High-precision micro-displacement actuator for astronomical telescope mirror surface position adjustment

An astronomical telescope, high-precision technology, applied in instruments, installation, optics, etc., can solve the problems of limited travel magnification, immature technology and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

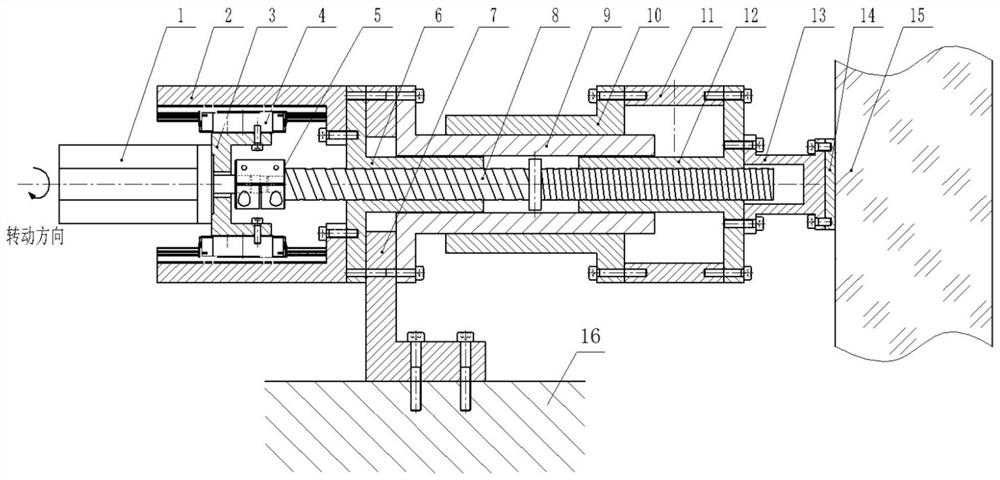

[0023] Such as figure 1 As shown, in this embodiment, a high-precision micro-displacement actuator for adjusting the mirror position of an astronomical telescope includes a double-thread screw 8, and the double-thread screw 8 includes two thread segments with the same helical direction and different leads. That is, the first thread segment (lead P1) and the second thread segment (lead P2), use the relative lead difference between the first thread segment and the second thread segment to realize the displacement output. The outer fitting sleeve of the first threaded section is provided with the first screw nut 6 that is fixedly connected on the telescope frame 16, the first threaded section is connected with a driving device that can drive the rotation of the double threaded screw mandrel 8, and the outer fitting sleeve of the second threaded section A second screw nut 12 is provided, and the second screw nut 12 is connected with the mirror surface 15 . This high-precision mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com