A rolling bearing fault diagnosis method and system

A rolling bearing and fault diagnosis technology, which is applied in the testing of machine/structural components, the testing of mechanical components, instruments, etc., can solve the problem of less adaptive selection method of penalty factor α, so as to overcome the uncertainty of accuracy and improve the accuracy. , to avoid the effect of aliasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

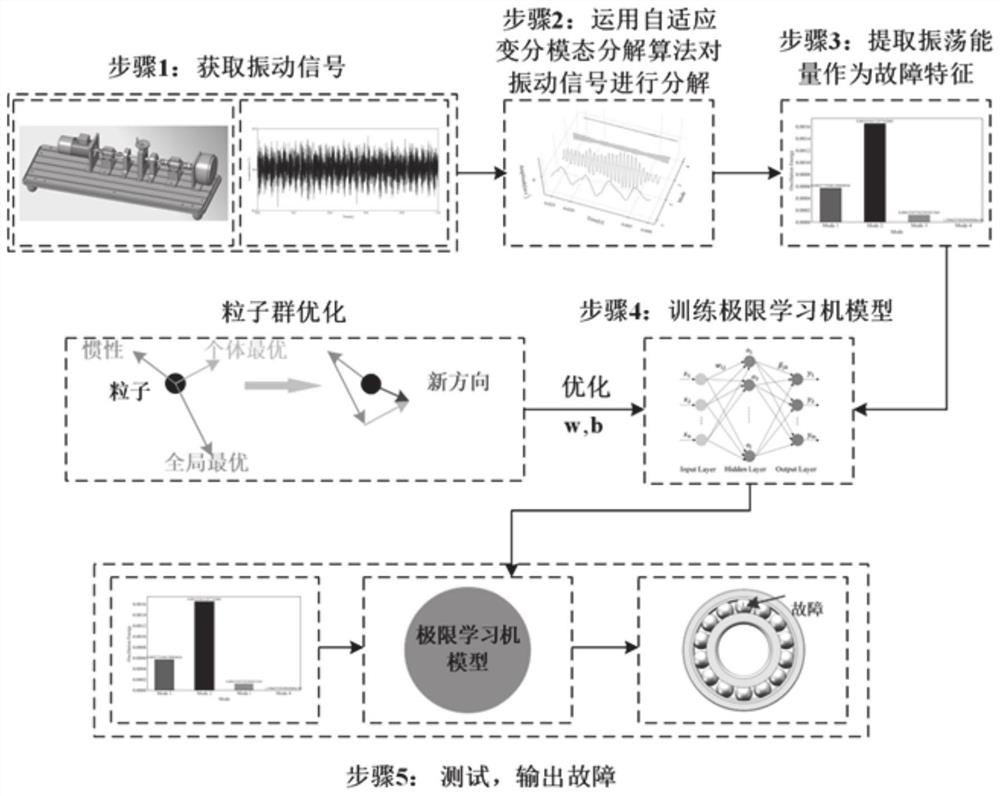

[0033] The present disclosure provides a rolling bearing fault diagnosis method, including:

