A method for detecting coal seam roof-floor interface using borehole radar in underground coal mine

A technology of drilling radar and bottom plate, which is applied in the fields of electromagnetic wave detection, electric/magnetic detection for well logging records, and re-radiation, and can solve the problem of poor coal mine working face environment, complex geological conditions, and poor engineering applications etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

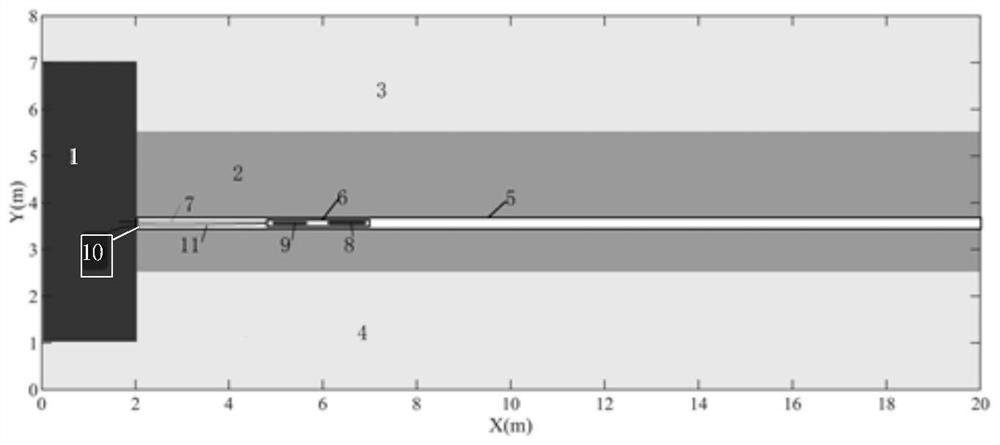

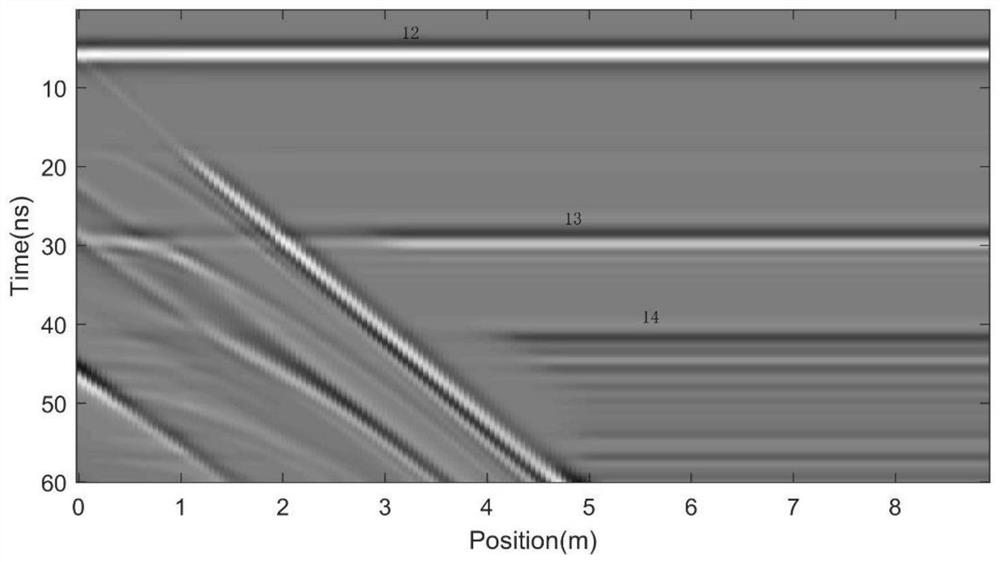

[0065] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0066] The harsh environment and complex geological conditions of the coal mine working face make the existing coal rock identification methods poor in adaptability and identification accuracy, and have not been well applied in engineering. In actual production, it is still relying on the driver of the shearer to manually adjust the height of the shearer drum to cut the top and bottom through visual and auditory judgment. The adjustment accuracy is low and the labor intensity is high.

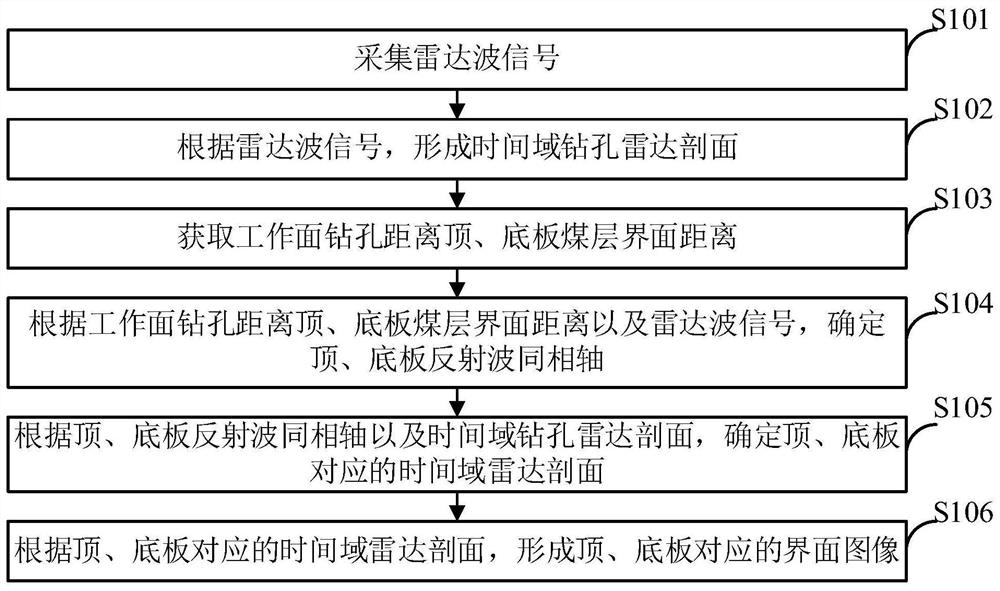

[0067] The invention provides a method for detecting the roof-bottom interface of a coal seam by using a borehole radar in a coal mine. According to the radar wave signal, a time-domain borehole radar profile is formed. , the time-domain radar profile corresponding to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com