Device and method for measuring heated migration components of cigarette filter rod by adopting dynamic headspace method

A technology of dynamic headspace and additives, which is applied in the field of cigarette chemical detection, can solve problems such as the difficulty of accurate analysis of target objects, and achieve the effects of simple structure, accurate test results, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

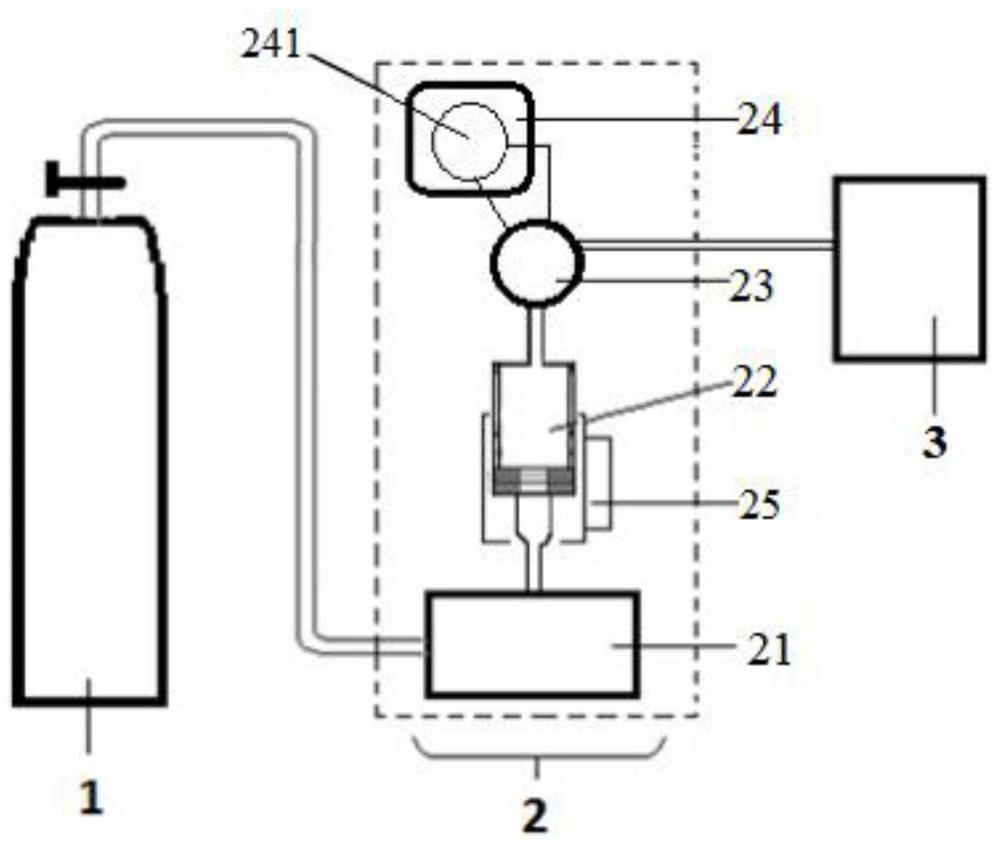

[0040] like figure 1 The device for determining the thermally migrated components of a cigarette filter rod by the dynamic headspace method includes: an air cylinder 1, a dynamic headspace instrument 2, and a gas chromatography / mass spectrometer 3; the dynamic headspace instrument 2 includes gas flow rate / Pressure control module 21, purge pipe 22, six-way valve 23 and adsorption / desorption module 24; the gas flow / pressure control module 21 is communicated with the inlet of the purge pipe 22, and the outlet of the purge pipe 22 It is connected to one valve port of the six-way valve 23; the gas chromatograph / mass spectrometer 3 is connected to two valve ports of the six-way valve 23. There is a heating module 25 on the periphery of the purging pipe 22; the adsorption / desorption module 24 contains a trap 241, and the trap material is tenax.

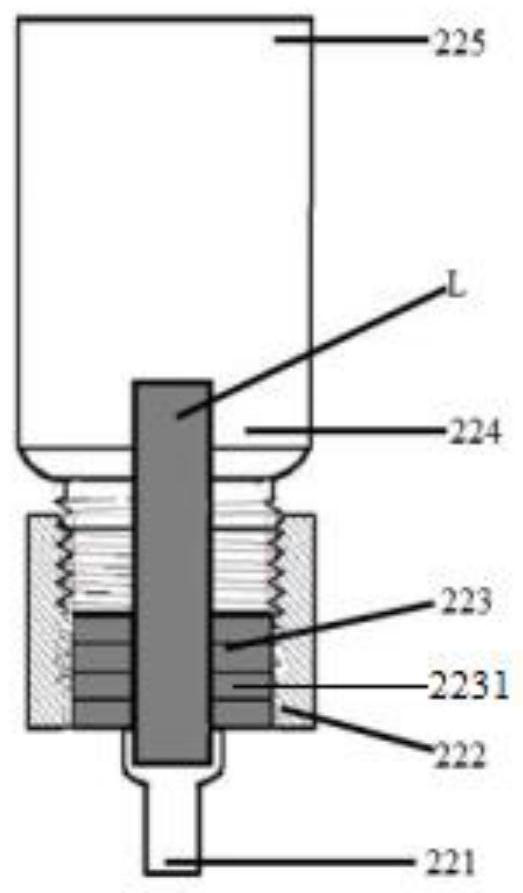

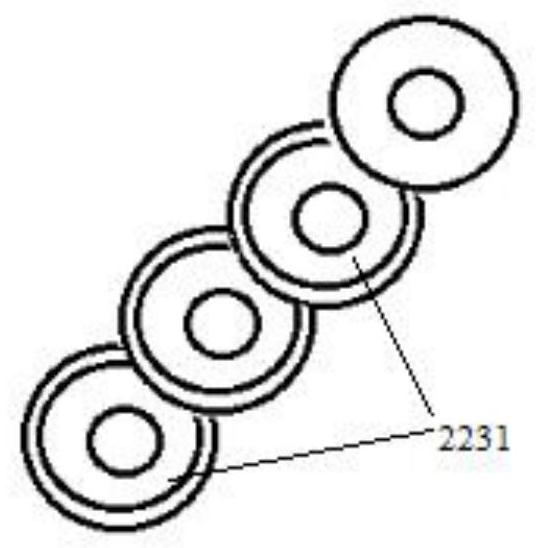

[0041] like figure 2 As shown, the purging pipe 22 includes a base 222 and a tube body 224; the lower port of the base 222 is an air i...

Embodiment 2

[0054] The test sample is cigarette filter stick sample B containing composite particles, and the device and test conditions are the same as in Example 1. The test results are shown in Table 2.

[0055] Table 2 Analysis results of thermal migration components in cigarette filter rod sample B containing composite particles

[0056]

[0057]

[0058] Note: a Represents the relative percentage content obtained by the peak area normalization method.

Embodiment 3

[0060] The test sample is cigarette filter stick sample C containing incense thread, and the device and test conditions are the same as in Example 1. It was found that the main thermally migrated components were menthol and menthyl acetate. Two standard substances, menthol and menthyl acetate, were used to prepare a standard working solution, and a standard curve was drawn to quantitatively analyze the thermal migration components. The results showed that the migration amounts of menthol and menthyl acetate were 0.073mg / cartridge and 0.033mg / cartridge respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionization energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap