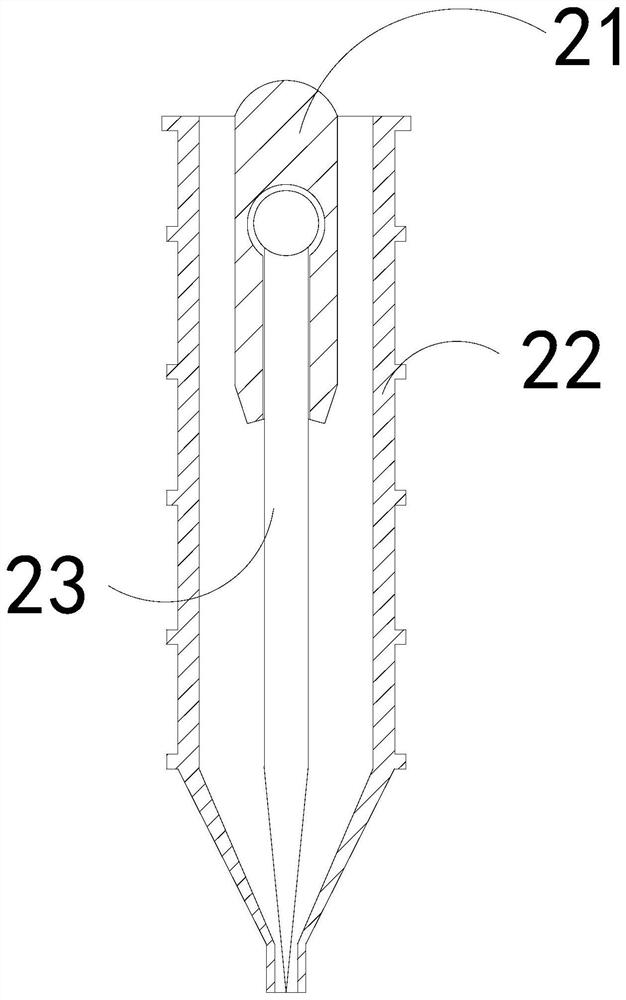

[0027] The present invention provides an equipment for producing high-quality dust-less cement, the structure of which includes a feed pipe 1, a cement tank 2, and a base bracket 3, the feed pipe 1 is embedded in the upper end of the cement tank 2, and the cement tank 2 Welded with the base bracket 3; the cement tank 2 includes a solid plate 21, a tank body 22, and a breaking mechanism 23, and the solid plate 21 and the tank body 22 are an integrated structure, and the breaking mechanism 23 and the center The fixed plate 21 is movable and engaged.

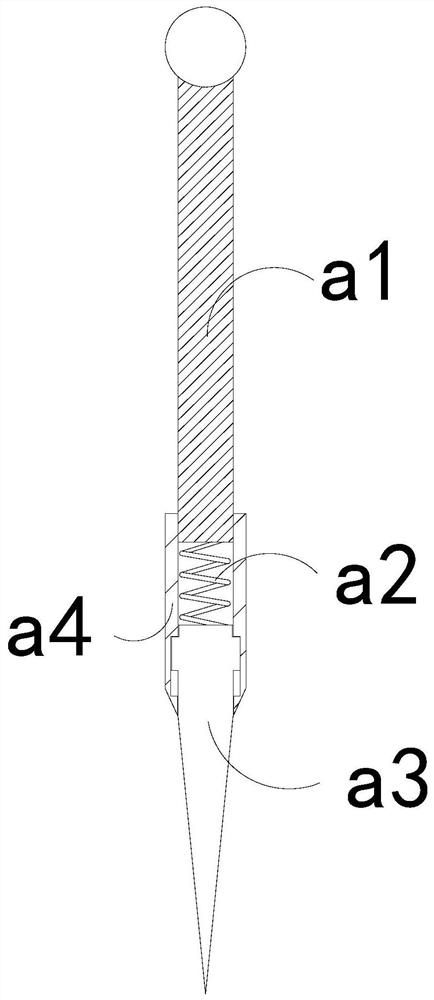

[0028] Wherein, the dispersing mechanism 23 includes an connecting rod a1, an elastic strip a2, a lower stretching plate a3, and a guide frame a4, the elastic strip a2 is installed between the connecting rod a1 and the lower stretching plate a3, and the lower stretching plate a3 Engaged with the pedestal a4, the pedestal a4 and the connecting rod a1 are an integrated struct...

Embodiment 2

[0034] For example Image 6 -example Figure 8 Shown:

[0035] Wherein, the overhanging block a34 includes a sealing plate c1, a booster ring c2, and a solid plate c3. The sealing plate c1 is embedded in the outer position of the booster ring c2. Embedded connection, the sealing plate c1 is provided with two, and evenly distributed symmetrically on the upper and lower sides of the solid plate c3, through the booster ring c2 can generate a continuous outward thrust on the sealing plate c1.

[0036] Wherein, the central solid plate c3 includes a frame c31, an extra push bar c32, an impact block c33, and a front plate c34. c31 is movable and engaged, the front plate c34 is embedded and fixed on the left side of the frame c31, the impact block c33 is made of alloy steel with high density, and the impact block c33 can follow the forward inertial force of the object to the front The impact is generated on the inner side of the plate c34.

[0037] Wherein, the front panel c34 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com