Excavator forearm and excavator

A technology for excavators and booms, applied in the field of excavators, can solve the problems of high energy consumption, low energy utilization rate of excavators, lack of structure and technical solutions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

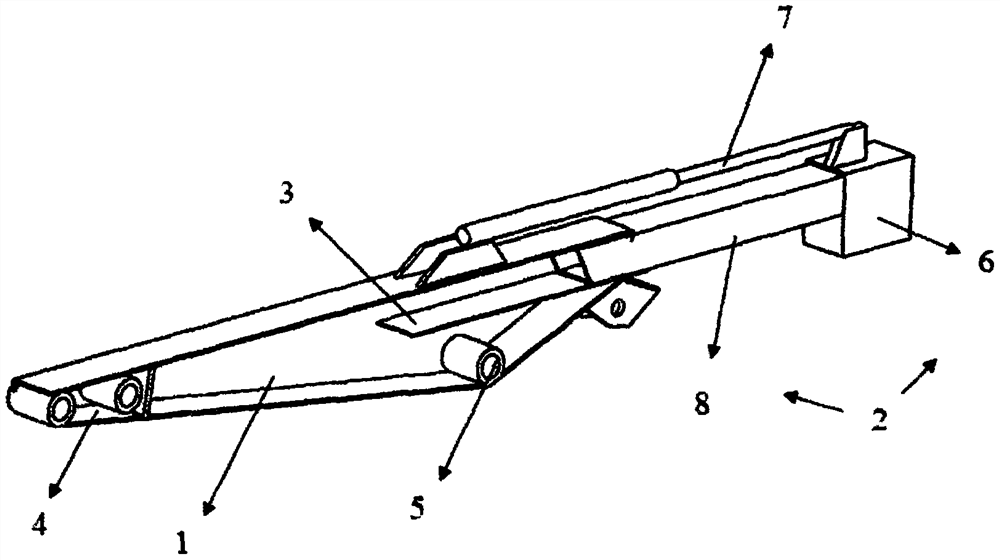

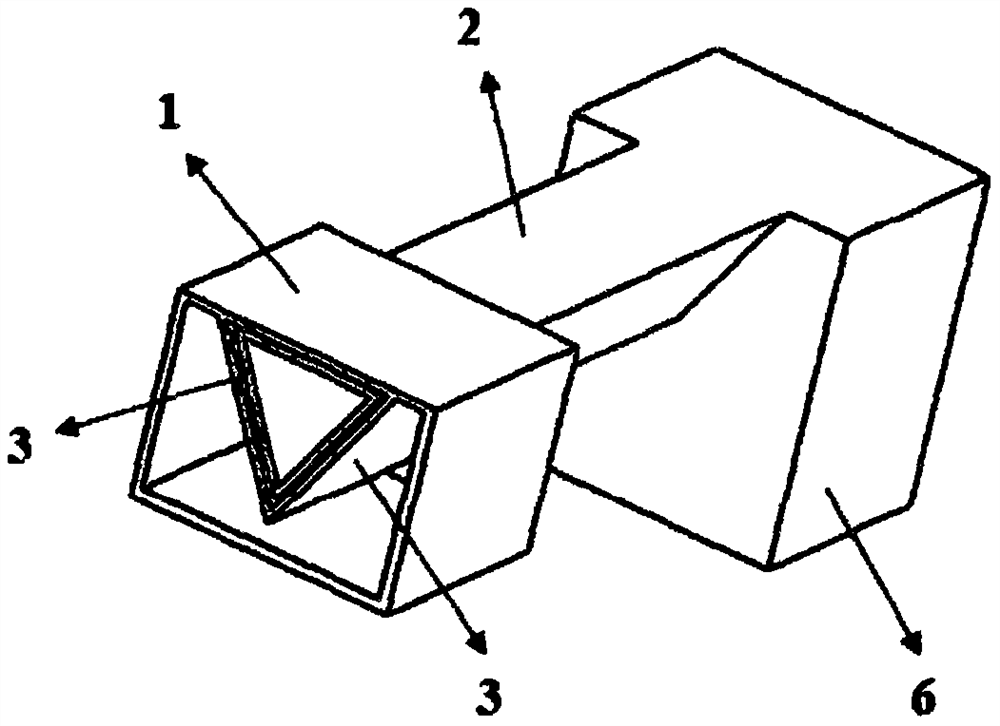

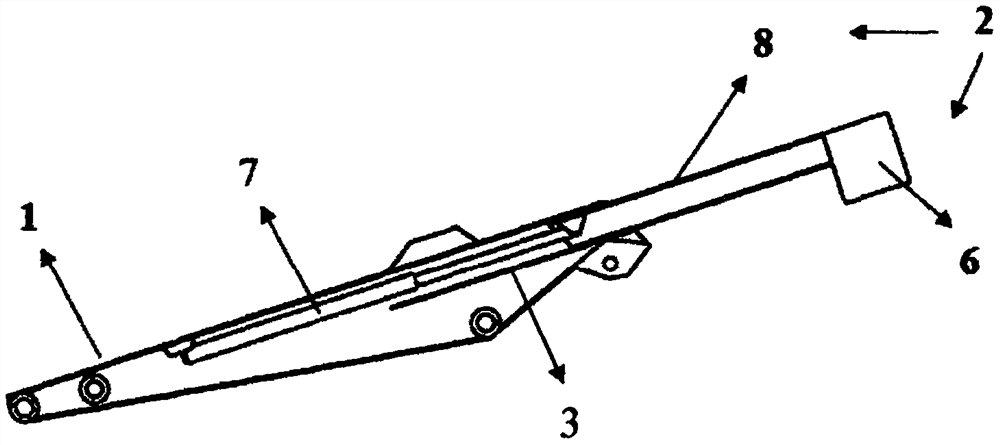

[0052] see figure 1 , figure 2 , image 3 , Figure 4 , a small arm of an excavator, including a forearm body 1, a rear arm body 2, a support plate 3 and a telescopic cylinder 7, the forearm body 1 includes a front end connecting portion 4 and a small arm spindle hole 5, and the front end connecting portion 4 is arranged on the forearm body 1 The front end of the front end, the front end connecting part 4 is used to connect the working device of the excavator, such as working devices such as buckets and extended sleeve arms, the forearm main shaft hole 5 is arranged on the front arm body 1 arm body behind the front end connecting part 4 position, and the forearm body 1 wraps around The forearm body 1 of the forearm of the forearm of the excavator is composed of high-strength plates such as the top plate, the middle side plate, and the bottom plate through welding to form a box structure with a cavity inside. When manufacturing the forearm body 1, The support plate 3 is wel...

Embodiment 2

[0055] see Figure 5 , the counterweight 6 includes a counterweight frame 6a and a counterweight 6b, the counterweight 6b includes a first counterweight 6b1 and a second counterweight 6b2, the counterweight frame 6a is an arm structure, and the tail of the rear arm 8 is connected to the counterweight In the middle of the frame 6a, one end of the counterweight frame 6a is connected to the first counterweight 6b1, and the other end of the counterweight frame 6a is connected to the second counterweight 6b2; because there are many working devices installed directly under the range of movement of the tail of the arm of the existing excavator , such as hydraulic pipelines, electrical circuits, oil cylinders, valve bodies, etc., the width of these devices after installation is close to the width of the forearm. This embodiment can prevent the counterweight 6 from touching these when the rear arm body 2 moves downward. device.

[0056] In this embodiment, the form of the counterweigh...

Embodiment 3

[0059] see Figure 7 , the counterweight frame 6a includes a first counterweight arm 6a1, a second counterweight arm 6a2 and a third counterweight arm 6a3, the counterweight 6b includes a first counterweight 6b1 and a second counterweight 6b2, and the tail of the rear arm 8 Connect the middle part of the first counterweight arm 6a1, one end of the first counterweight arm 6a1 is connected to the upper end of the second counterweight arm 6a2, the other end of the first counterweight arm 6a1 is connected to the upper end of the third counterweight arm 6a3, and the lower end of the second counterweight arm 6a2 is connected to The lower end of the first counterweight 6b1 and the third counterweight arm 6a3 is connected to the second counterweight 6b2. This structure moves the position of the counterweight down, lowering the overall center of gravity of the arm, thereby improving the symmetry between the power arm and the resistance arm , to further reduce the energy consumption of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com