Plate heat exchanger

A technology of plate heat exchanger and heat exchange area, which is applied in the field of heat exchange, can solve the problems of uneven distribution of plate fluid, reduction of plate effective heat exchange area, and low utilization rate of plate surface, so as to improve uniformity , improve fluidity, improve the effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

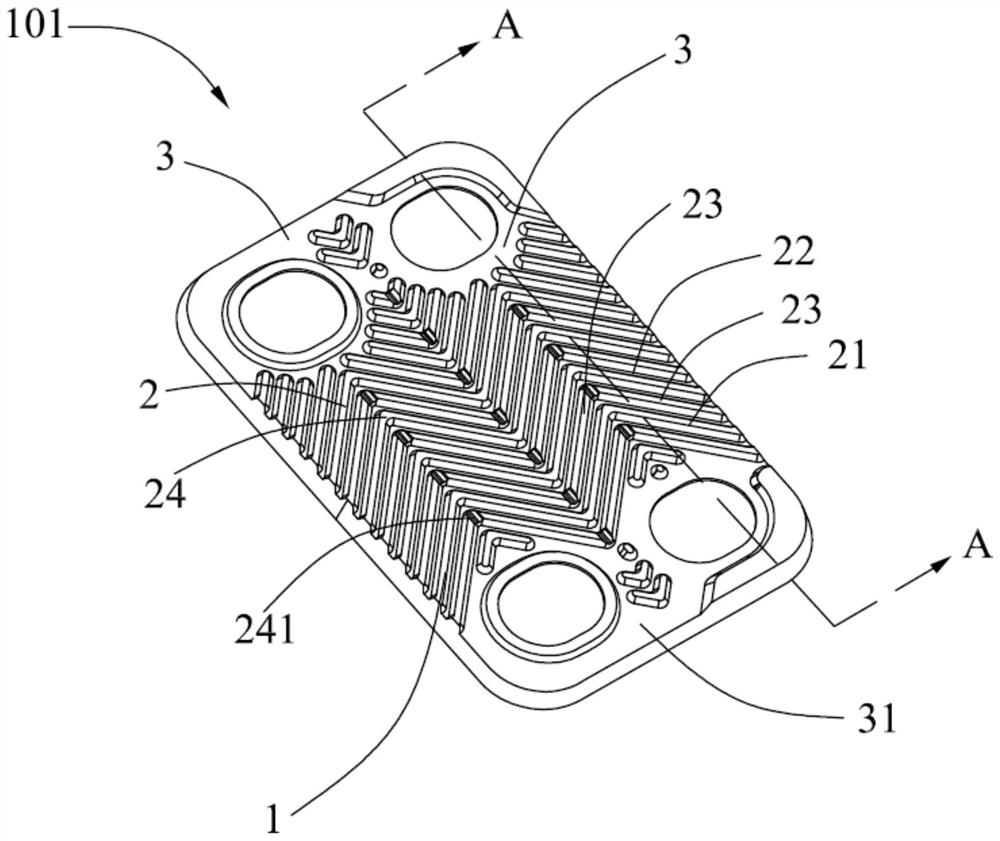

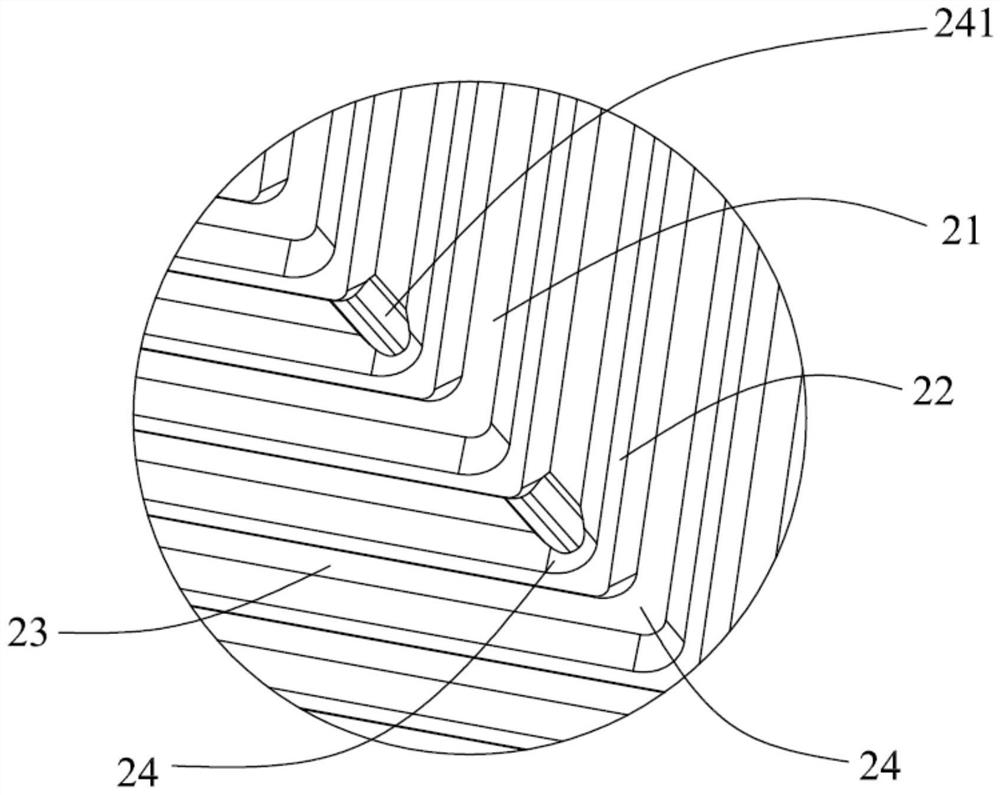

[0020] In the prior art, when the two plates of the plate heat exchanger are stacked together, there are generally large welding spots at the sharp corners of the herringbone wave pattern, resulting in the fluid flow at the sharp corners Less, or even no fluid passes through to form a flow dead zone, resulting in uneven flow distribution of the fluid on the plate, reducing the heat transfer performance of the plate heat exchanger. The plate heat exchanger provided by this application improves the channel structure formed by the corrugated structure on the plate, which is beneficial to reduce the difficulty of fluid distribution when the fluid flows near the curved part of the corrugated structure, and improves the uniformity of the fluid flowing on the plate, thereby improving the plate heat exchange. heat transfer performance of the device.

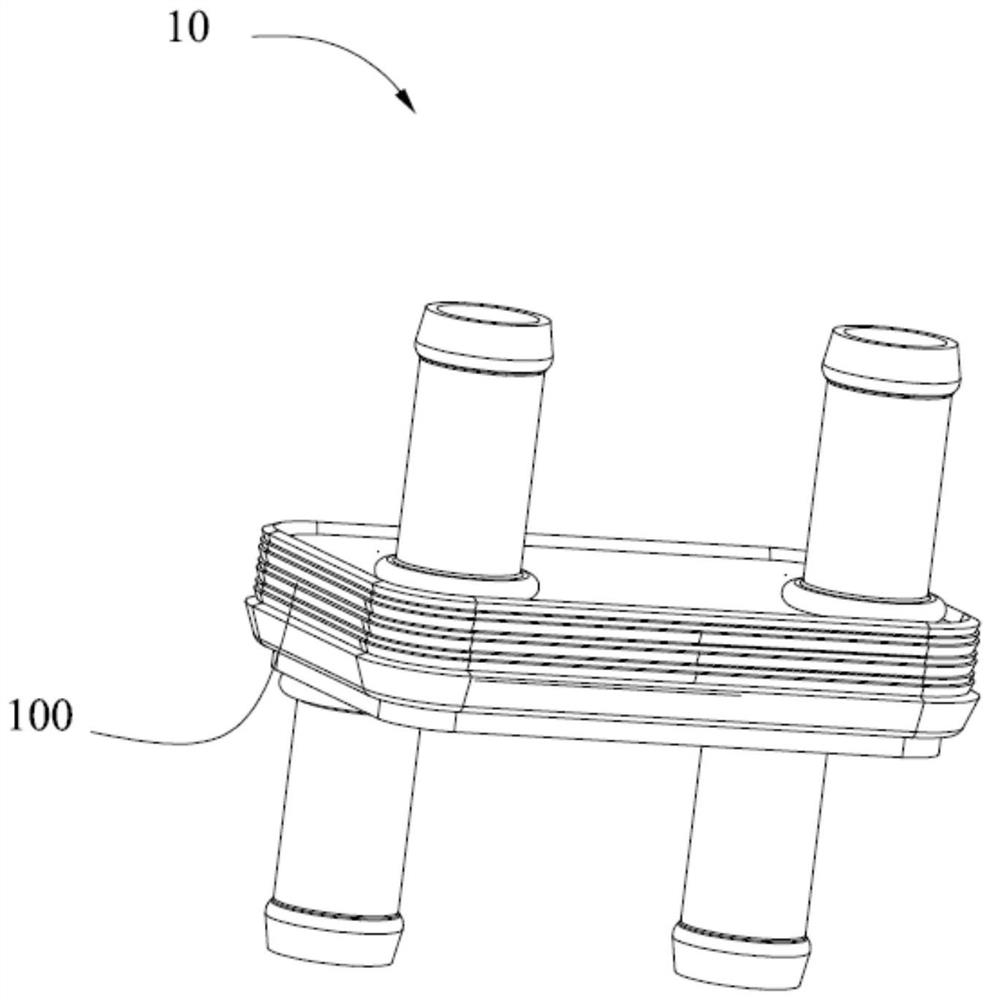

[0021] Such as Figure 1 to Figure 14 As shown, the embodiment of the present application provides a plate heat exchanger 10, includin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com