Hollow glass filling and bonding equipment

A glass and equipment technology, applied in the field of insulating glass filling and bonding equipment, can solve the problems affecting the bonding effect of insulating glass, affecting the bonding efficiency of insulating glass, and glass shaking, so as to reduce the physical movement of personnel, reduce the glass breakage rate, and improve the The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

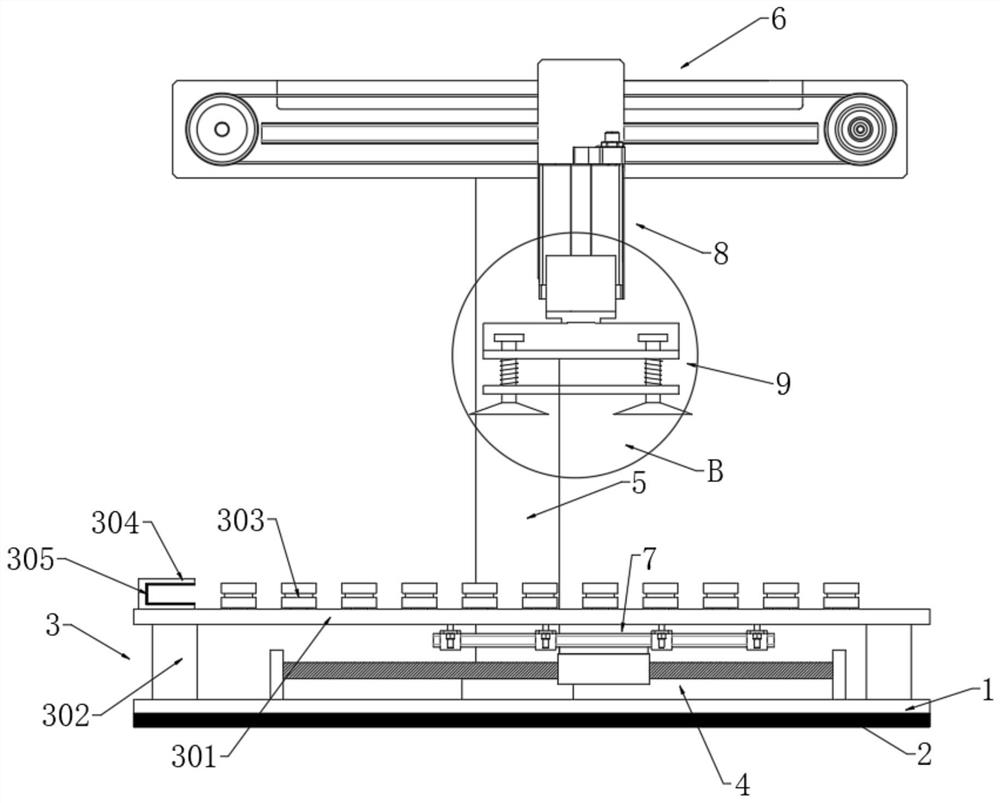

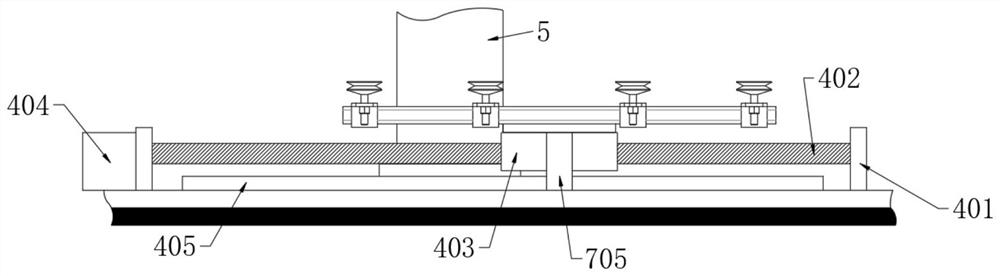

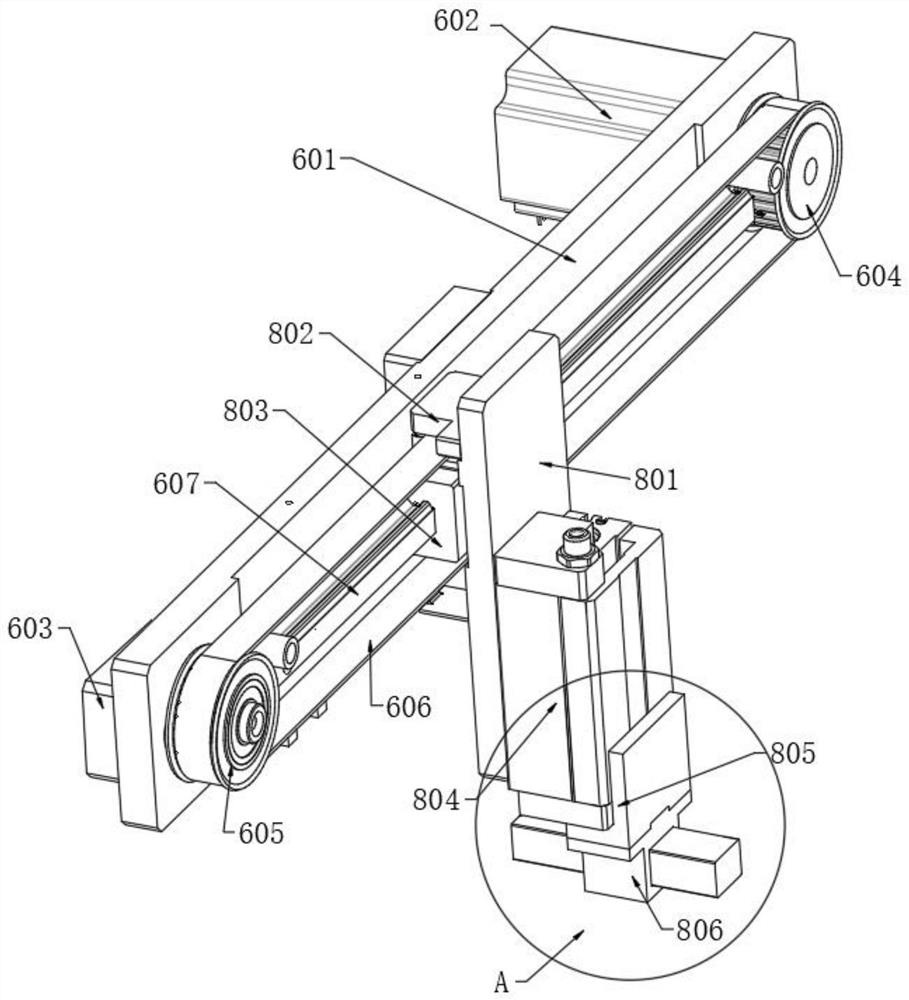

[0040] Please refer to the attached Figure 1-6 , a hollow glass filling bonding equipment, comprising:

[0041] Bottom plate 1, the lower surface of bottom plate 1 is provided with anti-skid pad 2;

[0042] Further, the set base plate 1 has a rectangular structure, which plays a role in supporting the device, and the anti-slip pad 2 arranged on the lower surface of the base plate 1 has the same area as the base plate 1, which improves the overall stability of the device.

[0043] The positioning assembly 3, the positioning assembly 3 includes a U-shaped positioning frame 301, the four corners of the lower surface of the U-shaped positioning frame 301 are vertically welded with support legs 302, and the support legs 302 are fixedly connected to the upper surface of the base plate 1;

[0044]Further, the set positioning assembly 3 accurately positions the first piece of glass;

[0045] The first moving part 4 is formed on the upper surface of the bottom plate 1;

[0046] Fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com