Load sensitive system and engineering hoisting machinery

A load-sensitivity, highest load pressure technology, applied in the direction of mechanical equipment, servo motors, fluid pressure actuators, etc., can solve the problem of poor coordination of compound actions of multiple working links, reduced flow distribution performance, and extremely uneven flow area matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

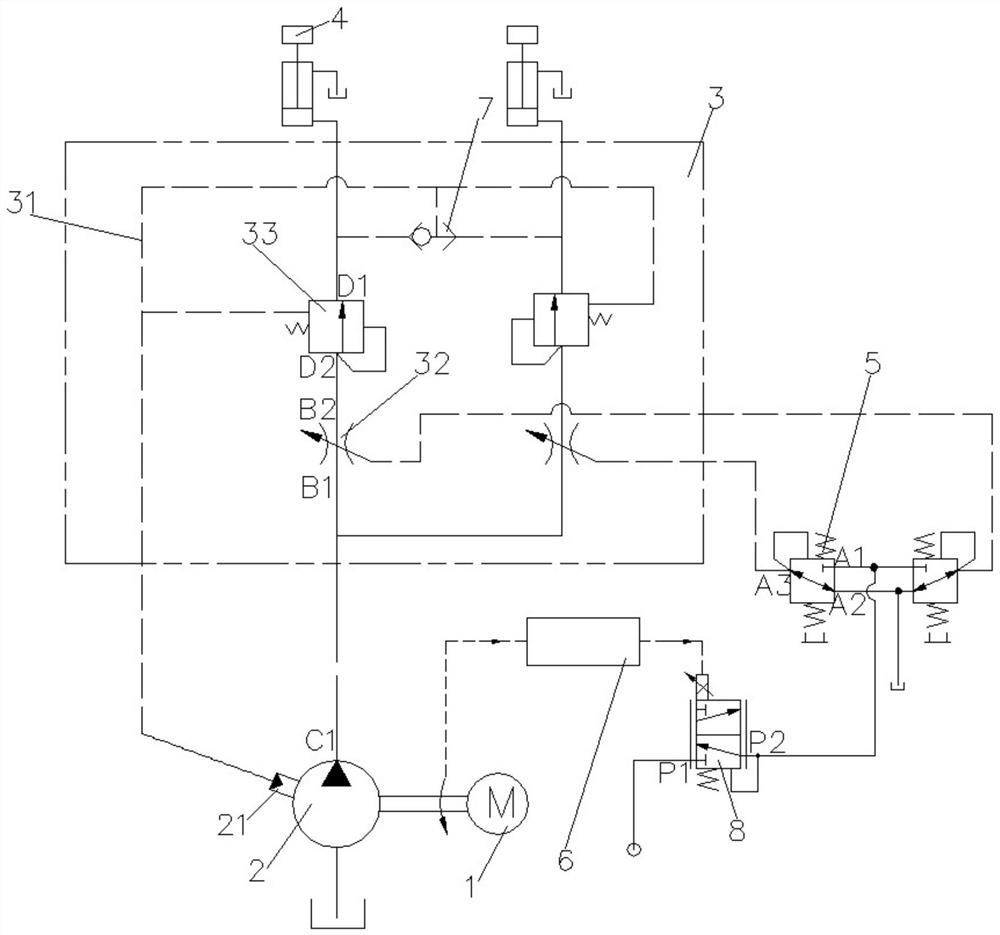

[0053] As a preferred implementation, the pressure control device includes a first oil port A1, a second oil port A2 and a third oil port A3, and the third oil port A3 of the pressure control device can be selectively connected with the first oil port A1 or The second oil port A2 is connected, and the third oil port A3 of each pressure control device is connected to each of the actuators 4 through the post-valve compensation load-sensitive multi-way valve 3 in one-to-one correspondence, under the action of the control unit 6 , the maximum output pressure of the third oil port A3 of the pressure control device is limited to control the flow flowing into the corresponding actuator 4 .

