Multi-station marking machine

A marking machine and multi-station technology, applied in the field of marking machines, can solve problems such as large labor force, low efficiency, and unsafety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

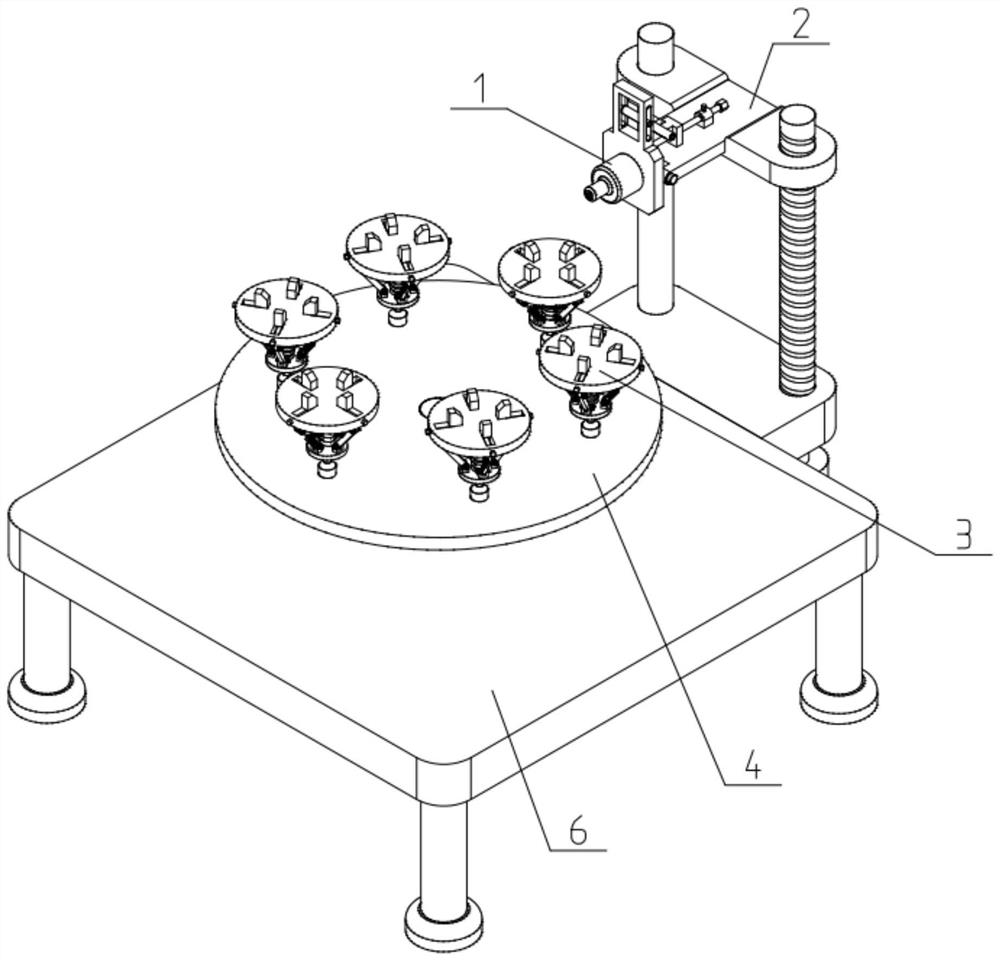

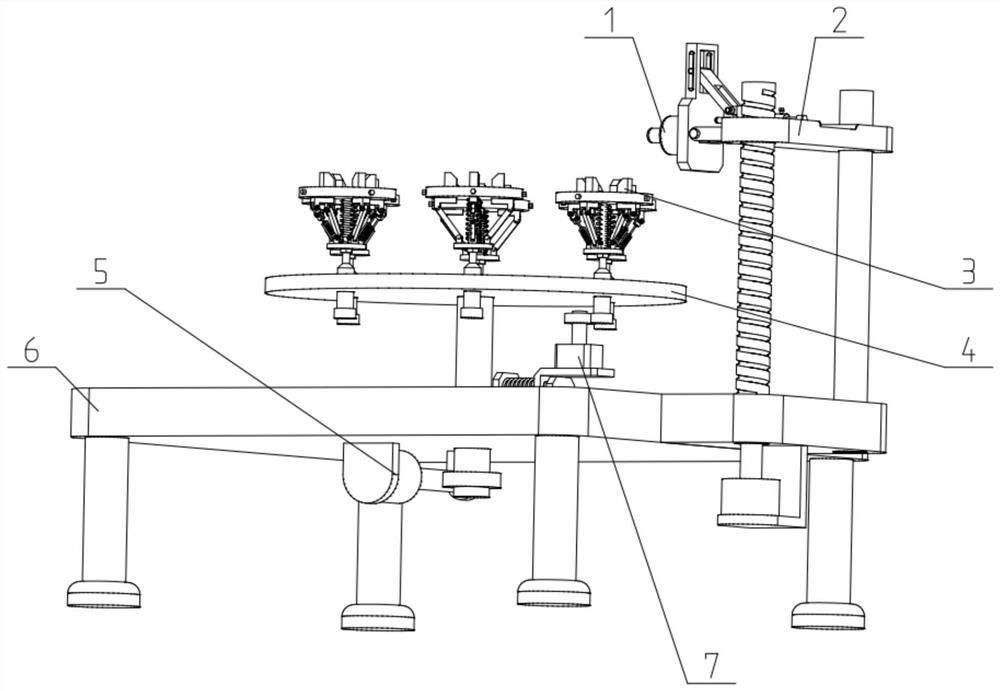

[0037] Such as Figure 1-11 As shown, a multi-station marking machine includes a laser marking machine 1, a marking machine mounting frame 2, a workpiece fixture 3, a rotating platform 4, a rotating drive mechanism 5 and a frame 6. The laser marking machine 1 fixed on the marking machine mounting frame 2; the marking machine mounting frame 2 is fixedly connected to the frame 6; the rotating drive mechanism 5 fixed on the frame 6 is connected to the rotating platform 4 , to drive the rotating platform 4 to rotate on the frame 6; the rotating platform 4 is uniformly surrounded and connected with a plurality of workpiece fixtures 3, so as to position the workpiece to be marked; the laser marking machine 1 cooperates It is arranged on the outside of the workpiece holder 3 . The present invention is equipped with a plurality of workpiece fixtures 3 inside, which can position a plurality of workpieces to be marked; inside is provided with a rotating platform 4 and a rotating drivin...

specific Embodiment approach 2

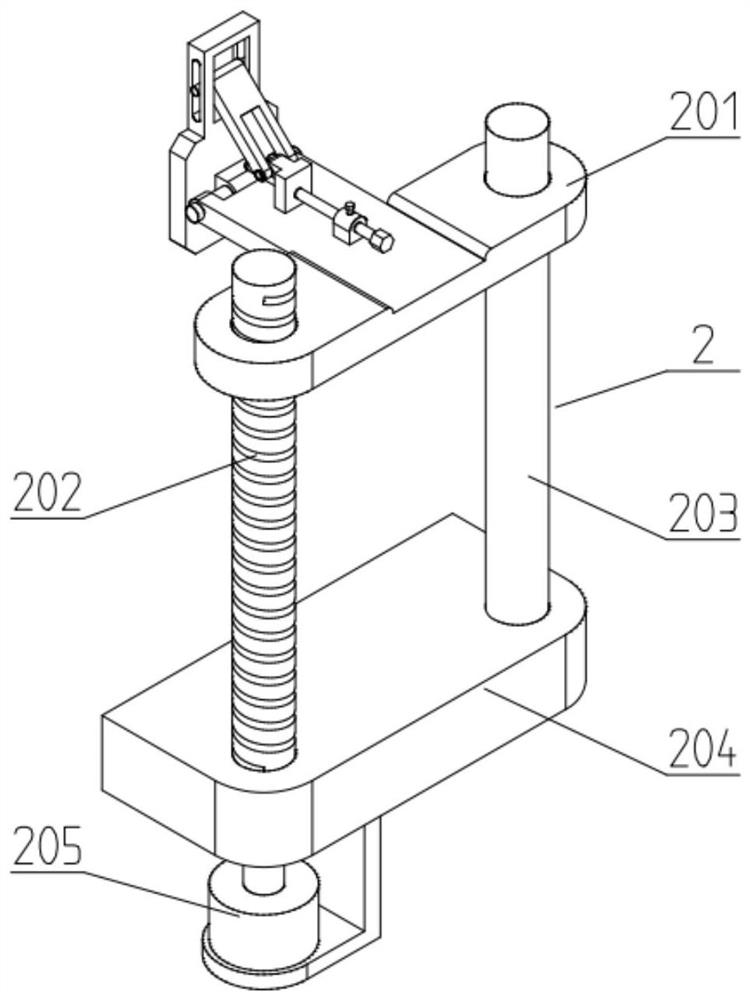

[0039] Such as Figure 1-11 As shown, the marking machine installation frame 2 includes an adjustable lifting frame 201, a screw 202, a vertical guide shaft 203, a horizontal seat 204 and a first servo motor 205; the horizontal seat 204 is fixed on the frame 6; A servo motor 205 is fixed on the cross seat 204 through a motor