Automatic Detection Method of Microwave Oven Timer

A detection method and timer technology, applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve problems such as failure of microwave ovens, inability to achieve complete inspection and calibration, and manual missed inspections, so as to improve detection accuracy, accuracy and The effect of reliable detection and accurate batch detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

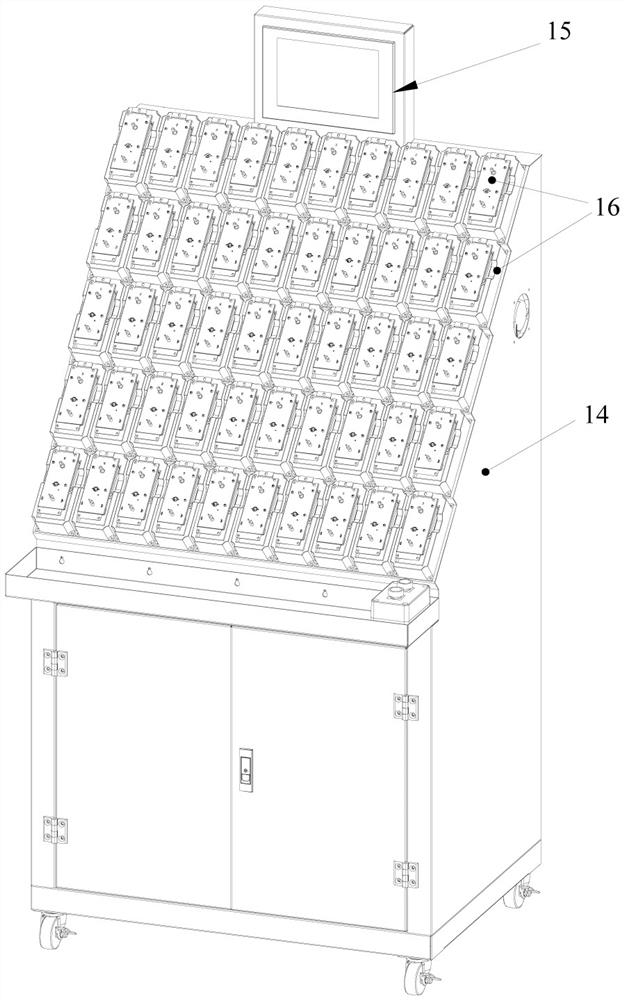

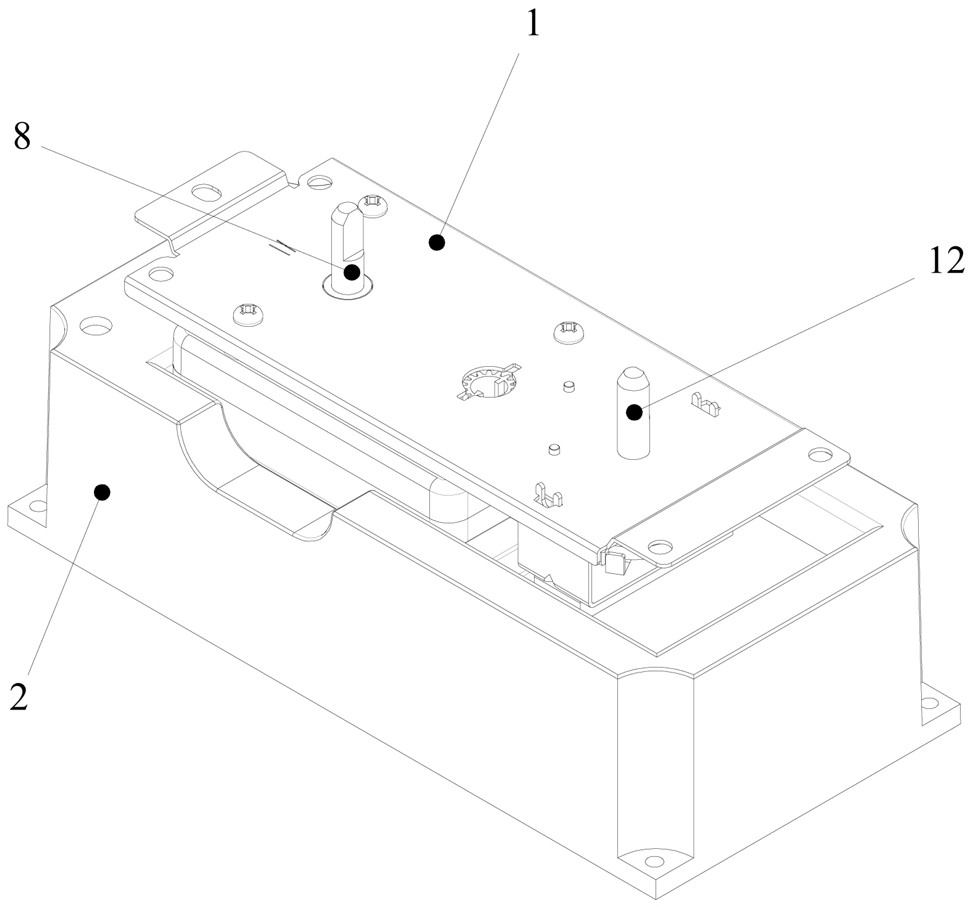

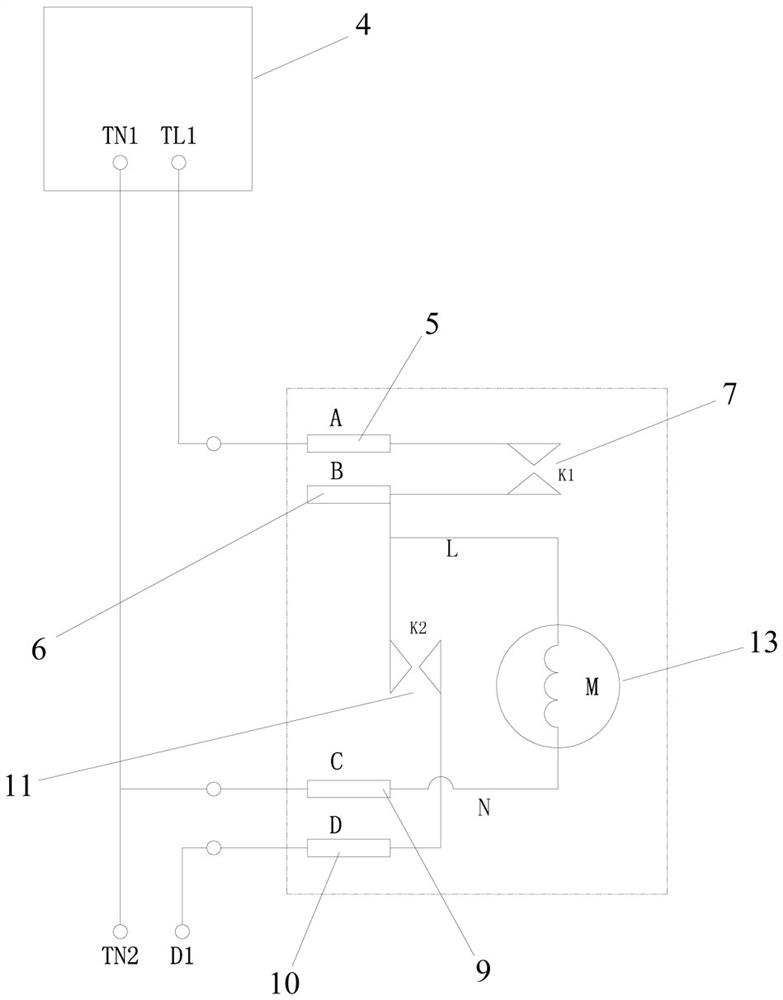

[0049] Such as Figure 1 to Figure 6 Shown, the microwave oven timer automatic detection equipment of the present invention comprises:

[0050] Several timer detection sub-modules 16 are used to fix the microwave oven timer 1 and be electrically connected with the microwave oven timer 1, and output detection signals;

[0051] The control electric cabinet 14 is used to provide the timer detection submodule 16 power supply, receive the detection signal output by the timer detection submodule 16, time the on-off time of the detection signal, and realize the power distribution function and timing of the microwave oven timer 1 function testing;

[0052] And a display using a touch screen 15 for displaying detection data and detection status, as well as detectable manipulation, the touch screen 15 is connected to the control electric cabinet 14;

[0053] Wherein, the controller in the control electric cabinet 14 adopts a PLC controller, each timer detection sub-module 16 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com