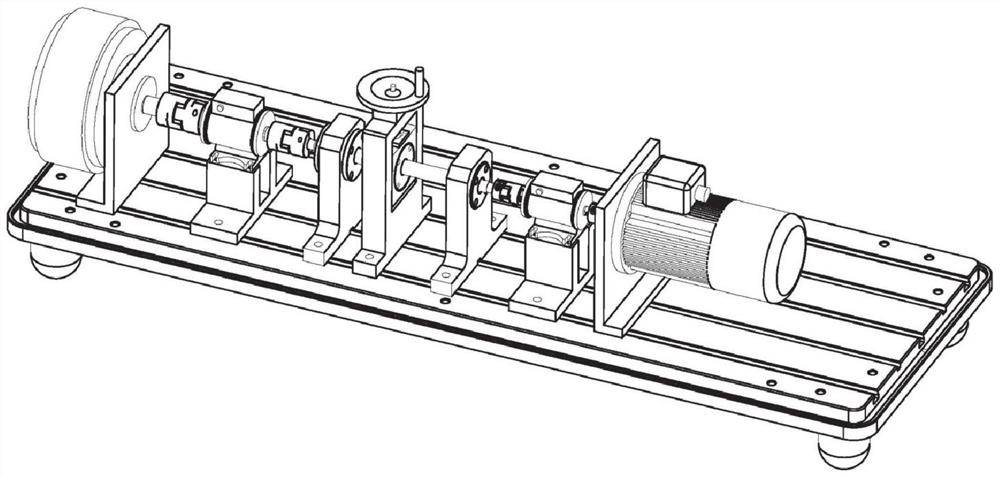

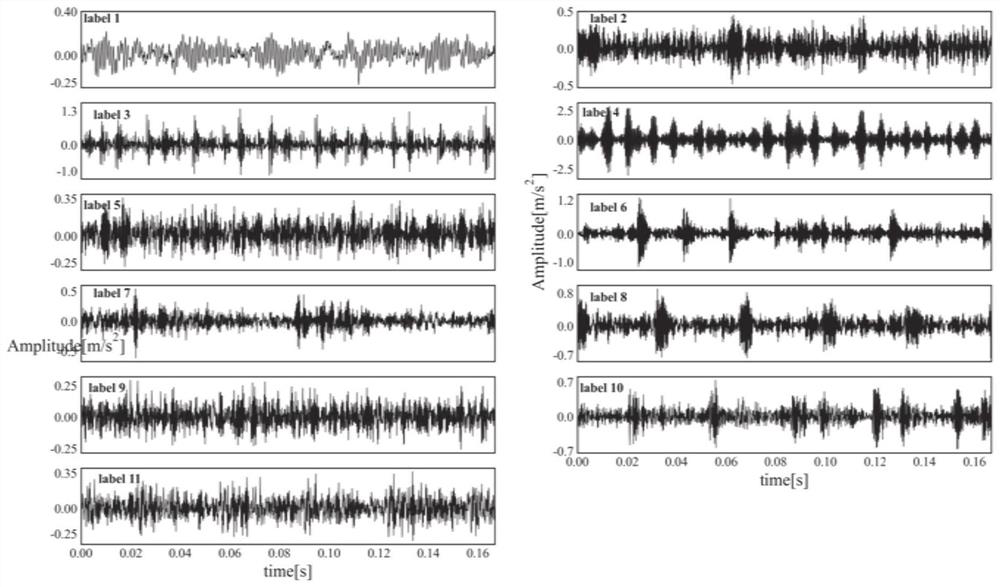

[0034] Collect the vibration signal of the rolling bearing to be detected, and randomly divide the training set and the test set;

[0035] Input the vibration signal of the rolling bearing into the fault diagnosis model to obtain the fault diagnosis result;

[0036] The fault diagnosis model is obtained by forming a training set and a test set based on time-domain vibration signals of different fault types of rolling bearings for training and testing. The step of establishing the fault diagnosis model includes adaptively adapting the time-domain vibration signals of each fault type in the training set. The variational modal decomposition obtains the corresponding modal components, obtains the fault characteristics of each modal component, and uses the fault characteristics as the input of the classifier model; the penalty factor of the adaptive variational modal decomposition is deter...

Embodiment 2

[0059] The present disclosure provides a rolling bearing fault diagnosis system, including:

[0060] The data acquisition module is configured to: collect the vibration signal of the rolling bearing to be detected;

[0061] The fault diagnosis module is configured to: input the vibration signal of the rolling bearing into the fault diagnosis model to obtain the fault diagnosis result;

[0062] The fault diagnosis model is obtained by forming a training set and a test set based on time-domain vibration signals of different fault types of rolling bearings for training and testing. The step of establishing the fault diagnosis model includes adaptively adapting the time-domain vibration signals of each fault type in the training set. The variational modal decomposition obtains the corresponding modal components, obtains the fault characteristics of each modal component, and uses the fault characteristics as the input of the classifier model; the penalty factor of the adaptive vari...

Embodiment 3

[0065] A computer-readable storage medium is used for storing computer instructions. When the computer instructions are executed by a processor, the method for diagnosing rolling bearing faults as described in the above-mentioned embodiments is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com