bracket; the output shaft of the first servo motor 205 is connected to the lead screw 202 through a coupling transmission; the lead screw 202 is rotated and fitted on the cross seat 204; The adjustable lifting frame 201 is connected to the bar 202 through screw transmission; the adjustable lifting frame 201 is slidably fitted on the guide vertical shaft 203; the guide vertical shaft 203 is fixed on the horizontal seat 204; the laser marking machine 1 Fixedly connected on the adjustable lifting frame 201. The height of the adjustable lifting frame 201 inside the marking machine installation frame 2 can be adjusted, thereby adjusting the horizontal position...

specific Embodiment approach 3

[0042] Such as Figure 1-11 As shown, the rotating platform 4 includes a platform body 401, a supporting shaft 402 and a worm wheel 403; the platform body 401 and the worm wheel 403 are respectively fixed on the upper and lower ends of the supporting shaft 402; the rotating drive mechanism 5 drives The worm gear 403 is connected; the platform body 401 is uniformly surrounded and fitted with a plurality of work clamps 3 . The quantity on the workpiece fixture 3 can be installed or disassembled according to actual needs.

[0043] The rotary drive mechanism 5 includes a second servo motor 501, a worm 502 and a rod holder 503; the second servo motor 501 is fixed on the frame 6 through a motor bracket; the output shaft of the second servo motor 501 One end of the worm 502 is connected through a coupling; the worm 502 is meshed and connected to the worm wheel 403;

[0044] After the second servo motor 501 is powered on, it can drive the worm 502 to rotate, and the worm 502 can dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com