Unmanned aerial vehicle with spiral feeding and sowing mechanism

A technology of seeding mechanism and screw feeding, which is applied in the directions of seeder parts, hole seeding machine, seeding, etc., can solve the problems of uncontrollable planting depth, increased manual labor, and no automatic seeding, etc., and achieves increased automatic seeding function. , Increase the survival rate of germination, the effect of accurate planting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

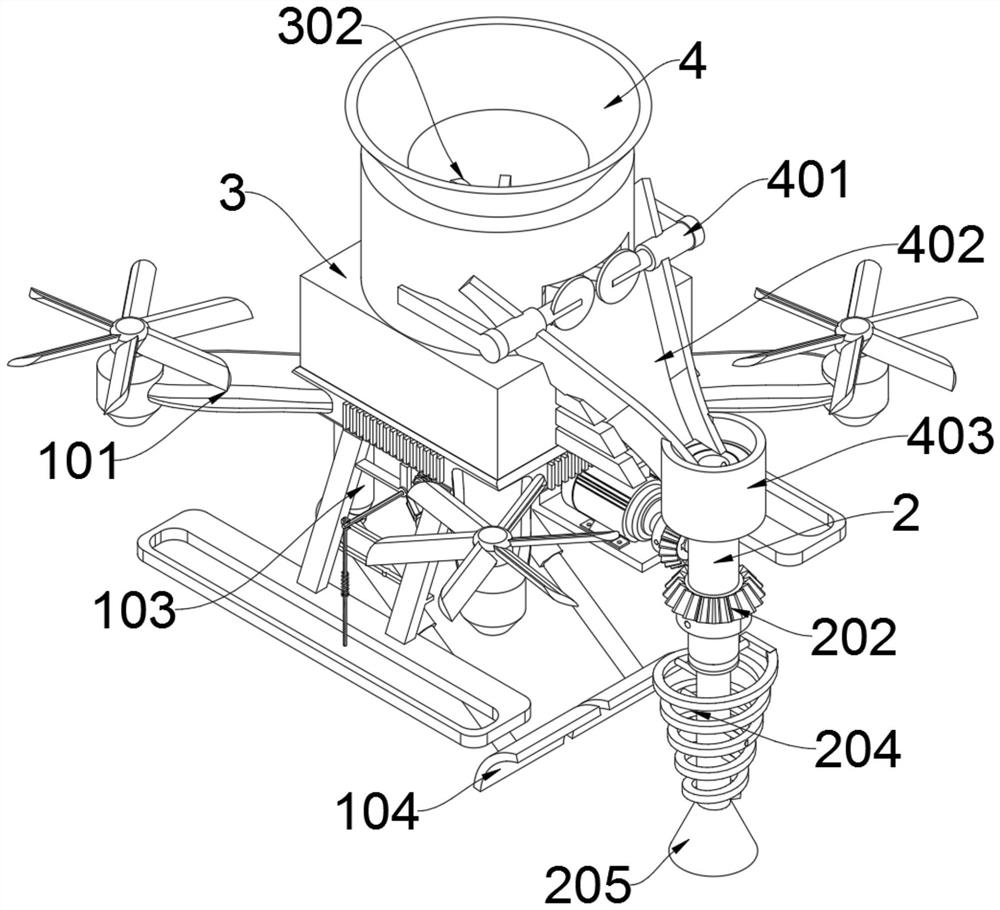

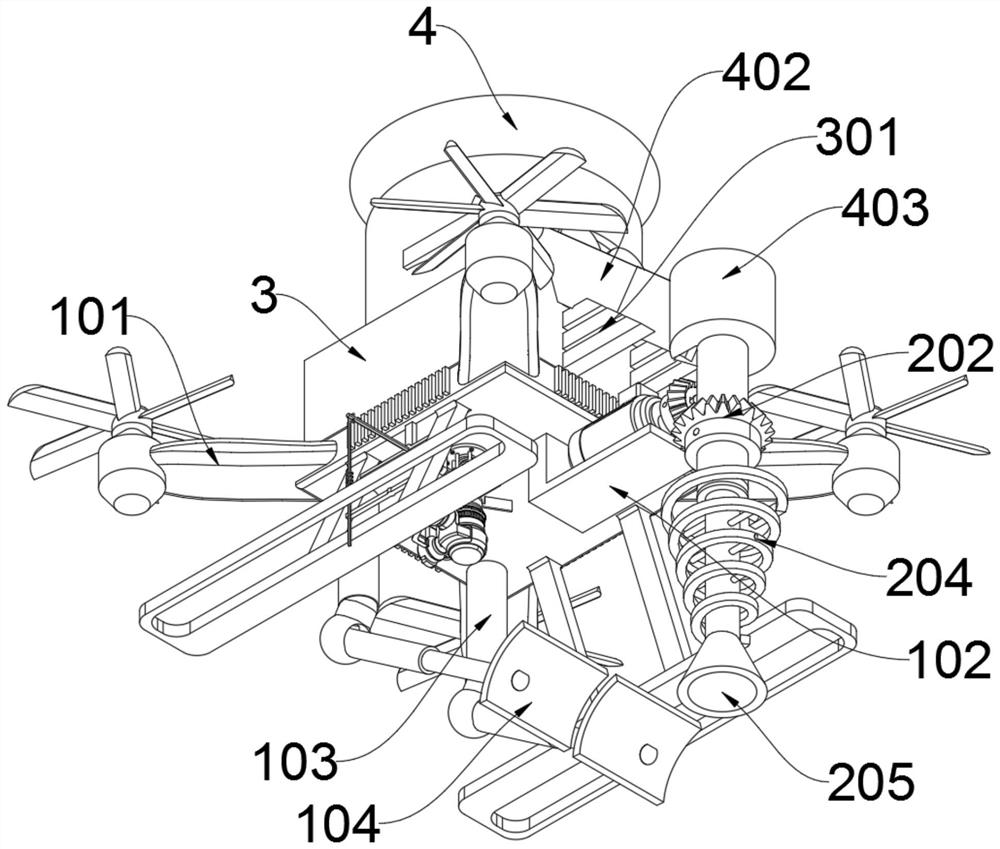

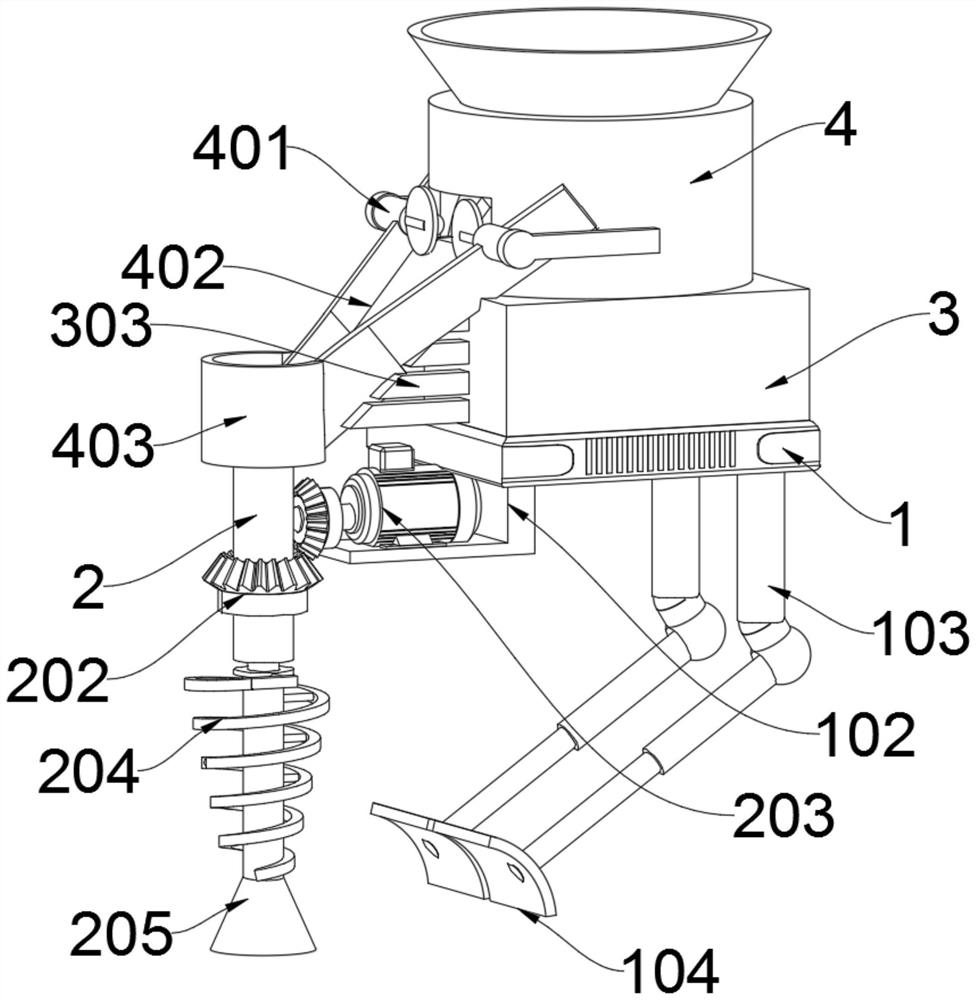

[0033] as attached figure 1 To attach Figure 7 Shown:

[0034] The invention provides an unmanned aerial vehicle with a spiral feeding and seeding mechanism, which includes a base 1; the base 1 is a cuboid structure, and a hollow cylindrical filter tube 2 is vertically fixed on the outer end of the base 1; the base 1 is centered on the upper end The inner cabinet 3 of hollow cuboid shape is connected and installed; the center upper end of inner cabinet 3 is connected and installed with a hollow storage box 4 made up of a cylinder and a cone; A set of wings 101 are respectively installed at the four corners on the outside of the base 1, and an L-shaped stand 102 is fixedly installed on the front side of the lower end of the base 1, and a pair of spherical and cylindrical bodies are respectively connected to the rear of the stand 102. Adjusting rod 103, the top of the front end of adjusting rod 103 is respectively connected and installed with a pair of push plates 104 made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com