Fixing structure of PCBA board

A fixed structure, one-to-one correspondence technology, applied to the circuit layout, elastic/clamping device and other directions on the support structure, can solve the problems of electrical function influence, solder cracks of components, etc., to achieve firm fixation and avoid tin cracks , the effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

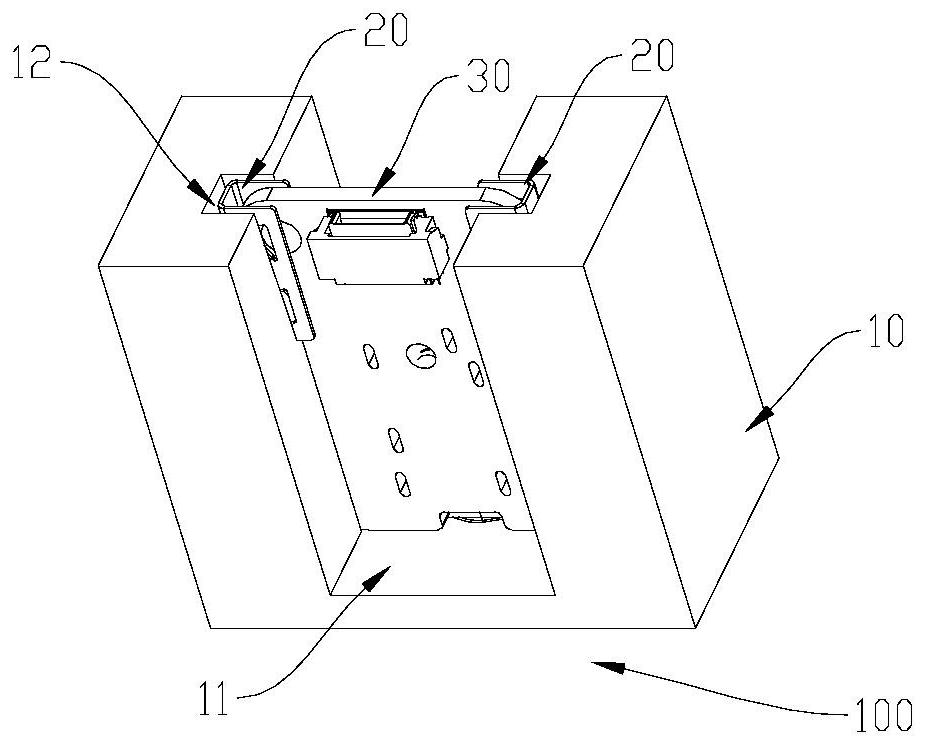

[0040] Please also refer to Figure 1 to Figure 3 , this embodiment provides a fixed structure 100 applied to the PCBA board 30, the structure of the fixed structure 100 is simple, easy to assemble, can reduce the stress on components during assembly, avoid stress concentration, and can also avoid tin cracks phenomenon, and has good applicability.

