rice transplanter

A technology for a rice transplanter and an actuator, which is applied in the field of rice transplanters, can solve the problems of inability to realize automation, prone to failure, complex structure, etc., and achieves the effect of improving workability and accuracy, reducing failures and misoperations, and realizing light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

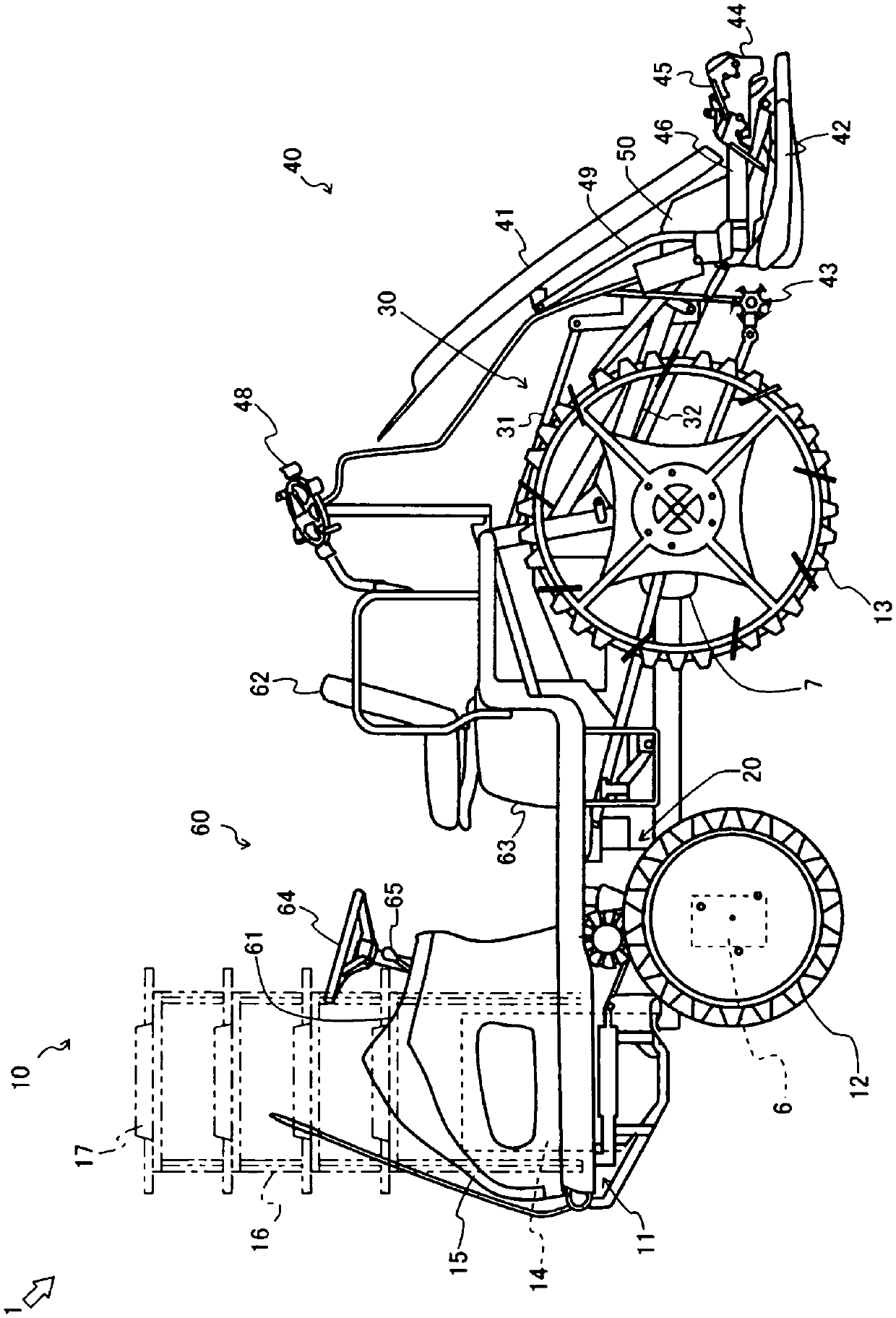

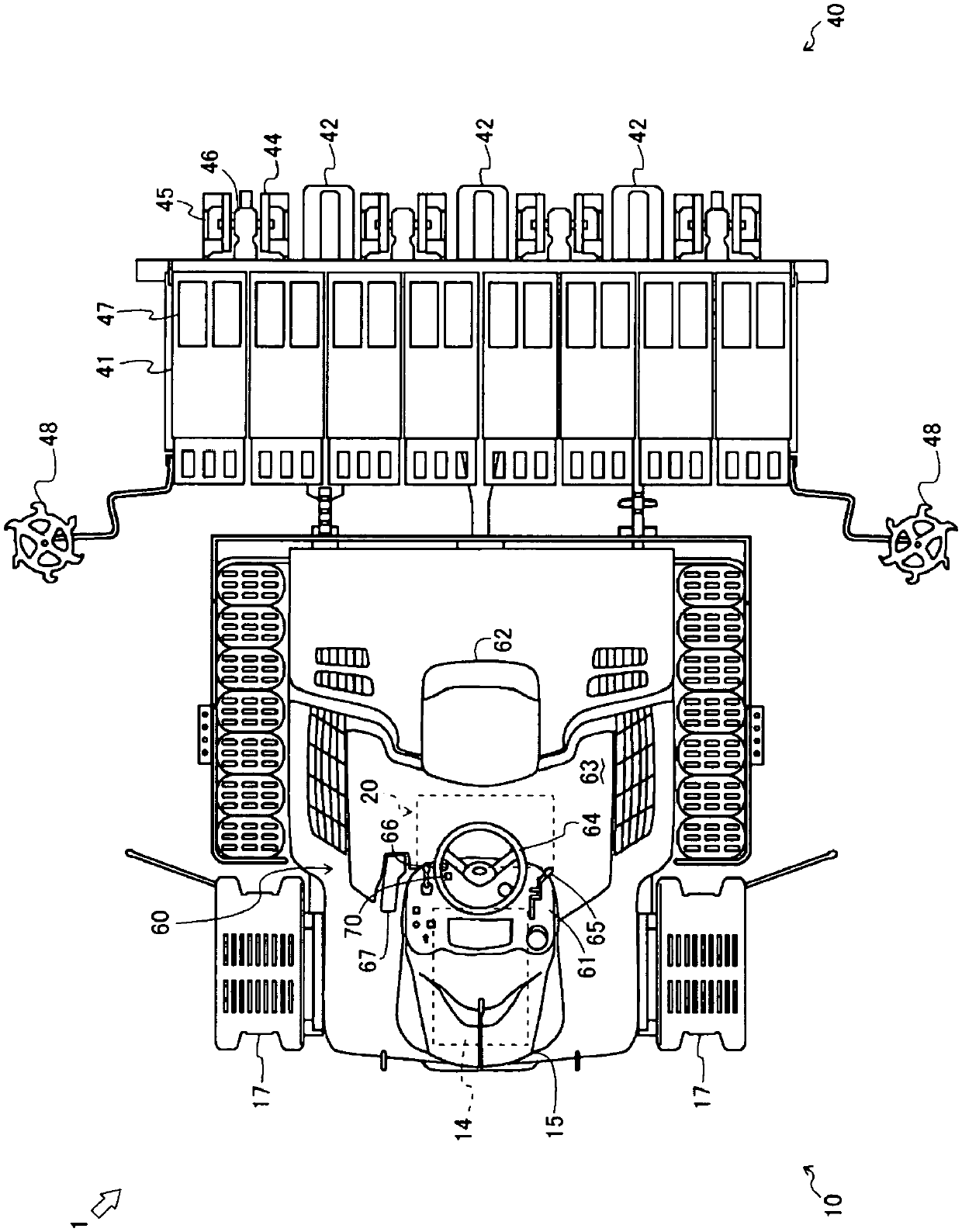

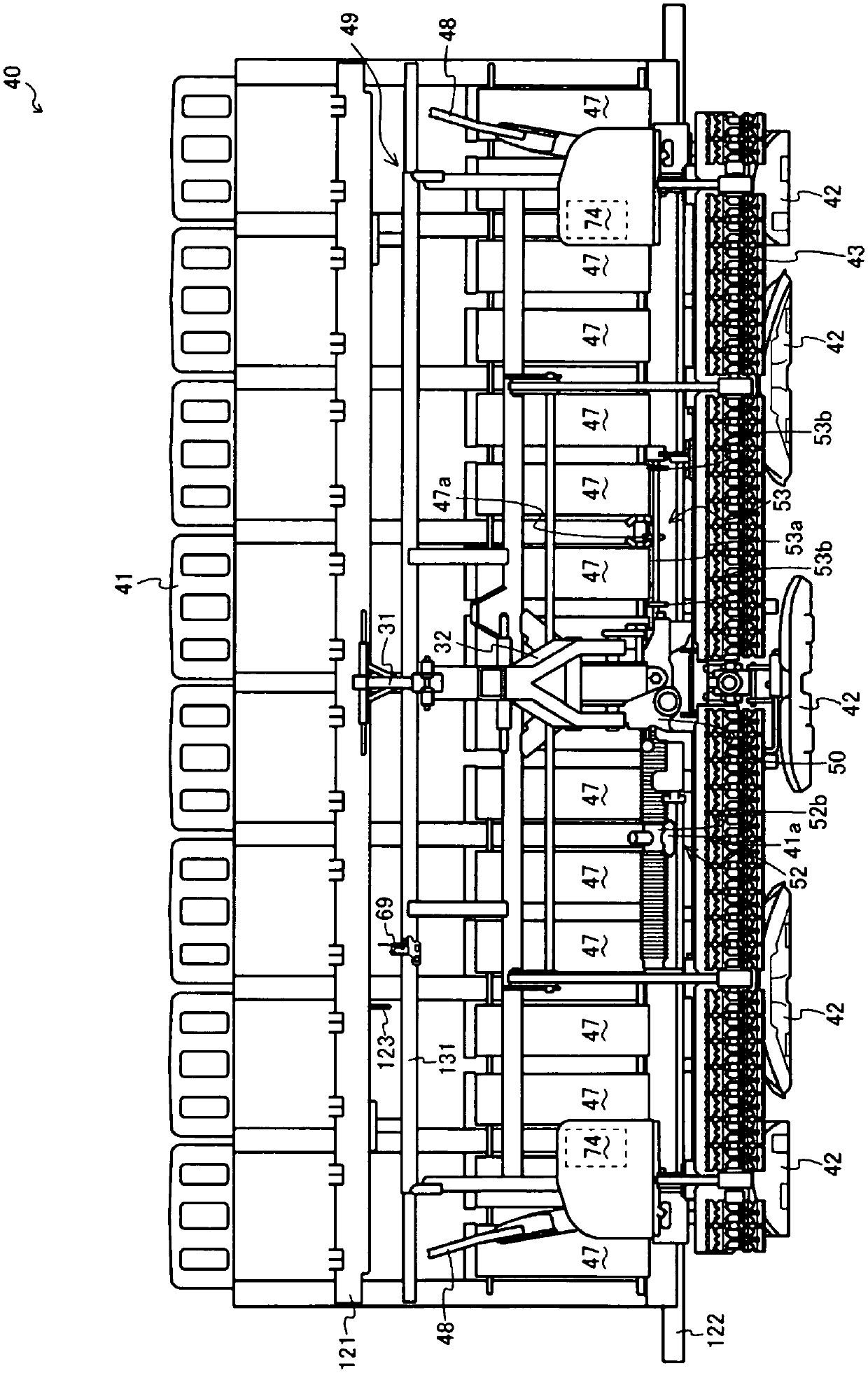

[0070] First, the overall structure of the rice transplanter 1 which concerns on 1st Embodiment of this invention is demonstrated. In addition, in this embodiment, although the rice transplanter is the rice transplanter of 8 planting lines, it is not limited to this, For example, the rice transplanter of 6 planting lines or 10 planting lines may be sufficient.

[0071] Such as figure 1 and figure 2 As shown, the rice transplanter 1 has a traveling body 10 and a planting unit 40 , and can plant seedlings in the farmland through the planting unit 40 while traveling on the traveling body 10 . The planting unit 40 is arranged at the rear of the traveling body 10 , and is connected to the rear of the traveling body 10 so as to be able to move up and down via the elevating mechanism 30 .

[0072] The lift mechanism 30 is provided between the traveling vehicle body 10 and the planting unit 40 . Specifically, the top ring 31 and the bottom 32 are spanned between the vehicle body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com