Bolt pre-tightening force monitoring system

A bolt pre-tightening, monitoring system technology, applied in the signal transmission system, measuring torque/torsion force, force/torque/work measuring instrument and other directions during tightening, to achieve the effect of easy processing, wide application scenarios and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to better understand the contents of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

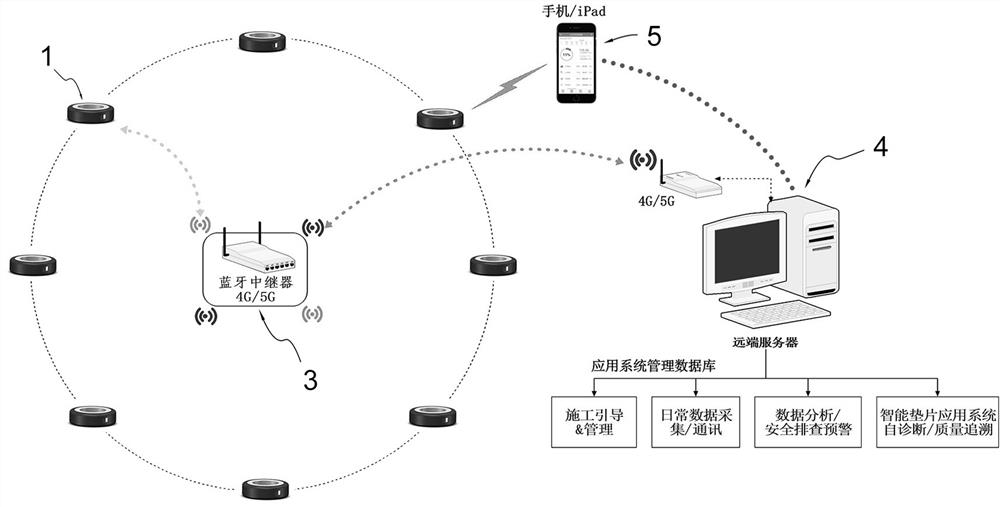

[0063] refer to figure 1 , the bolt pretightening force monitoring system shown in this example is the case where no on-site monitoring center is set up. The system includes an intelligent gasket sensor 1 , a Bluetooth repeater 3 , a remote server 4 and a mobile terminal 5 .

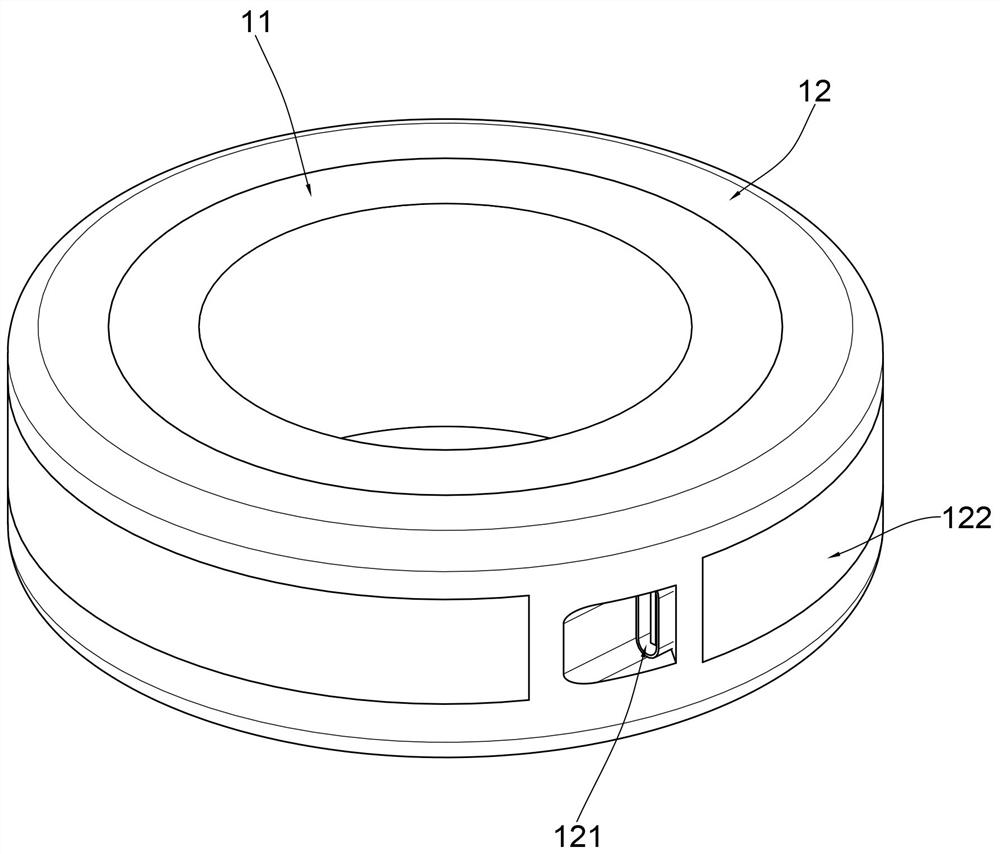

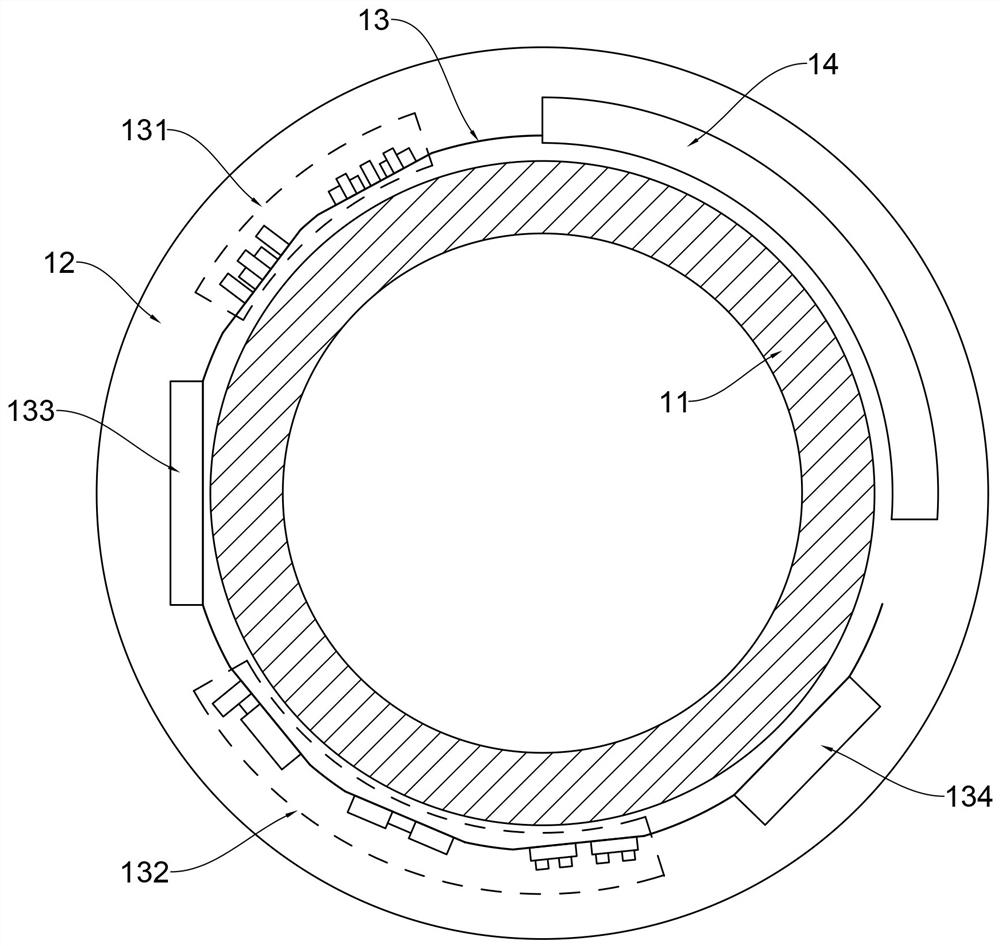

[0064] refer to figure 2 and image 3 , the smart pad sensor 1 of the present invention includes an elastic tube cylinder 11 , a rubber ring 12 , a strain gauge, a flexible circuit board 13 , a power storage module 14 and a solar film 122 . The middle of the elastic tube body 11 is a through hole matched with the bolt, and the rubber ring 12 is sleeved on the elastic tube body 11 . The strain gauges are attached to the outer surface of the elastic tube cylinder along the axial direction, and form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com