Gasoline engine particle trap fuel economizer and regeneration control strategy

A particle filter and regeneration control technology, which is applied to the electronic control of exhaust treatment devices, exhaust devices, mufflers, etc., can solve the problem of reducing the passive regeneration opportunities of particle filters, fuel economy, driving performance, Unfavorable particle filter carbon cleaning and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

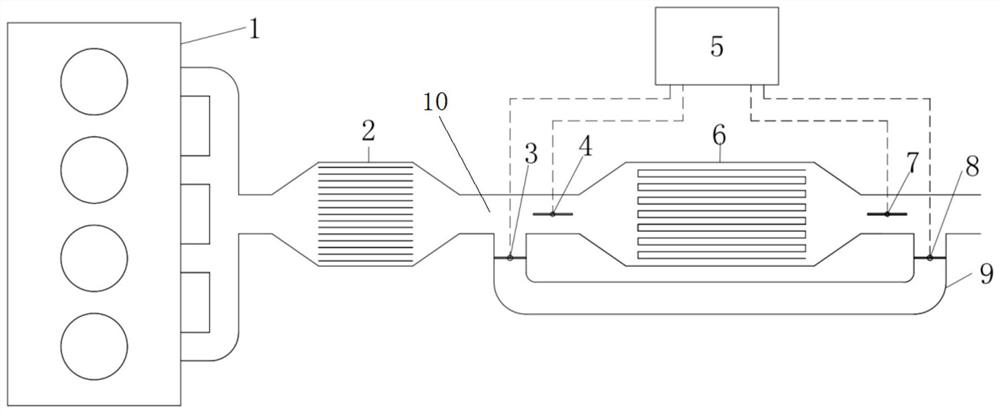

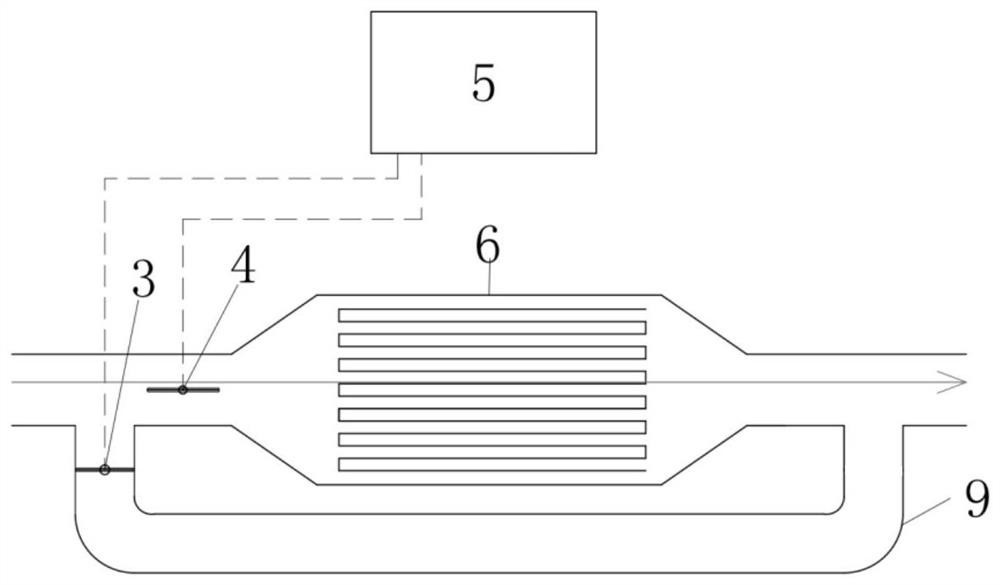

[0031] Embodiment 1. In this example, there are two solenoid valves, including solenoid valve one 3 and solenoid valve two 4, which saves the setting of solenoid valves and reduces the cost of the fuel-saving device for the gasoline engine particle filter. Solenoid valve one 3 is arranged at one end of bypass pipeline 9 , and solenoid valve two 4 is arranged on the main pipeline 10 at the front end of particle trap 6 . The controller is an electronic controller 5 .

[0032] The electronic controller 5 judges according to the central model temperature and model carbon amount of the particle trap in the controller algorithm, such as judging that there is no risk of burning the particle trap when the engine is cut off, and the accumulated carbon amount of the particle trap 6 is a safe carbon amount , it enters into the working mode of safe carbon quantity without oil cut-off.

[0033] The judgment of the model temperature and model carbon content of the particulate filter is bas...

Embodiment 2

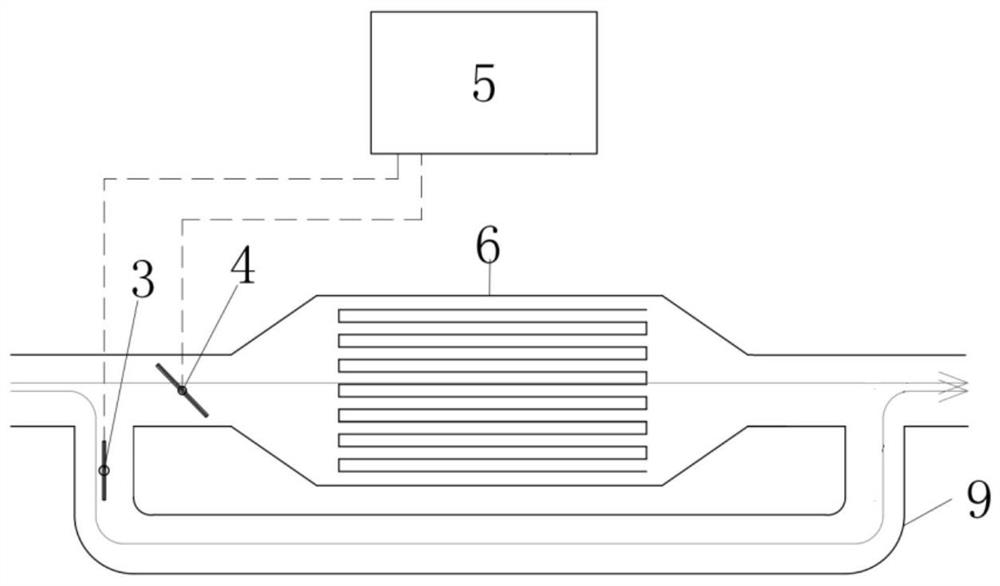

[0044] Embodiment 2. In this example, there are four solenoid valves, including solenoid valve one 3, solenoid valve two 4, solenoid valve three 7 and solenoid valve four 8. Solenoid valve one 3 and solenoid valve four 8 are respectively arranged in the bypass At both ends of the pipeline 9 , the solenoid valve 2 4 and the solenoid valve 3 7 are respectively arranged on the main pipeline 10 at the front end and the rear end of the particle trap 6 . The controller is an electronic controller 5 . Two solenoid valves are respectively arranged on the bypass pipeline 9 and the main pipeline 10, which can ensure the stability of the control.

[0045] The electronic controller 5 judges according to the central model temperature and model carbon amount of the particle trap in the controller algorithm, such as judging that there is no risk of burning the particle trap when the engine is cut off, and the accumulated carbon amount of the particle trap 6 is a safe carbon amount , it ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com