Electroplating environment air circulation system

A circulation system and ambient air technology, applied in the field of air purification, can solve the problems of poor air quality, troubles, and inability to suction waste waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

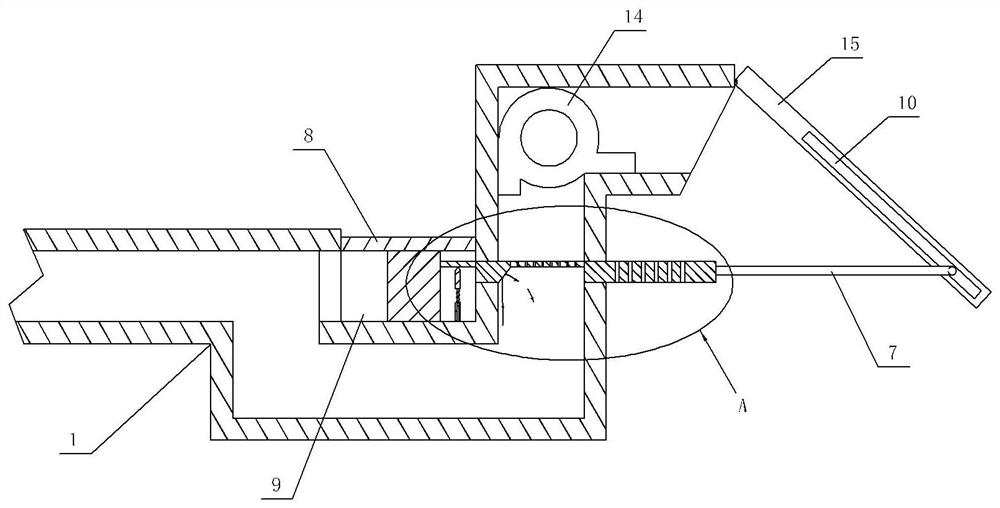

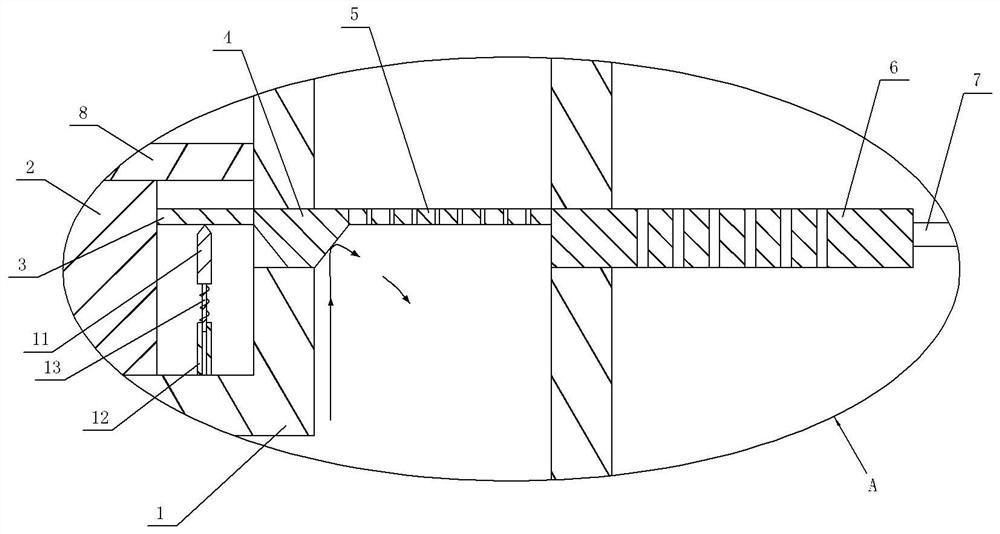

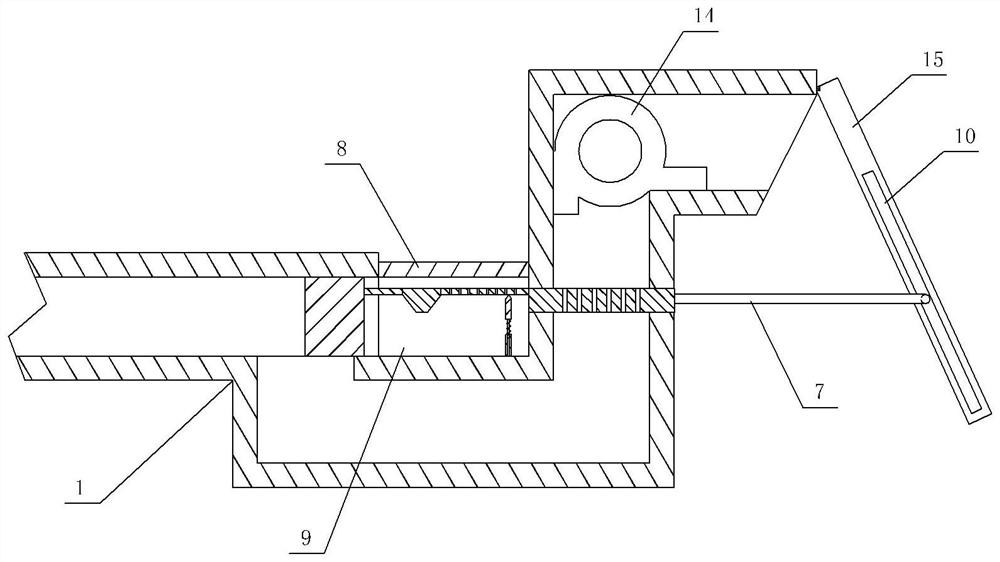

[0021] The embodiment is basically as attached Figure 1-3 Shown: as figure 1 The air circulation system of electroplating environment shown includes suction pipe 1, push block 2, connecting strip 3, trapezoidal strip 4, filter screen 5, filter plate 6, L-shaped rod 7, shielding frame 8 and cleaning mechanism; suction pipe 1 is bent, the suction pipe 1 includes a first horizontal pipe, a vertical lower pipe, a second horizontal pipe, a vertical upper pipe and a third horizontal pipe, each component of the suction pipe 1 is in the shape of a cuboid, and the shielding frame 8 and The vertical lower pipe, the second horizontal pipe and the vertical upper pipe form a closed space 9, and the right end of the suction pipe 1 is connected with a baffle plate 15 through pin rotation, and the left end of the suction pipe 1 is positioned at the grinding table.

[0022] like figure 2 As shown, the push block 2, the connecting bar 3, the trapezoidal bar 4, the filter screen 5, the filte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap