Device and method for testing oil churning loss of spiral bevel gear

A technology of spiral bevel gear and testing method, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc. Problems such as measurement and oil churning loss of the side wall have a large impact, so as to save the production cycle, improve the test efficiency, and improve the test range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

[0034] The following will clearly and completely describe the examples of the present invention in conjunction with the accompanying drawings. In order to avoid too many unnecessary descriptions, well-known structures or functions will not be described in detail in the following examples. The examples represent only a part of the present invention, not all examples. In addition, certain quantitative expressions used in the following examples may allow certain changes in quantity without changing the basic function.

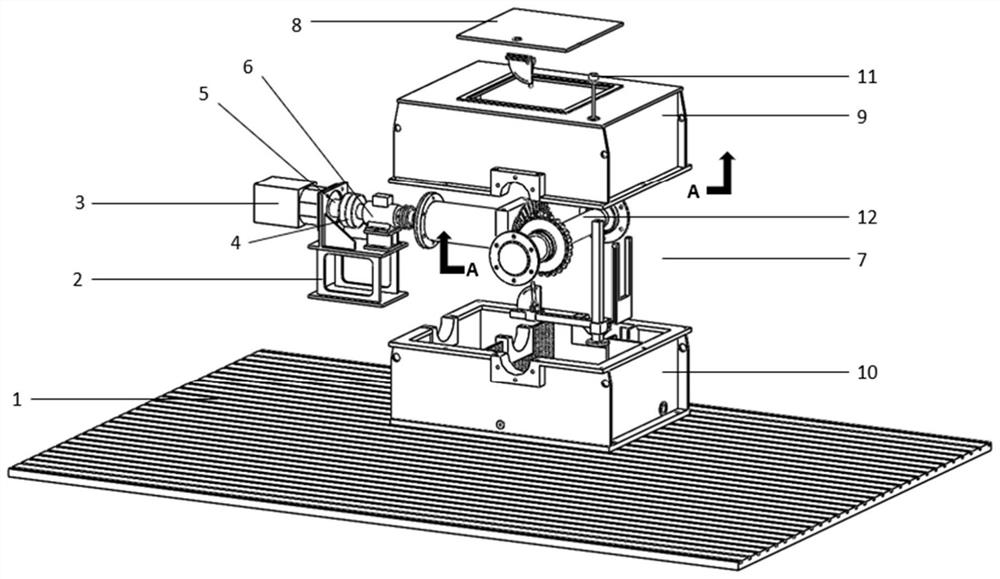

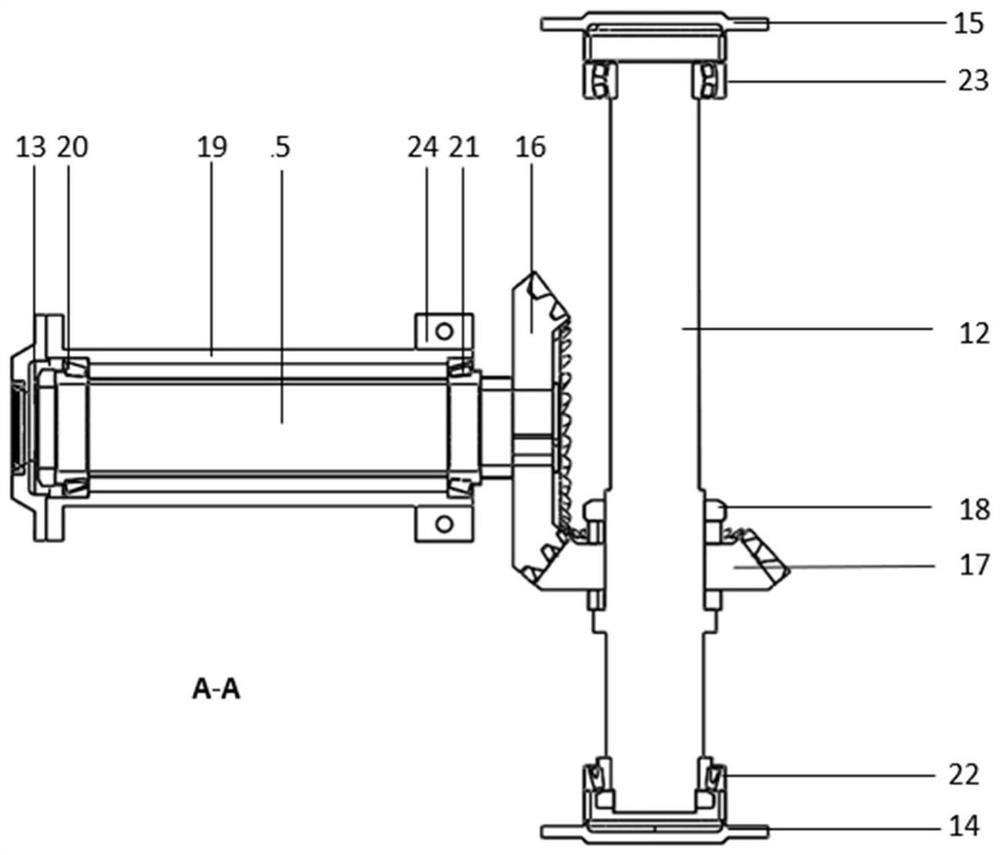

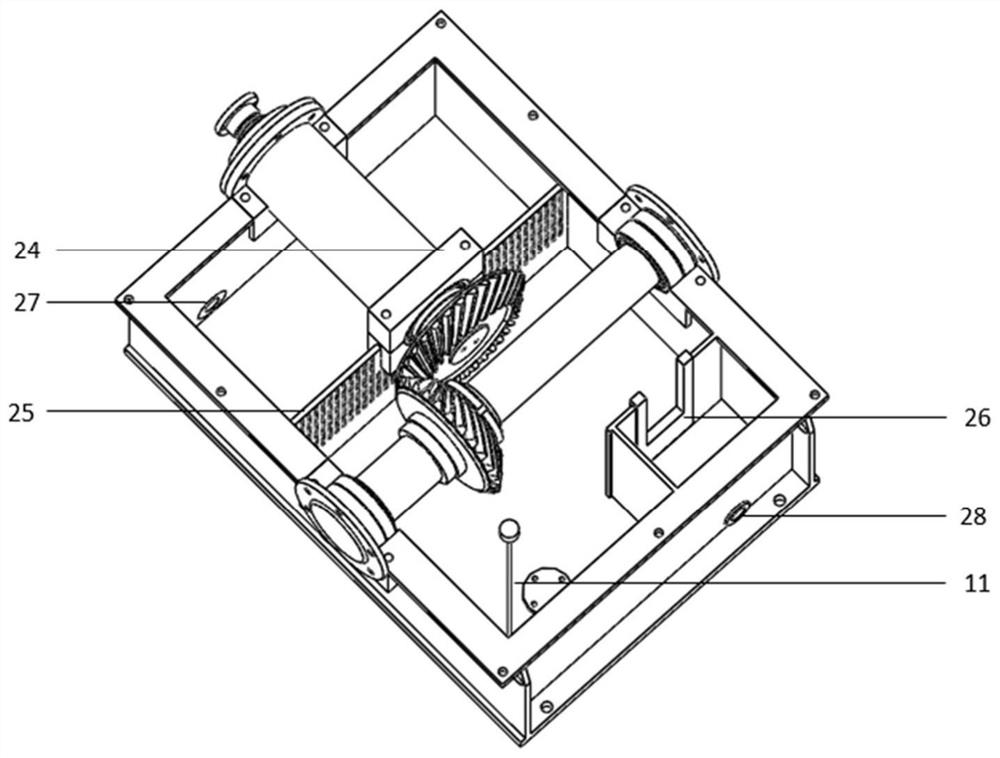

[0035] Such as figure 1As shown, a spiral bevel gear churning loss testing device includes a driving motor 3 and a gear box 7, the gear box 7 is provided with a driving main shaft 5 and a driven shaft 12, and one end of the driving main shaft 5 is connected to the output of the driving motor 3. Shaft connection, the other end of the driving main shaft 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com