Method for ensuring rigidity of ring piece in rolling process of rectangular ring piece

A rectangular ring, rolling process technology, applied in the direction of metal rolling, etc., can solve the problem of not being able to ensure the rigidity of the ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

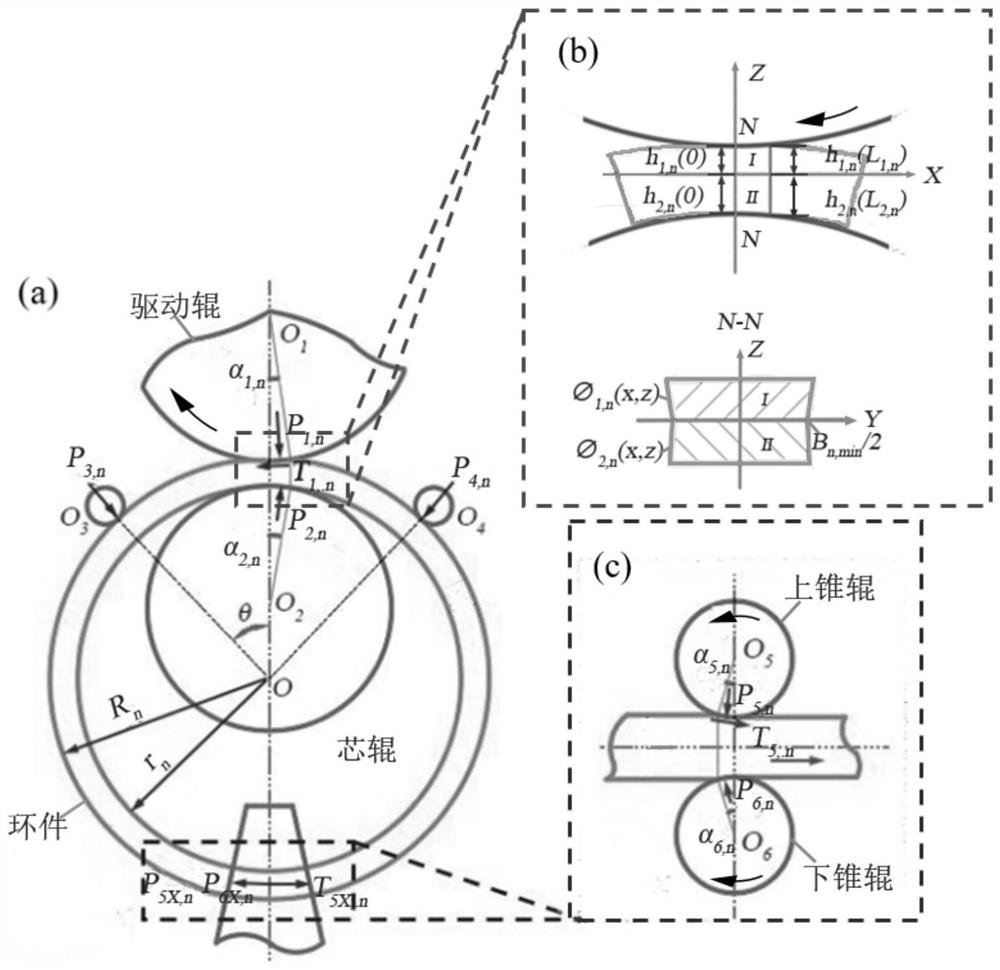

[0112] This embodiment discloses a method for ensuring the rigidity of a rectangular ring during the rolling process. The rolling equipment adopts a horizontal ring rolling machine, which includes the following steps:

[0113] 1) Determine the radial rolling process parameters of the ring. Among them, the radial rolling process parameters of the ring include the initial outer diameter of the ring blank D 0 , the initial inner diameter of the ring blank d 0 , the initial wall thickness H of the ring blank 0 , core roll radial feed rate v(t), material shear yield strength k, ring and roll friction coefficient μ, material yield stress σ s , the friction factor m between the ring and the roll, the apex angle γ of the tapered roll, the angle θ between the guide roll and the z-axis, and the radius R of the tapered roll corresponding to the contact between the tapered roll and the outer surface of the ring 6 , the linear velocity V of the drive roller rotation.

[0114] 2) Calcul...

Embodiment 2

[0214] This embodiment discloses a method for ensuring the stiffness of a rectangular ring during rolling, which includes the following steps:

[0215] 1) The axial feed rate per revolution of 5m 2219 aluminum alloy ring rolling is determined.

[0216] Ring blank initial outer diameter D 0 =3600mm, initial inner diameter of ring blank d 0 =3140mm, ring blank initial wall thickness H 0 =230mm, ring blank initial height B 0 =500mm, core roll feed speed The shear yield strength of the 2219 aluminum alloy material corresponding to the rolling temperature is k=20.2Mpa, the friction coefficient between the ring and the roll μ=0.3, and the yield stress of the 2219 aluminum alloy material corresponding to the rolling temperature is σ s =35Mpa, the friction factor between the ring and the roller m=0.52, the top angle of the tapered roller γ=17.5°, the angle between the guide roller and the z-axis θ=45°, the radius of the tapered roller corresponding to the contact between the tape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com