Testing fixture for auxiliary instrument panel of automobile

A technology for sub-dashboards and automobiles, which is applied in the direction of instruments, optical testing flaws/defects, and measuring devices. It can solve problems such as cumbersome tools, difficult automation, and complex inspection tools, and achieve high intelligence, improve efficiency, and improve work. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

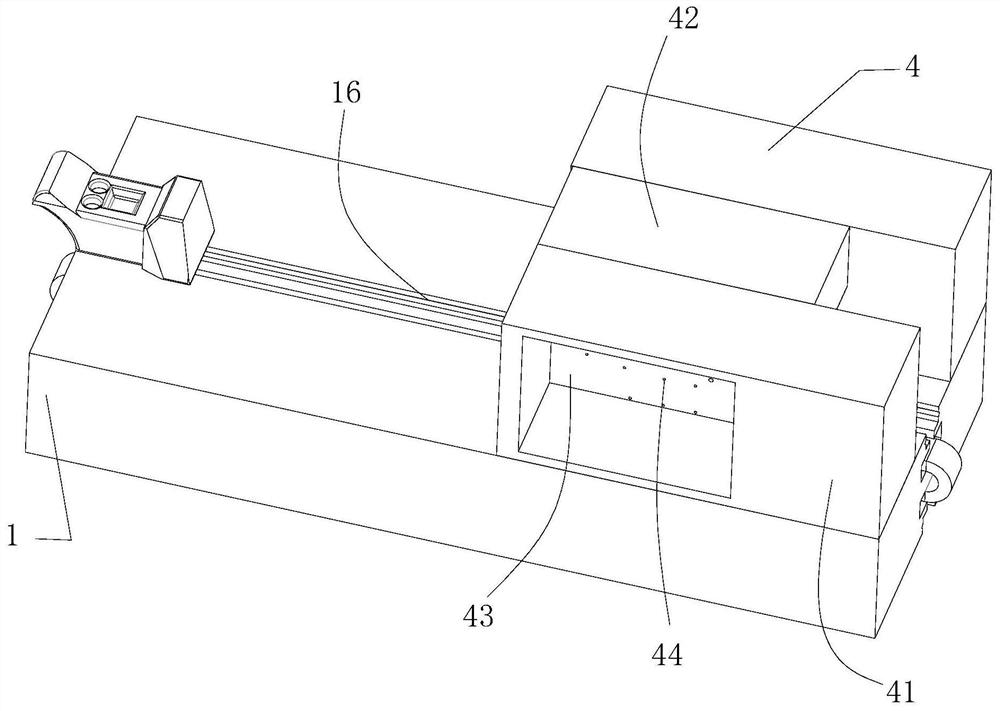

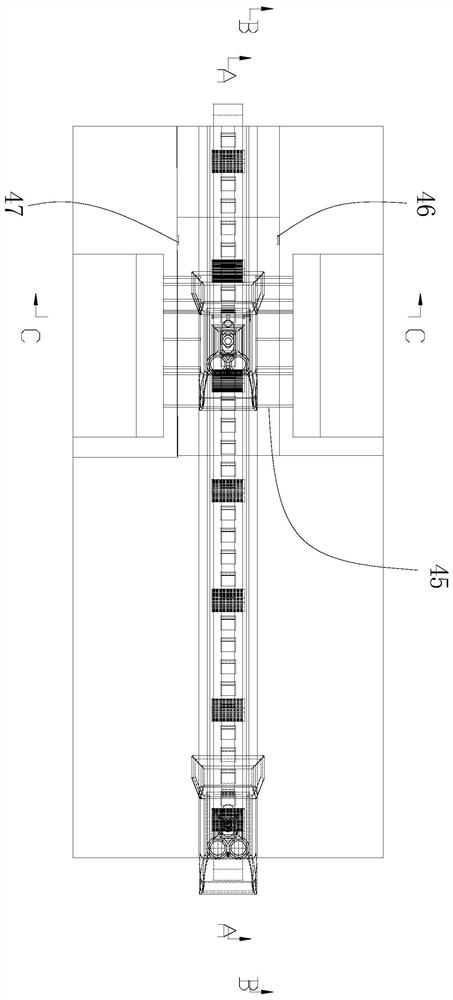

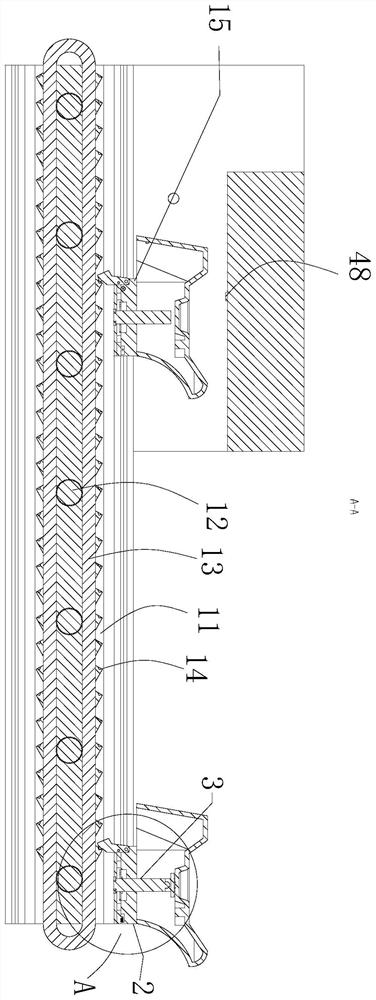

[0021] Such as Figure 1-11 As shown, a vehicle sub-dashboard inspection tool includes a distribution platform 1, a chain plate warehouse 11, a conveying roller 12, a conveying chain plate 13, a driving block 14, a connecting warehouse 15, a linear slide rail 16, an intermittent distribution device 2, a preliminary Clamping device 3, detection center 4, parking device 5; described chain board storehouse 11 is arranged in described distributing platform 1; Described conveying roller 12 is rotatably connected with described distributing platform 1; Described conveying chain plate 13 can be Rotationally connected to the connecting plate warehouse; the driving block 14 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com