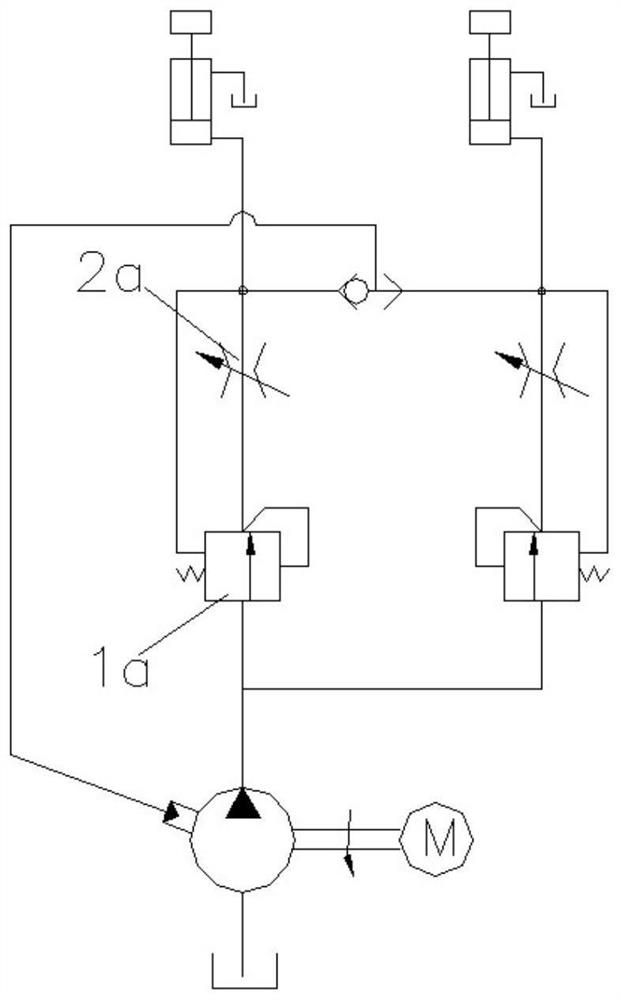

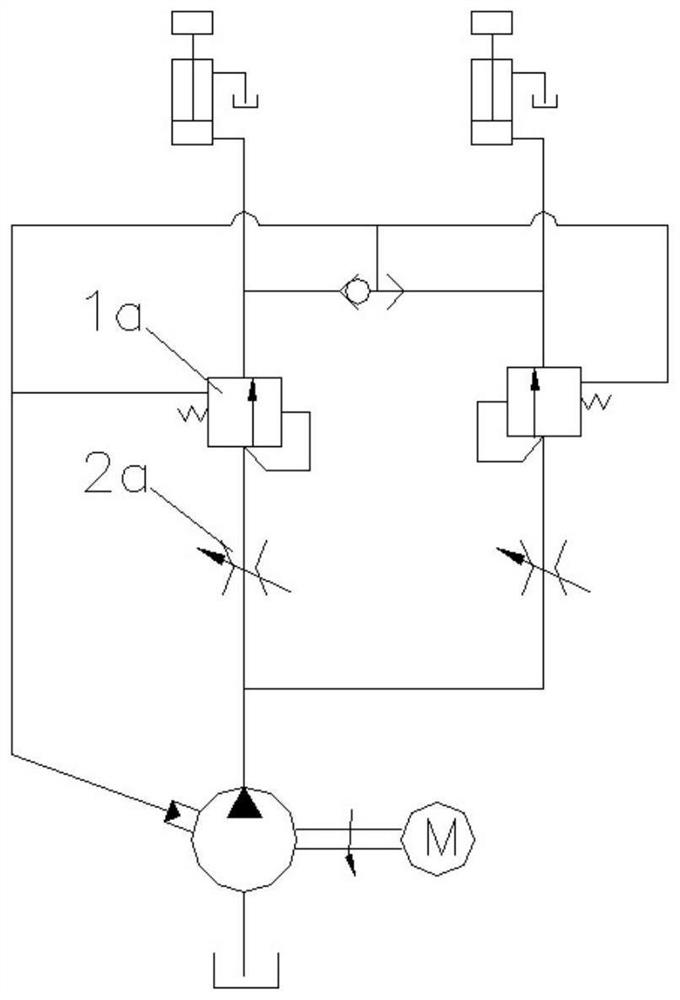

[0054] Conventionally, the post-valve compensation load-sensitive multi-way valve 3 includes multiple post-valve compensation working joints and the highest load pressure signal feedback oil circuit 31, and the post-valve compensation working joint includes a main valve 32 and a pressure compensat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com