Reed switch contact gap adjusting device

A contact gap and adjustment device technology, applied in the field of reed switches, can solve the problems of low market share, slow speed, uneven production technology and process, etc., achieve uniform and accurate gaps, speed up production efficiency, fine processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

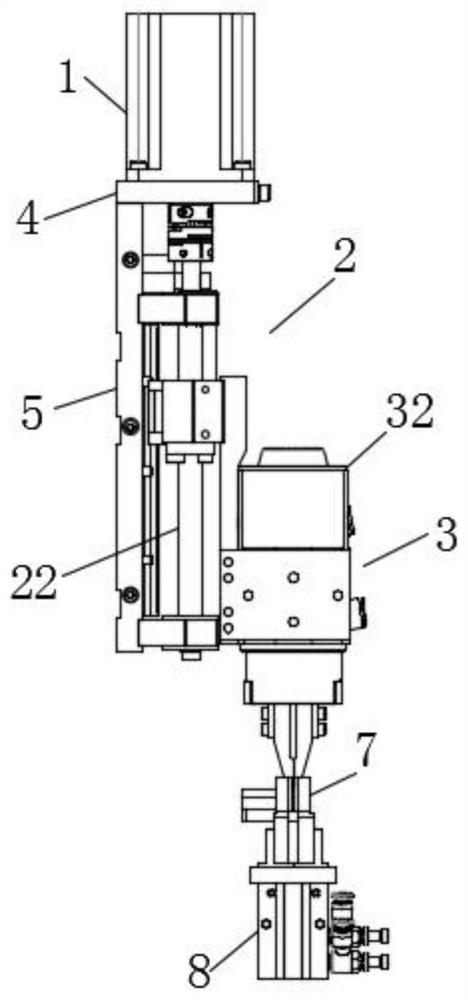

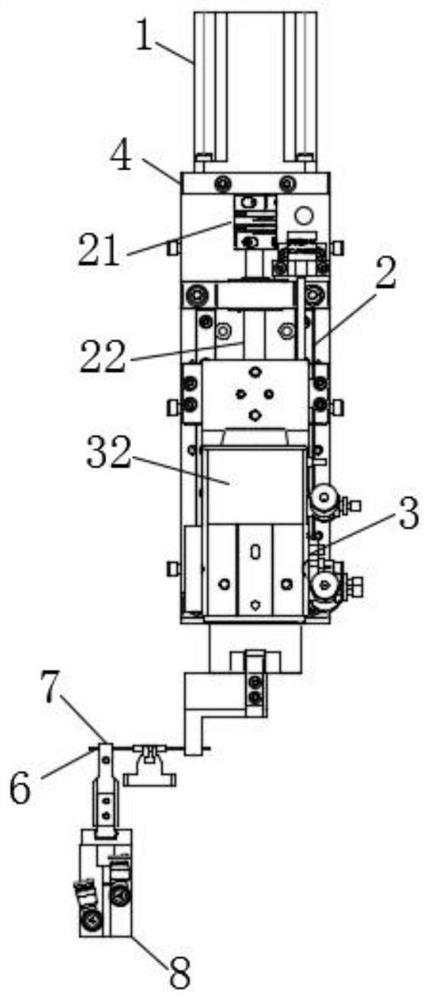

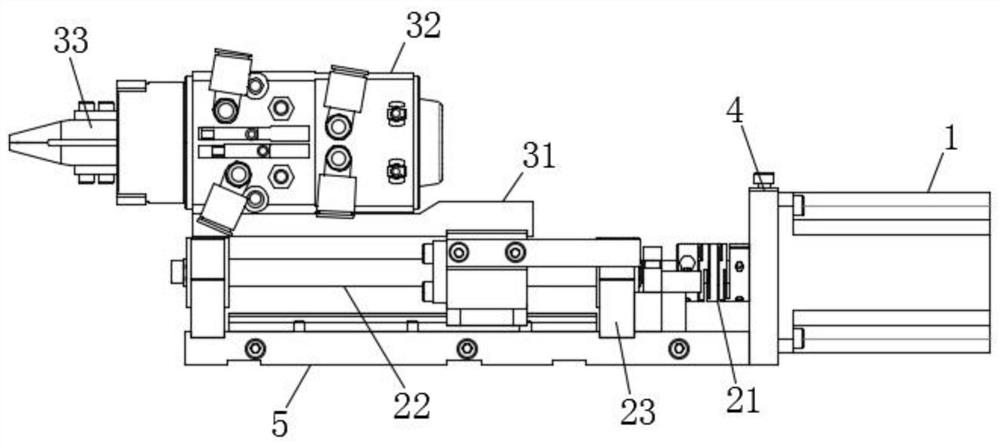

[0023] Example: such as Figure 1-8 As shown, the reed switch contact gap adjustment device of the present invention includes a stepping motor 1, the lower end of the stepping motor 1 is fixedly connected to a motor fixing plate 4, and the motor fixing plate 4 provided is used for fixing and fixing the stepping motor 1. protection, to facilitate the use of the stepper motor 1, the lower end of the motor fixing plate 4 is fixedly connected to the upper and lower mechanism fixing plate 5, and the upper and lower mechanism fixing plate 5 provided can support and fix the upper and lower motor mechanism 2 on the pin line. The output end of the motor 1 passes through the motor fixing plate 4 and is equipped with an up and down electric mechanism 2 on the pin line. The set up and down electric mechanism 2 on the pin line can facilitate the movement of the pin line clamping pneumatic mechanism 3, thereby facilitating the driving of the pin line 6 Move, the pin line clamping pneumatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com