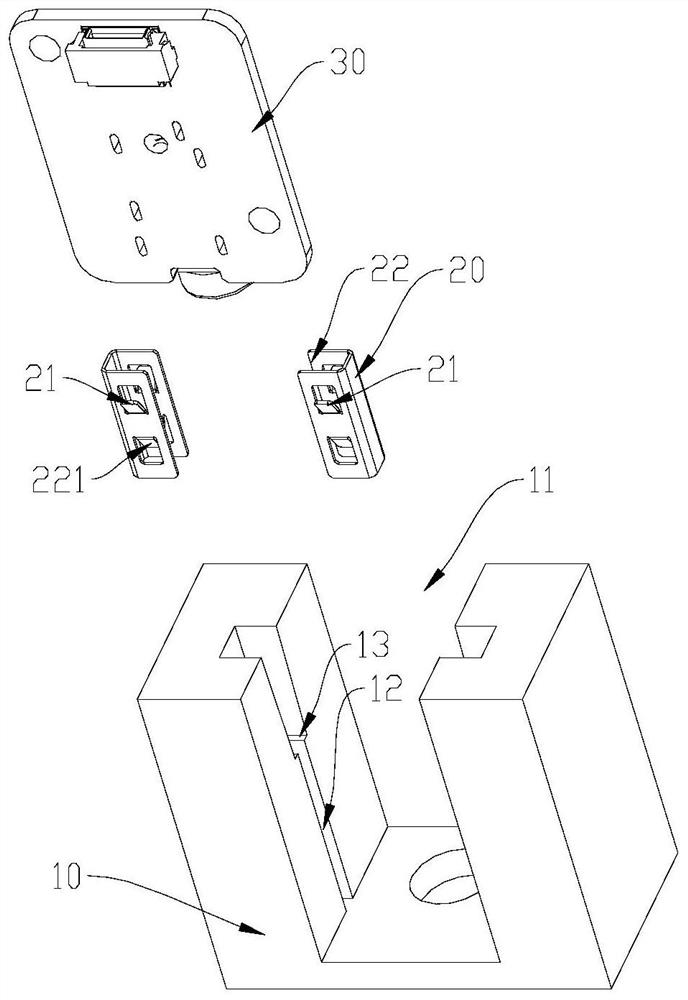

[0041] The fixing structure 100 at least includes: a structural body 10 and at least one pair of elastic members 20, a notch 11 is formed on the structural body 10, and the notch 11 is arranged in a U-shape, and the opposite sides of the notch 11 are correspondingly provided with installation grooves 12 , the PCBA board 30 can be vertically inserted and fixed on the structural body 10 along the installation groove 12 ; Wherein, the side of the elastic member 20 facing the side of the installation groove 12 is formed with a barb portion 21, the barb portion 21 can be embedded and fixed at the side wall position of the installation ...

Embodiment 2

[0047] The difference with the first embodiment above is that:

[0048] Please also refer to Figure 4 to Figure 6 In order to better fix the PCBA board 30 vertically inserted into the installation groove 12 based on the pressing part 221, a limited opening 31 is formed on the layer of the PCBA board 30 facing the installation groove 12, and each pressing part 221 can penetrate into the limiting opening 31 , so that each pressing portion 221 can be locked against the limiting opening 31 , thereby achieving the effect of preventing the PCBA board 30 from falling out of the mounting groove 12 .

Embodiment 3

[0050] The difference with the above-mentioned second embodiment is:

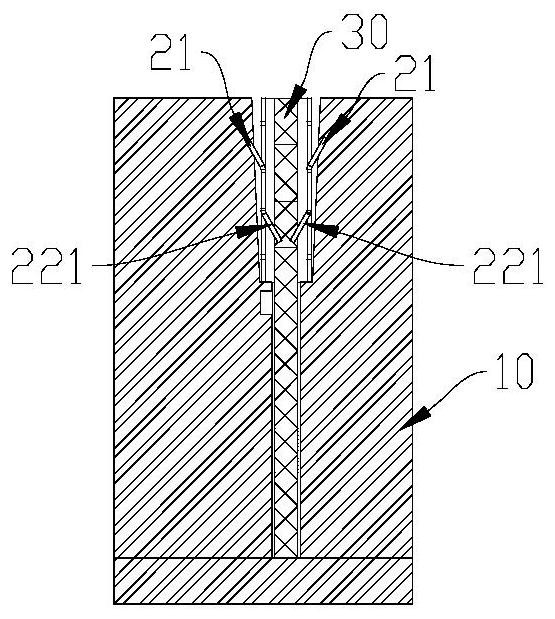

[0051] Please also refer to Figure 7 to Figure 10 The elastic member 20 provided in this embodiment is formed with a guide groove 22, and the end portions of the two side walls of the guide groove 22 facing the bottom surface of the notch 11 are formed with pressing portions 221, and each pressing portion 221 is at least partially movably overlapped. It can be understood that when the PCBA board 30 is not inserted into the guide groove 22, at least part of the two pressing parts 221 overlap each other, as Figure 9 As shown; when the PCBA board 30 is gradually inserted along the guide groove 22, the two pressing parts 221 can be separated from each other under the promotion of the PCBA board 30, until the two pressing parts 221 and the limit opening on the PCBA board 30 After that, the two pressing parts 221 penetrate into the limiting opening 31 and the two pressing parts 221 return to a partially overla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com