Electrical wire exterior body and wire harness equipped with exterior body

A kind of wire and sheath technology, applied in the field of wire sheath and wire harness with sheath

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

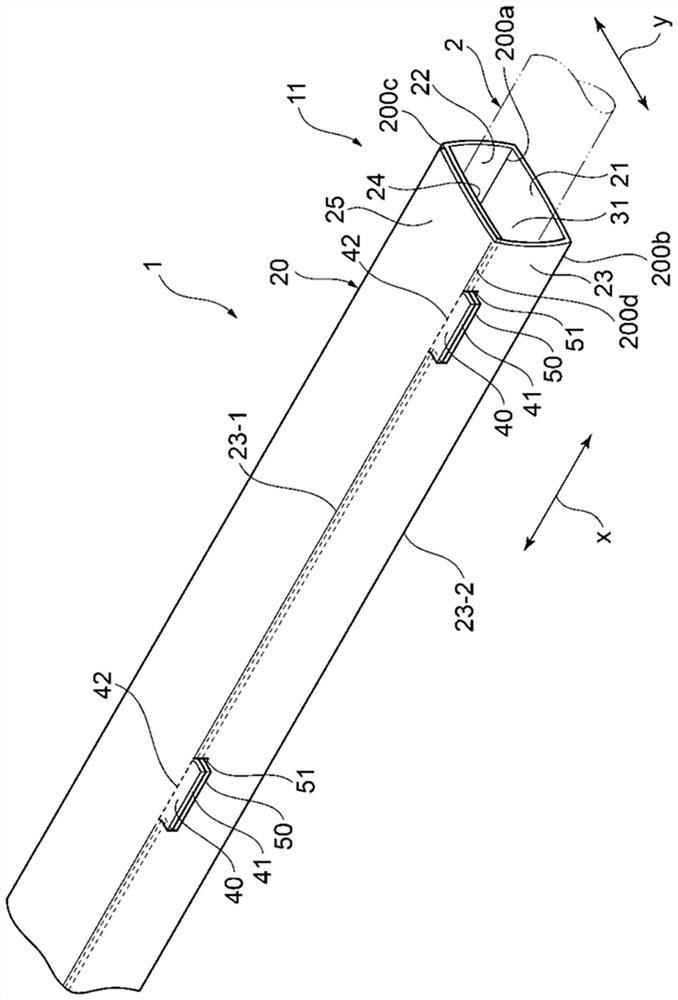

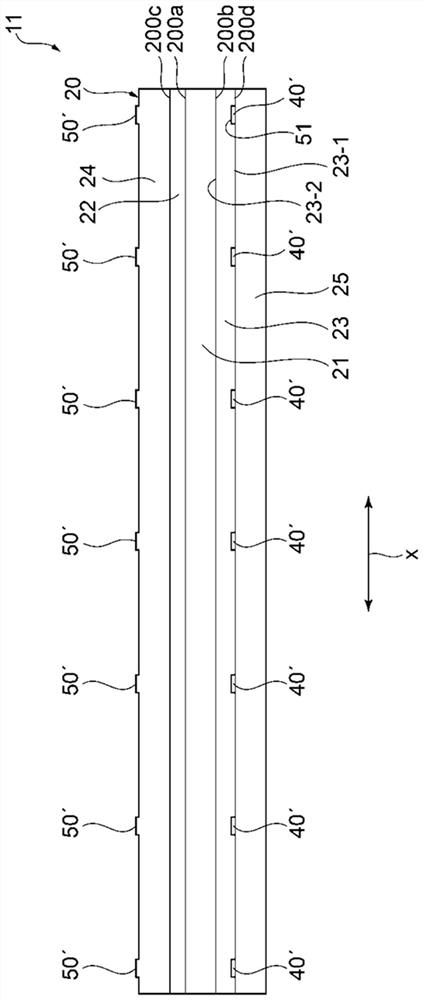

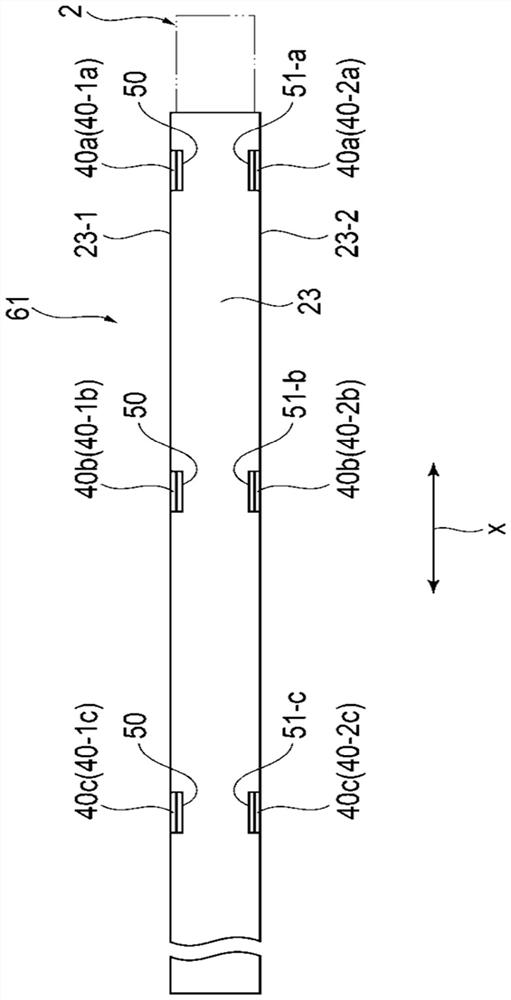

[0038] Hereinafter, the sheath for electric wires which concerns on embodiment of this invention is demonstrated in detail using drawings. It should be noted, figure 1 It is a perspective view explaining the outline|summary of the sheath for electric wires of 1st Embodiment of this invention, and the wire harness with a sheath. figure 2 It is an explanatory drawing which shows the state which expanded the electric wire sheath of 1st Embodiment. image 3 It is a side view explaining the outline|summary of the sheath for electric wires of 2nd Embodiment of this invention, and the wire harness with a sheath. Figure 4 It is a side view explaining the outline|summary of the sheath for electric wires of 3rd Embodiment of this invention, and the wire harness with a sheath. Figure 5 (a) to (c) are explanatory diagrams each showing the shape of the protruding portion of the sheath for an electric wire according to another embodiment of the present invention. Image 6 It is an exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com