Server assembly integrated management system for different component factories

A management system and management method technology, applied in the field of server assembly management, can solve the problems of data query, low management efficiency, etc., and achieve the effect of improving the level of integrated management, ensuring the accuracy, and improving the efficiency of data query.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

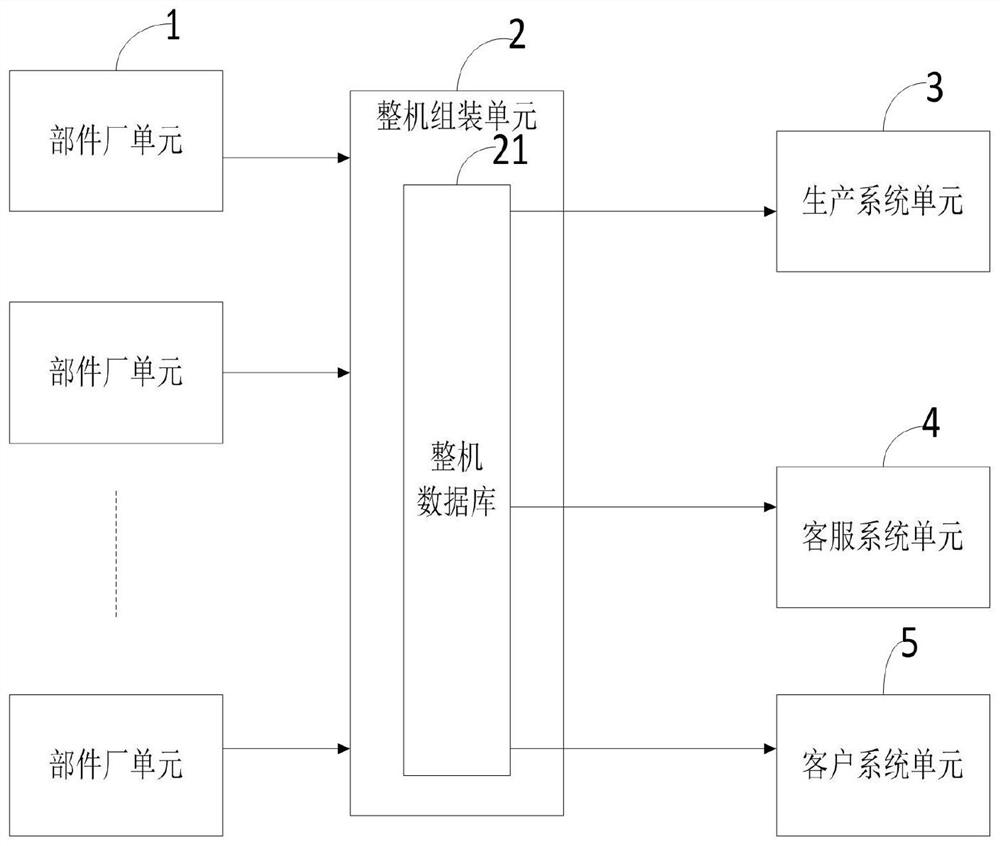

[0031] Such as figure 1 As shown, the present invention provides an integrated server assembly management system for different parts factories, including: a plurality of parts factory units 1, a complete machine assembly unit 2, a production system unit 3, a customer service system unit 4, and a customer system unit 5, Each component factory unit 1 communicates with the complete machine assembly unit 2, and actively sends the component information of each component in the component factory unit 1 to the complete machine assembly unit 2; For all component information, establish a complete machine database 21, store all information of each component in the complete machine database 21, and return corresponding components according to the corresponding authority of the production system unit 3, customer service system unit 4, and customer system unit 5 Information data; the production system unit 3, the customer service system unit 4, and the customer system unit 5 are all commun...

Embodiment 2

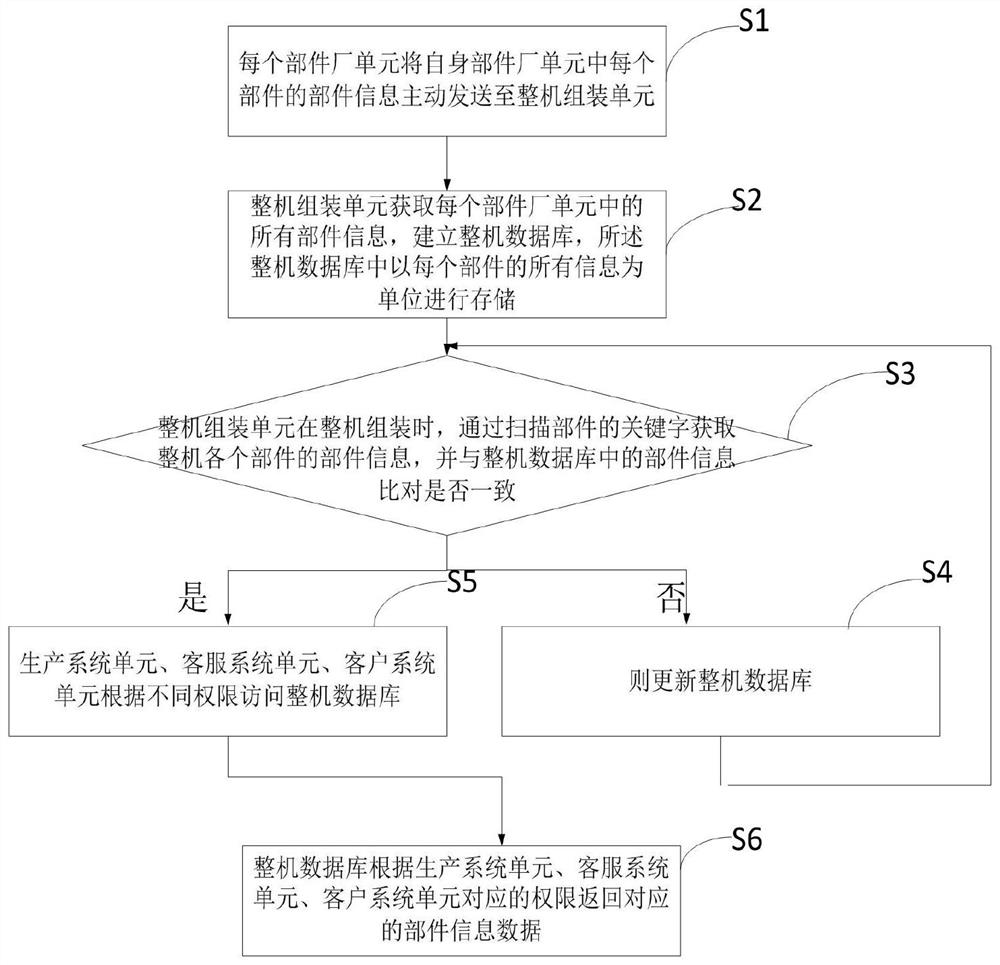

[0043] Such as figure 2 As shown, the technical solution of the present invention also provides an integrated management method for server assembly of different parts factories, which is implemented on the basis of Embodiment 1, including:

[0044] S1, each component factory unit actively sends the component information of each component in its own component factory unit to the whole machine assembly unit;

[0045] S2, the complete machine assembly unit obtains all the component information in each component factory unit, and establishes a complete machine database, which stores all the information of each component in the complete machine database;

[0046] S3. When assembling the whole machine, the whole machine assembly unit obtains the part information of each part of the whole machine by scanning the keywords of the parts, and compares whether it is consistent with the part information in the whole machine database. If the comparison result is no, execute Step S4; if th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com