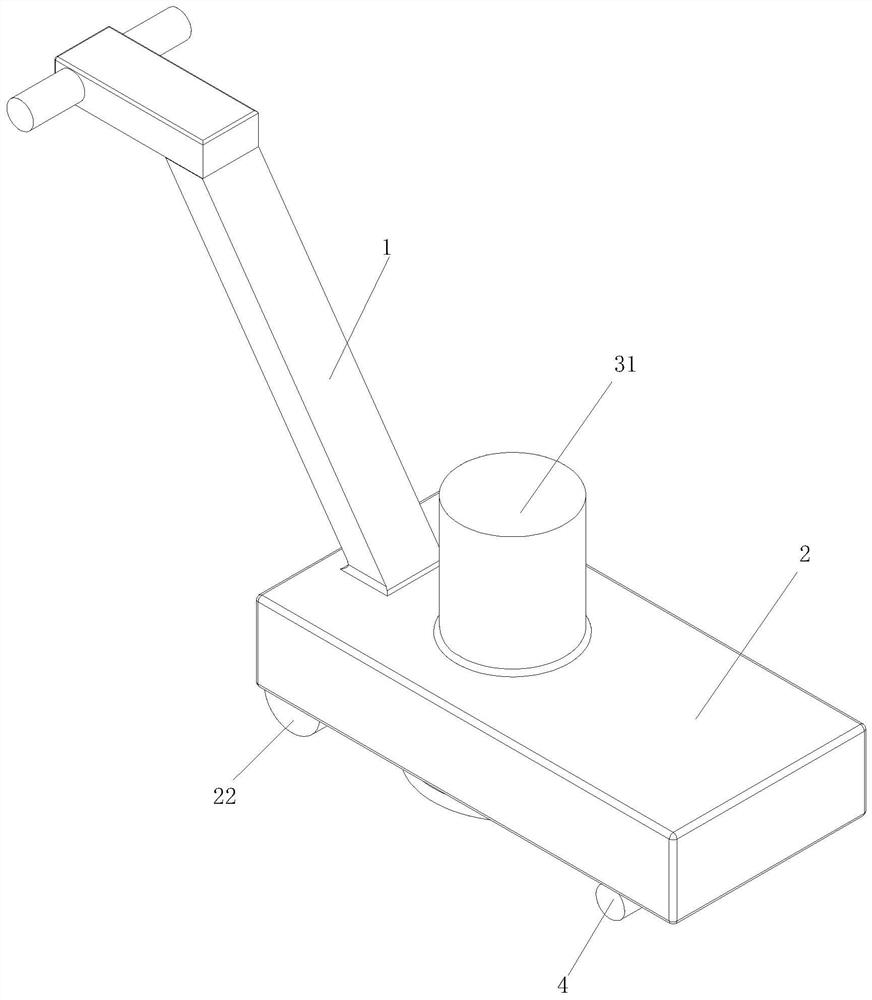

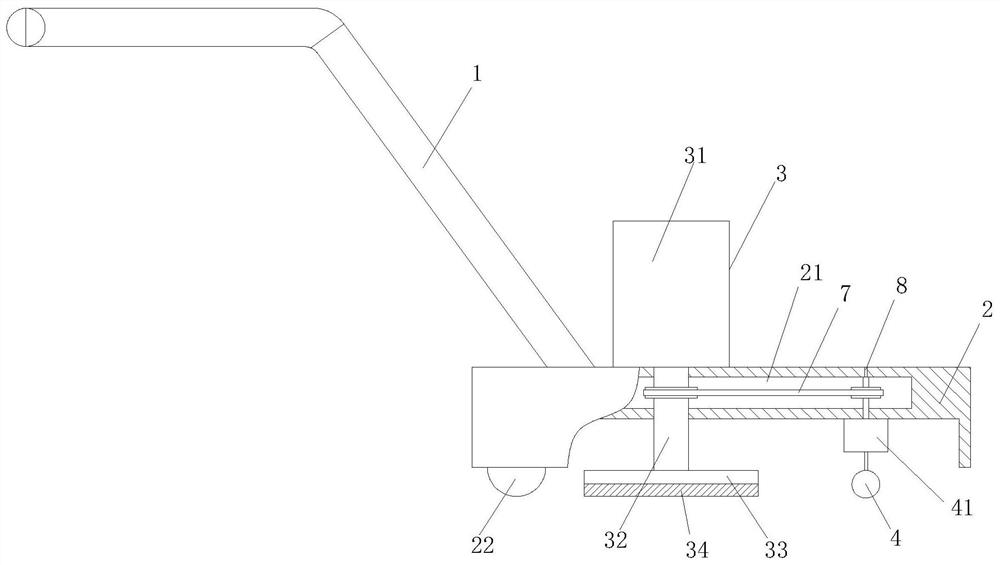

A kind of emery floor grinding device

A technology of emery and grinding, applied in the field of emery floor grinding devices, can solve the problems of affecting the working state of the grinding device, the separation of grinding discs, and the waste of working time of staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

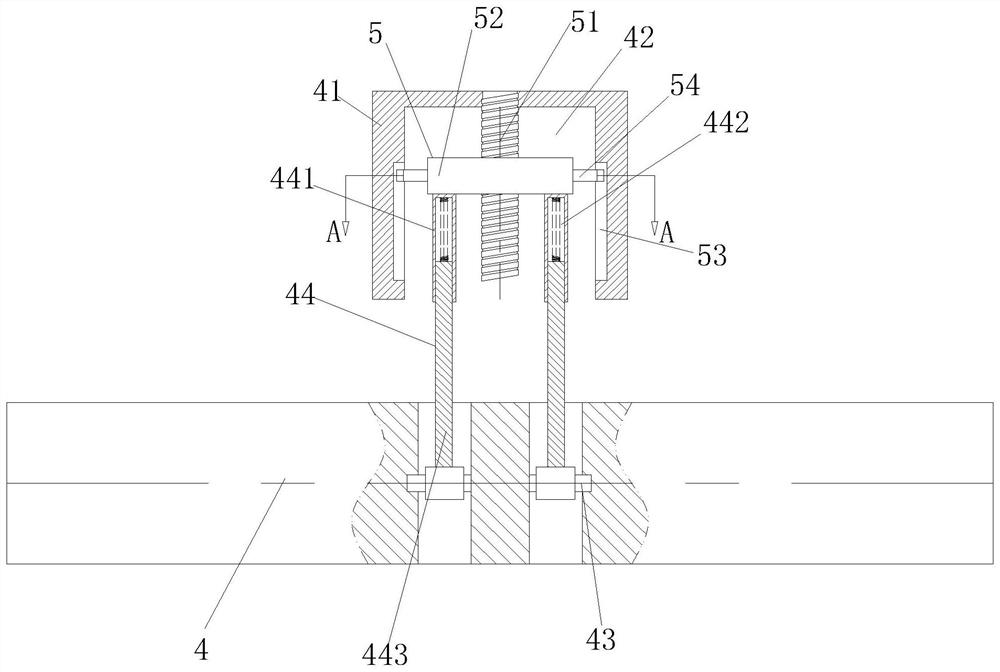

[0028] As an embodiment of the present invention, the first connecting post 44 includes a second connecting post 441 and a third connecting post 443; the second connecting post 441 is affixed to the bottom end of the adjustment member 5, and the second connecting post 441 The bottom end of the column 441 is provided with a guide groove 442; the top end of the third connecting column 443 is fixedly connected to the top of the guide groove 442 by a spring, and the third connecting column 443 is slidably connected in the guide groove 442, and the bottom end of the third connecting column 443 Rotationally connected on the second rotating shaft 43; the guide groove 442 and the third connecting column 443 are square; during work, when some sharp particles are encountered during the movement of the pinch wheel 4, because the pinch wheel 4 mainly plays a role The top of the shell 2 is sharply worn, so when the pressure roller 4 moves, it will lift the pressure roller 4, and when the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com