A loading and unloading device for automatic deburring processing of minimally invasive surgical chuck parts

A minimally invasive surgery and deburring technology, which is applied in metal processing and other directions, can solve the problems of affecting the processing quality of chuck parts, low processing efficiency, and low degree of automation, and achieves benefits for mass processing, high feeding efficiency, and high loading efficiency. The effect of large amount of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

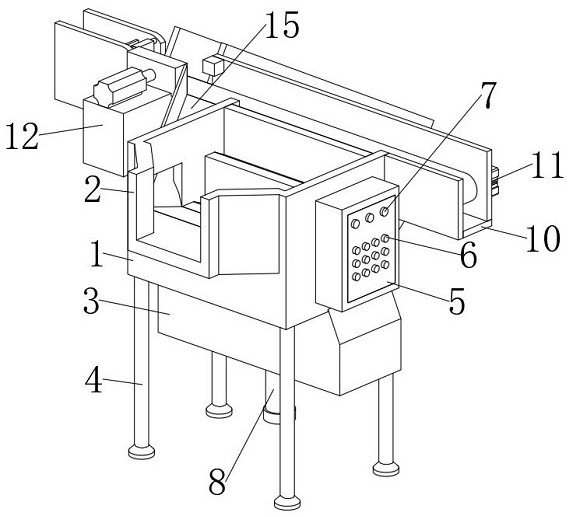

[0031] A loading and unloading device for automatic deburring processing of minimally invasive surgical chuck parts, such as Figure 1-2 As shown, it includes a storage box 1, the front end of the storage box 1 is fixedly installed with a feeding port 2, the lower end of the storage box 1 is fixedly installed with a mounting box 3 at the rear, and the lower end of the mounting box 3 is provided with a feeding mechanism 8, and the feeding The mechanism 8 extends into the storage box 1. The right end of the storage box 1 is fixedly installed with an electric control box 5. The upper right end of the electric control box 5 is provided with a power button 7, and the middle of the right end of the electric control box 5 is provided with a control button 6. The storage box 1 and the lower end of the installation box 3 are fixedly installed with the first support leg 4, the rear end of the storage box 1 is fixedly installed with a triangular mounting block 9, the upper end of the tria...

Embodiment 2

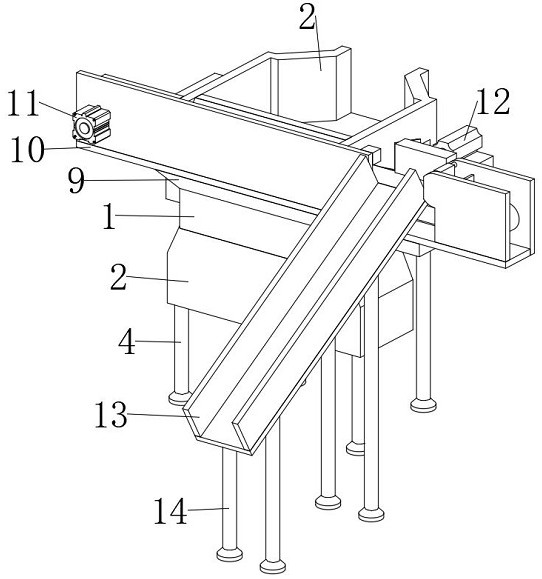

[0034] On the basis of Example 1, as Figure 3-6 As shown, a loading and unloading device for automatic deburring processing of minimally invasive surgical collet parts includes a storage box 1, the front end of the storage box 1 is fixedly installed with a feeding port 2, and the rear of the lower end of the storage box 1 is fixedly installed with an installation Box 3, the lower end of the installation box 3 is provided with a feeding mechanism 8, and the feeding mechanism 8 extends into the storage box 1, the right end of the storage box 1 is fixedly installed with an electric control box 5, and the upper right end of the electric control box 5 is provided with a power button 7. A control button 6 is arranged in the middle of the right end of the electric control box 5. The lower ends of the storage box 1 and the installation box 3 are fixedly installed with a first support leg 4. The rear end of the storage box 1 is fixedly installed with a triangular mounting block 9. The ...

Embodiment 3

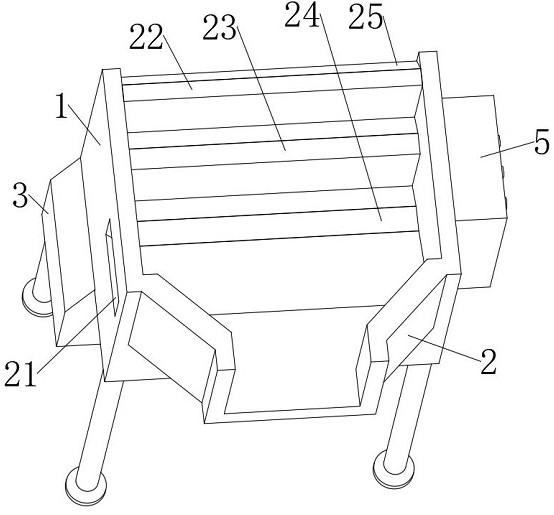

[0037] On the basis of Example 1, as Figure 6-7 As shown, a loading and unloading device for automatic deburring processing of minimally invasive surgical collet parts includes a storage box 1, the front end of the storage box 1 is fixedly installed with a feeding port 2, and the rear of the lower end of the storage box 1 is fixedly installed with an installation Box 3, the lower end of the installation box 3 is provided with a feeding mechanism 8, and the feeding mechanism 8 extends into the storage box 1, the right end of the storage box 1 is fixedly installed with an electric control box 5, and the upper right end of the electric control box 5 is provided with a power button 7. A control button 6 is arranged in the middle of the right end of the electric control box 5. The lower ends of the storage box 1 and the installation box 3 are fixedly installed with a first support leg 4. The rear end of the storage box 1 is fixedly installed with a triangular mounting block 9. The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap