Genetically engineered bacterium for producing L-methionine at high yield as well as construction and application of genetically engineered bacterium

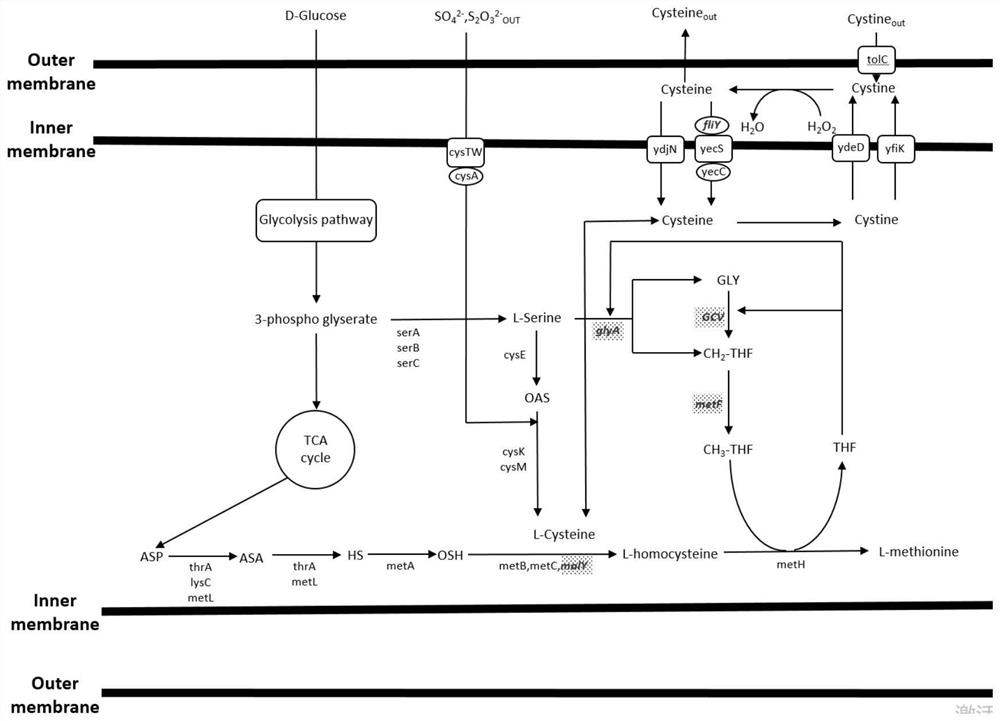

A technology of genetically engineered bacteria and methionine, applied to genetically engineered bacteria with high production of L-methionine and its construction and application fields, can solve the problems of methionine dependence on imports, limited methionine production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Fermentation method and content determination of L-methionine high-yielding strain

[0051] The fermentation method is as follows:

[0052] The constructed strain was inoculated into 10 mL of LB medium containing 50 mg / L of Kan, and after 8-12 h, the genetically engineered bacterial strain was transferred to 20 mL of MS fermentation medium containing Kan, and CaCO was added during inoculation. 3 0.3g / L, VB 12 The mother liquor was 20 μl / mL, the lysine mother liquor was 20 μl / mL, and the fermentation was carried out at 28° C. and 180 rpm until 48 hours.

[0053] The MS fermentation medium is composed as follows: glucose 20g / L, (NH 4 ) 2 SO 4 16g / L, KH 2 PO 4 1g / L, Na 2 S 2 o 3 2g / L, yeast extract 2g / L, 1ml / L trace element solution, the solvent is deionized water, the pH value is natural; the composition of trace element solution is: 500g / L MgSO 4 ·7H 2 0,5g / L FeSO 4 ·7H 2 O, 5g / L MnSO 4 ·8H 2 0,5g / L ZnSO 4 , the solvent is deionized water. ...

Embodiment 2

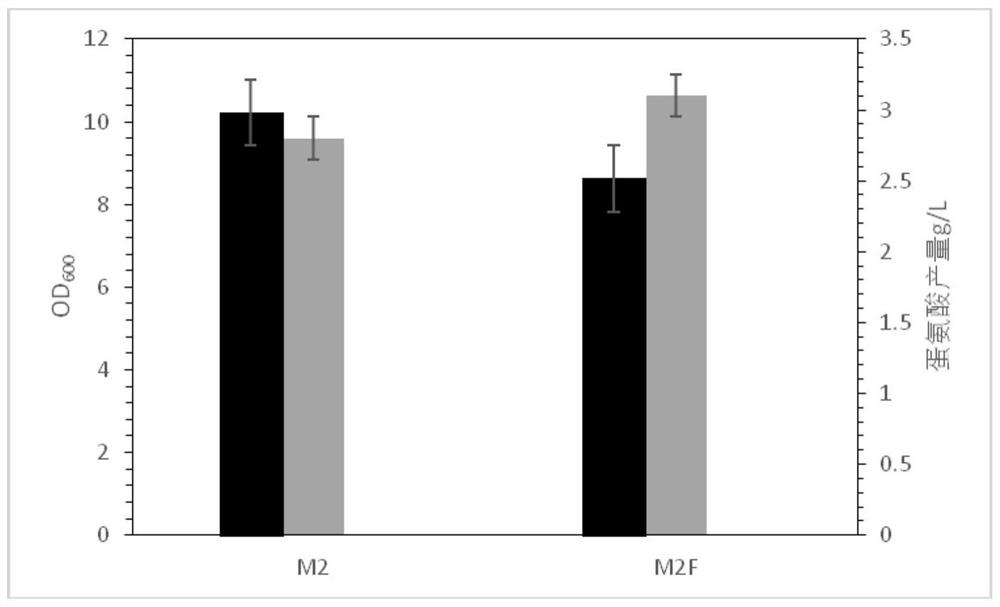

[0058] Embodiment 2: Construction of effective bacterial strain E.coli W3110 M2 / pAm metF and its shake flask fermentation

[0059] (1) Construct the pAm metF plasmid: use the previously constructed pAm plasmid (see the plasmid map Figure 7 ) as a template, using pAm-line-F / pAm-line-R as primers to obtain the PCR linear amplification product pAm-line plasmid, the PCR product was digested by DpnI at 37°C for 3 hours, and then the DNA fragment was recovered with the Clean up kit; Using the genome of E.coli W3110 as a template and using pmetF-F / pmetF-R as primers to obtain the PCR amplification product metF, the DNA fragment was recovered by the Clean up kit; according to ClonExpress (One step clone kit, Vazyme Biotech, Nanjing, China) The instructions connect the linearized pAm-line plasmid and fragment metF together, and transform the ligated product into DH5α competent through chemical transformation; finally select the clones, and obtain the pAm metF plasmid through sequencin...

Embodiment 3

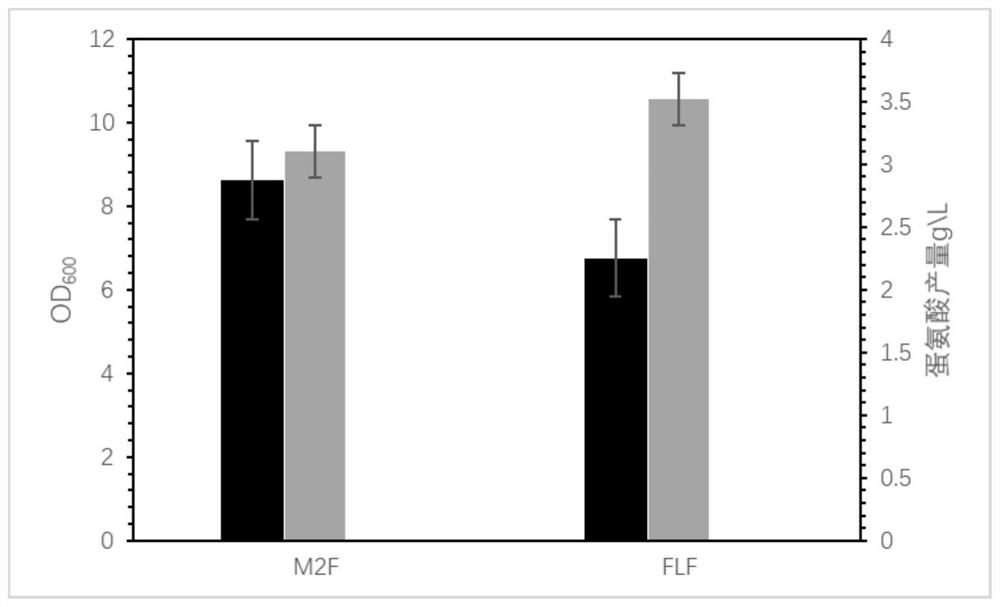

[0064] Embodiment 3: Construction effective bacterial strain E.coli W3110 M2(Trc-fliy) / pAm metF and shake flask fermentation thereof

[0065] Using Escherichia coli W3110 M2 / pAm metF as the starting strain, use CRISPR-Cas9-mediated gene editing technology (Yu Jiang et al.2015Multigene Editing in the Escherichia coliGenome via the CRISPR-Cas9 System.Applied Environmental Microbiology.81:2506-2514 ), replace the original promoter of fliY in the genome with the trc promoter derived from pTrc99A (the nucleotide sequence is shown in SEQ ID No.1), so as to enhance the expression intensity of fliY.

[0066] (1) Construction of pTarget-fliY plasmid: Use pTarget F plasmid (Addgene Plasmid#62226) as a template, use pT-fliY-F / pT-fliY-R as primers for PCR amplification, and the PCR product is digested by Dpn I at 37°C 3h, and then transformed into E.coli DH5α, screened on the spectacle enzyme plate, and sequenced to verify that the correct pTarget-fliY plasmid was obtained, which was used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com