Telescopic rotary hydraulic walking pile machine

A telescopic, rotating, hydraulic technology, applied in drilling equipment, drilling equipment and methods, and earth-moving drilling and mining, etc., can solve problems such as inconvenient transportation and construction, cumbersome disassembly and assembly, and extended working cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

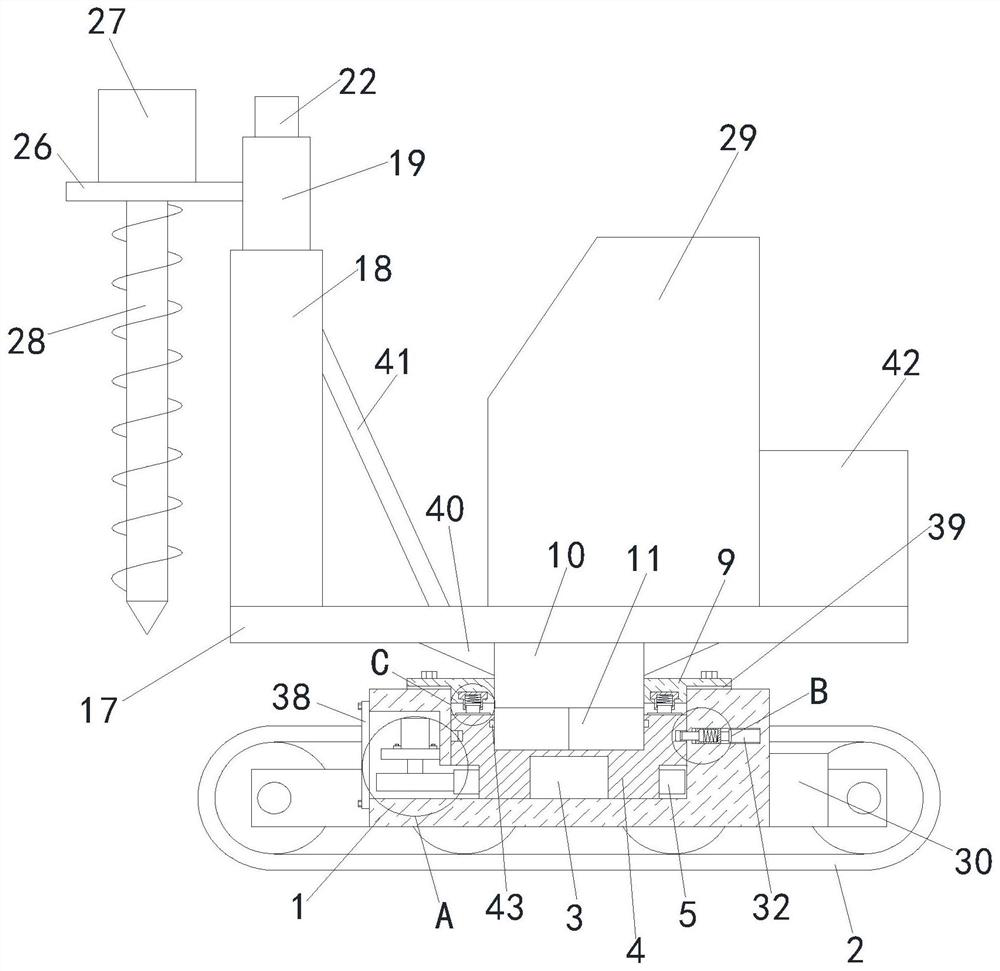

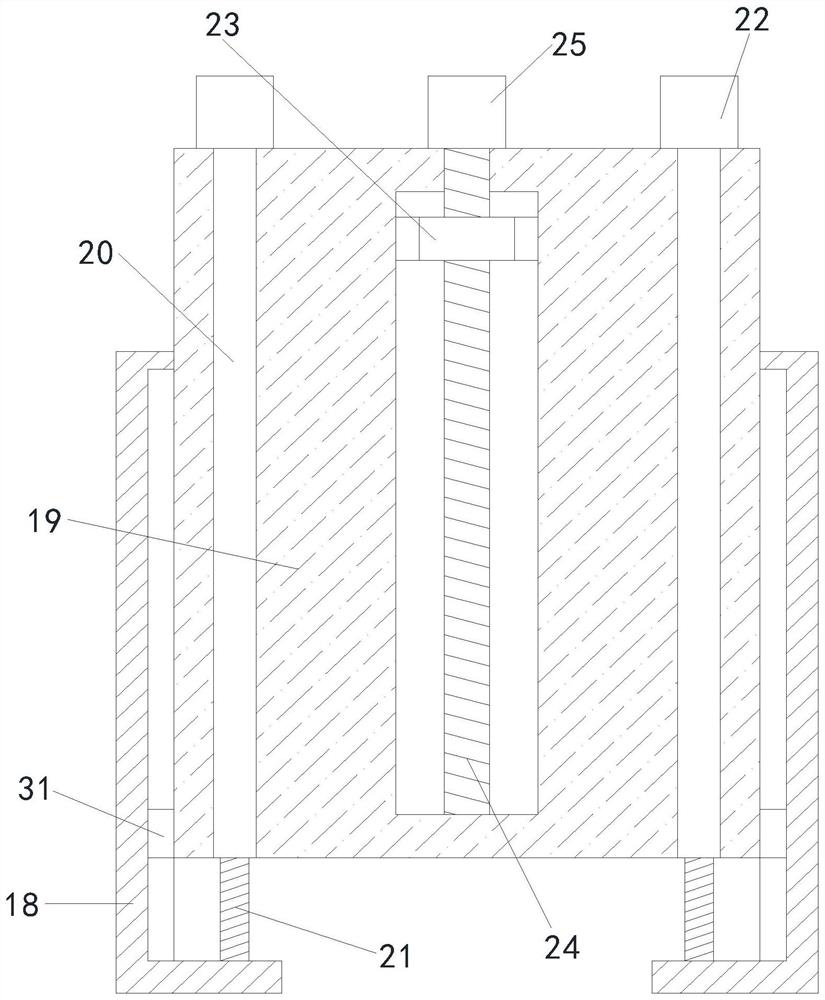

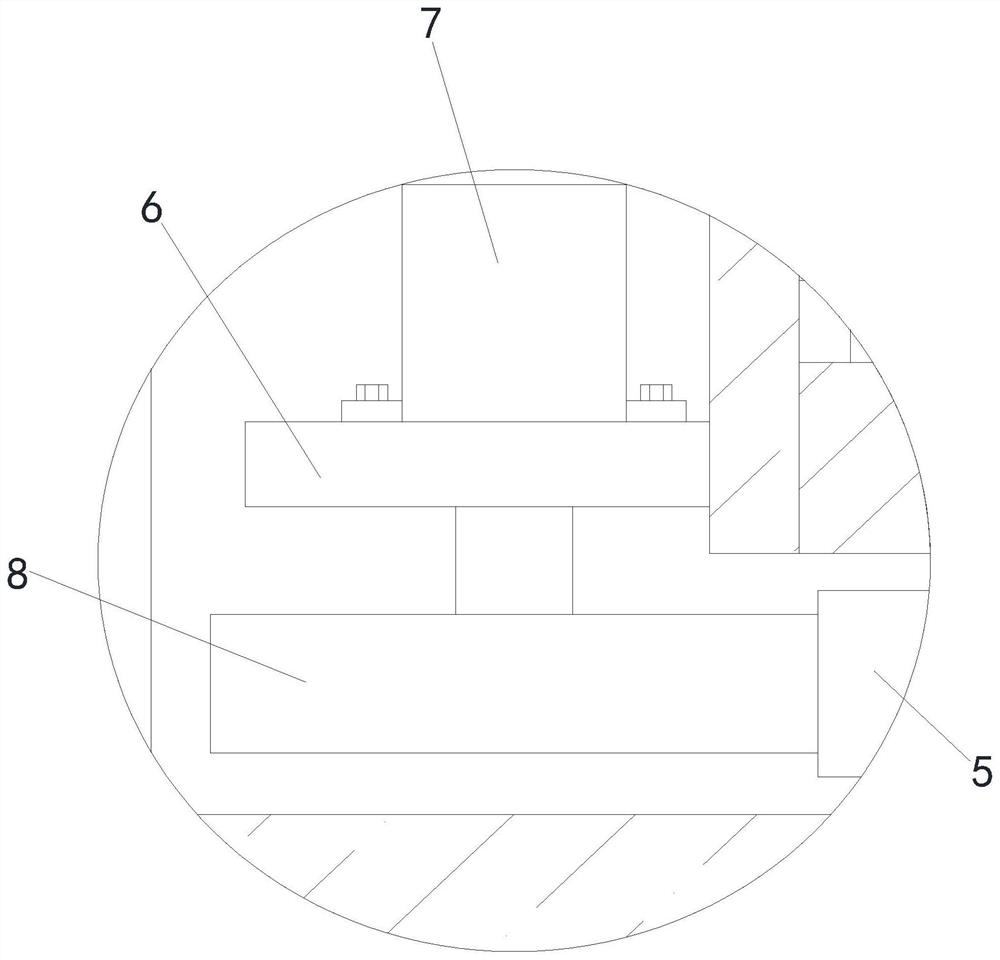

[0030] see Figure 1-6, a telescopic rotary hydraulic walking pile driver, comprising a base 1, crawler belts 2 are installed on the front and rear ends of the base 1, a first circular groove is arranged on the top of the base 1, and a fixed bottom end of the first circular groove is fixedly connected with a fixed The column 3 is connected with the rotating column 4 inside the round groove, the inside of the rotating column 4 and the base 1 is provided with a clamping mechanism, the bottom of the rotating column 4 is provided with a second circular groove, and the second circular groove is connected with the fixed column 3 , the bottom of the outer side of the rotating column 4 is provided with a gear ring 5, the left end of the base 1 is provided with a groove, the bottom side of the right end of the groove is provided with a through groove connected to the inside of the first circular groove, and the inside of the groove is fixed A mounting plate 6 is connected, and a rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com