A kind of online drying method of heating cigarette cut tobacco

A drying method and technology for shredded tobacco, which are applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of increased shredded shredded shreds, waste of shredded tobacco, etc., and achieve the effect of improving the whole shredding rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

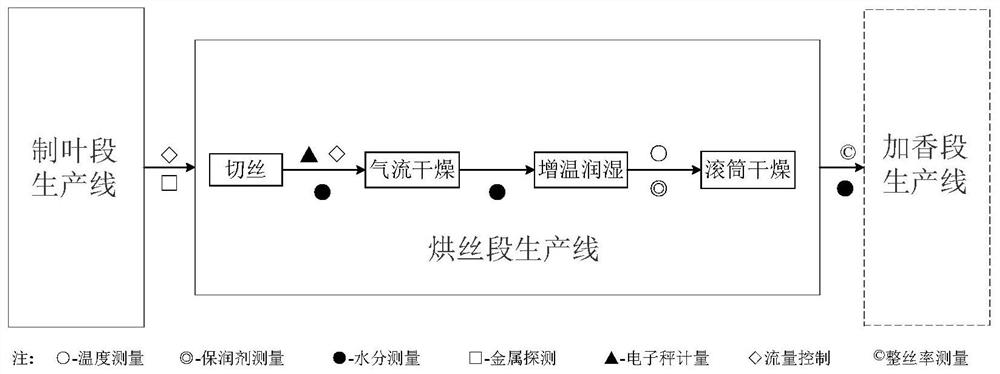

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Combined drying production mode of "high temperature airflow drying + low temperature drum drying"

[0030] Step 1) increasing the moisture content of natural tobacco leaves to 18.5% through the leaf making section, cutting into shreds, and controlling the width of shredded tobacco to be 1.0 mm;

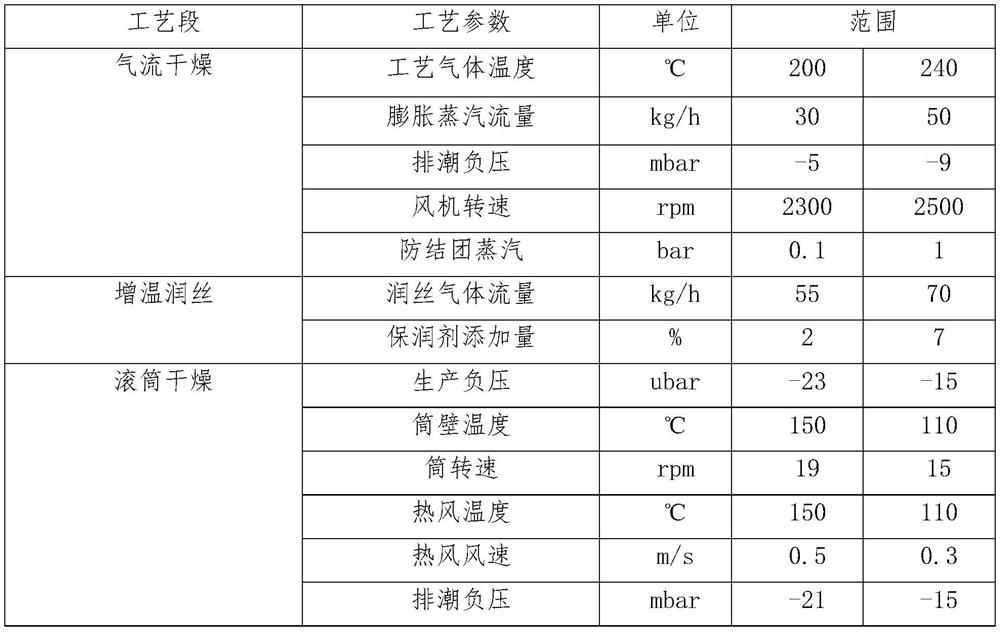

[0031] Step 2) carrying out high-temperature airflow drying treatment on the cut tobacco, and controlling the process gas temperature to be 230°C, the expansion steam flow rate to be 40kg / h, the negative moisture exhaust pressure to be -7mbar, the fan speed to be 2470rpm, and the anti-agglomeration steam to be 0.5bar;

[0032] Step 3) The cut tobacco is then subjected to drum drying treatment, and the control production negative pressure is -20ubar, the cylinder wall temperature is 130 ℃, the cylinder rotating speed is 17rpm, the hot air temperature is 130 ℃, the moisture exhaust negative pressure is -20mbar, and the cut tobacco moisture is reduced to 2.7 %, the whol...

Embodiment 2

[0033] Example 2 Combination drying production mode of "high temperature air drying + warming and moistening + low temperature drum drying"

[0034] Step 1) increasing the moisture content of natural tobacco leaves to 19.0% through the leaf making section, cutting into shreds, and controlling the width of shredded tobacco to be 1.0 mm;

[0035] Step 2) carrying out high-temperature airflow drying treatment with the cut tobacco, and controlling the process gas temperature to be 230 ° C, the expansion steam flow rate to be 40 kg / h, the negative moisture exhaust pressure to be -7 mbar, the fan speed to be 2470 rpm, and the anti-agglomeration steam to be 1 bar;

[0036] Step 3) Carry out temperature-warming and silk-conditioning treatment again, control the gas flow rate of temperature-warming and silk-conditioning to be 60kg / h, increase the temperature of cut tobacco to 83°C, and control the content of humectant 1,2-propylene glycol in cut tobacco to be 4%;

[0037] Step 4) The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com