Steel plate bending detection device

A plate detection device, detection device technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of steel plate angle detection, product scrapping, steel plate detection and other problems, and achieve the effect of preventing product scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

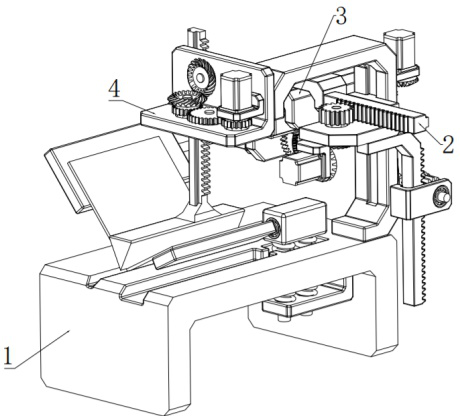

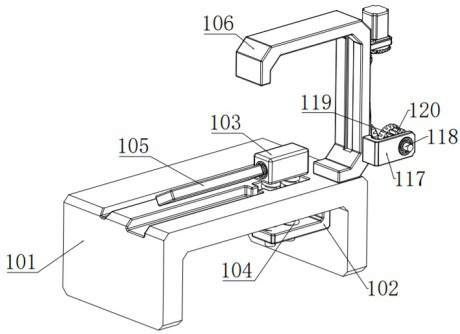

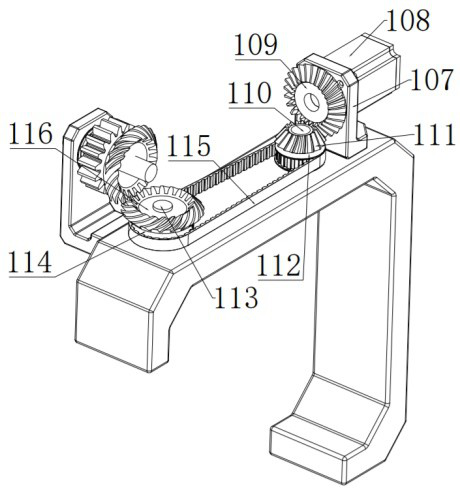

[0026] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 Shown is a steel plate bending detection device.

[0027] A bending detection device for a steel plate includes a support board detection device 1 , a translation device 2 , a rotation detection device 3 and a bending device 4 .

[0028] The support plate detection device 1 includes a support plate 106 and an upper driven spur gear 120 . The translation device 2 includes a slider 201 , a rack 203 , and a driven rack connecting plate 212 . The rotation detection device 3 includes a transmission housing plate 301 . The bending device 4 includes a connecting and fixing plate 401 .

[0029]The support plate 106 is fixedly mounted on the upper surface of the right side of the fixed bottom plate 101, the upper driven spur gear 120 is rotatably mounted on the driven shaft 118 and is located on the right side of the upper driven helical gear 119, and the slider 201 forms a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap