Load reduction method for wind driven generator

A wind power generator and load reduction technology, which is applied to wind power generators, control of wind power generators, wind power generation, etc., can solve problems such as increased production costs, exceeding design loads, and accidents, so as to speed up feathering speed and avoid large loads , Inhibit the effect of speeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

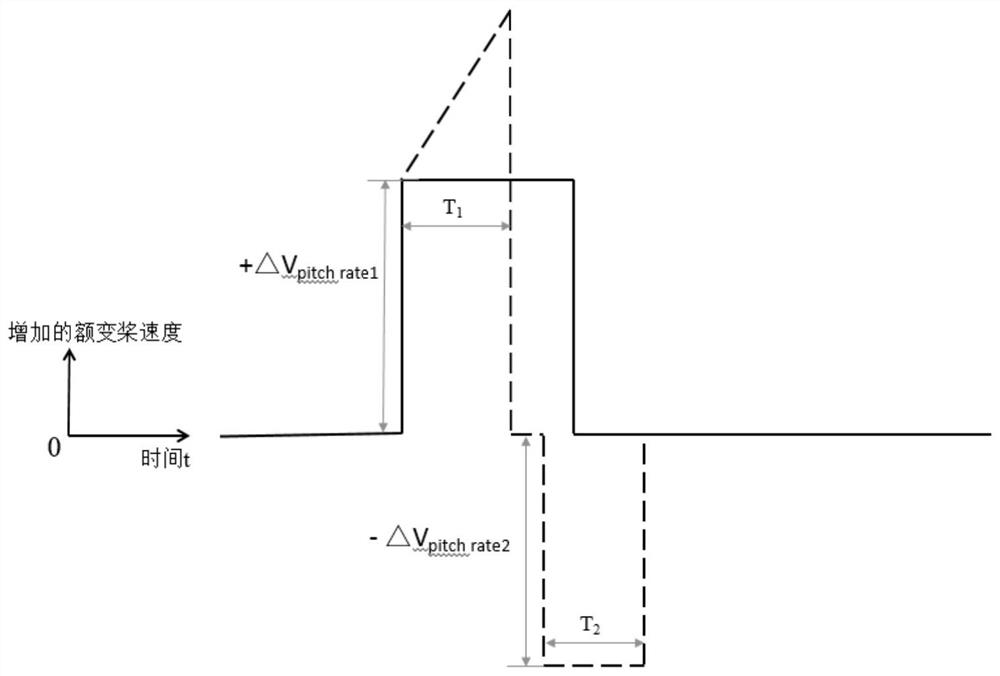

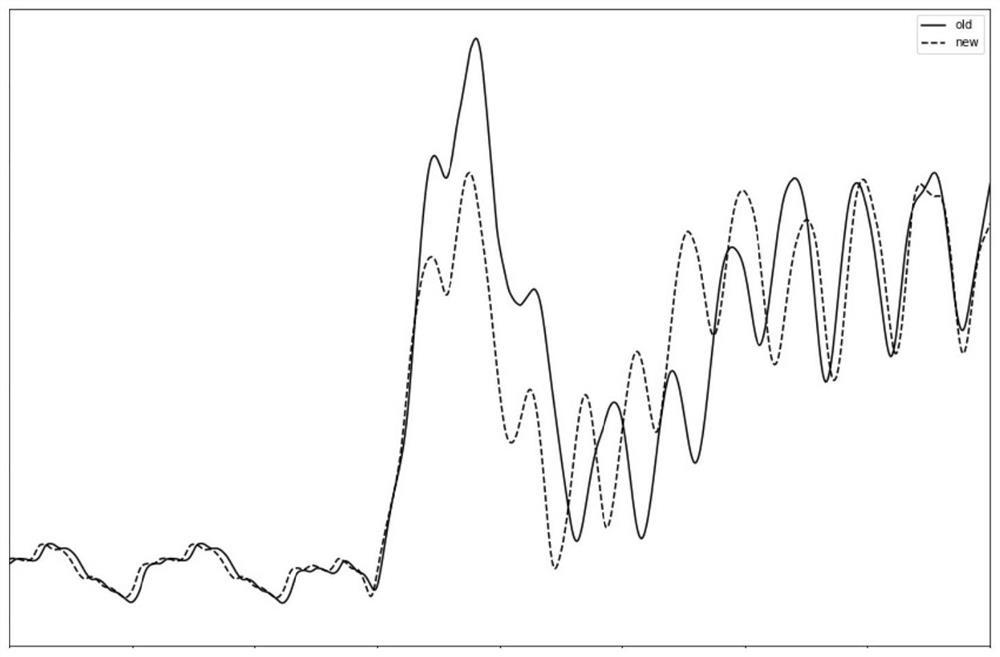

[0023] based on the following figure 2 and image 3 , specifically explain the preferred embodiment of the present invention.

[0024] The present invention provides a wind power generator load reduction method, which monitors the first speed factor and the second speed factor in real time, and when the first speed factor exceeds a threshold and the second speed factor is greater than 0, an additional positive variable is added to the wind power generator. Propeller speed, after adding a positive additional pitch speed to the wind generator, when the second speed factor becomes less than 0, then add a negative additional pitch speed to the wind generator.

[0025] The first speed factor S1=V gen ×V gen ’, where V gen is the wind turbine speed, V gen ’ is the derivative of the wind turbine speed.

[0026] The second speed factor S2=(V gen ×V gen ’)’, where V gen is the wind turbine speed, V gen ’ is the derivative of wind turbine speed (ie, angular acceleration). Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com