Roller fastening arrangement

A fastening and roller technology, applied in the field of roller fastening devices, can solve the problems of no longer being able to disassemble, difficult disassembling of the contact disc, disassembling of bolts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

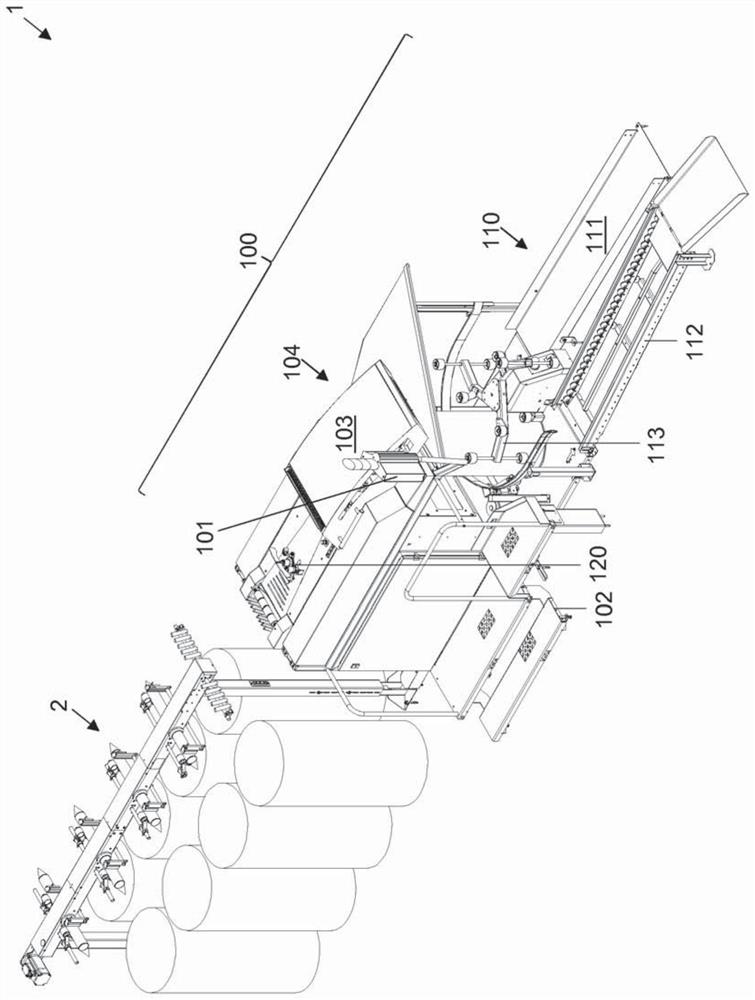

[0024] figure 1 An arrangement 1 with a creel 2 and a downstream draw frame 100 is shown in a typical arrangement.

[0025] The creel 2 is constructed in a known manner and will not be described again.

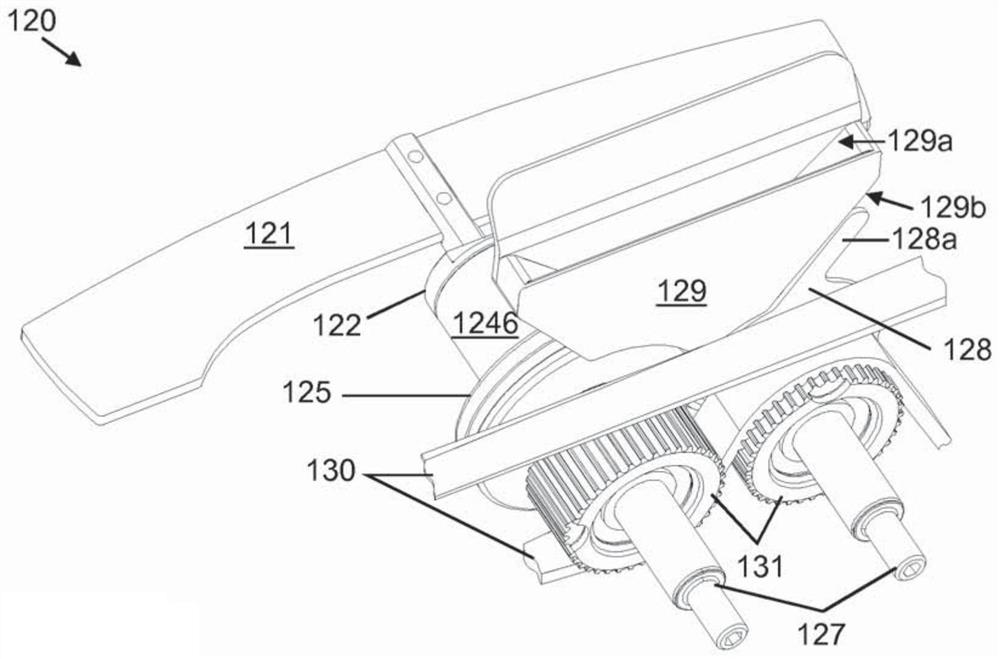

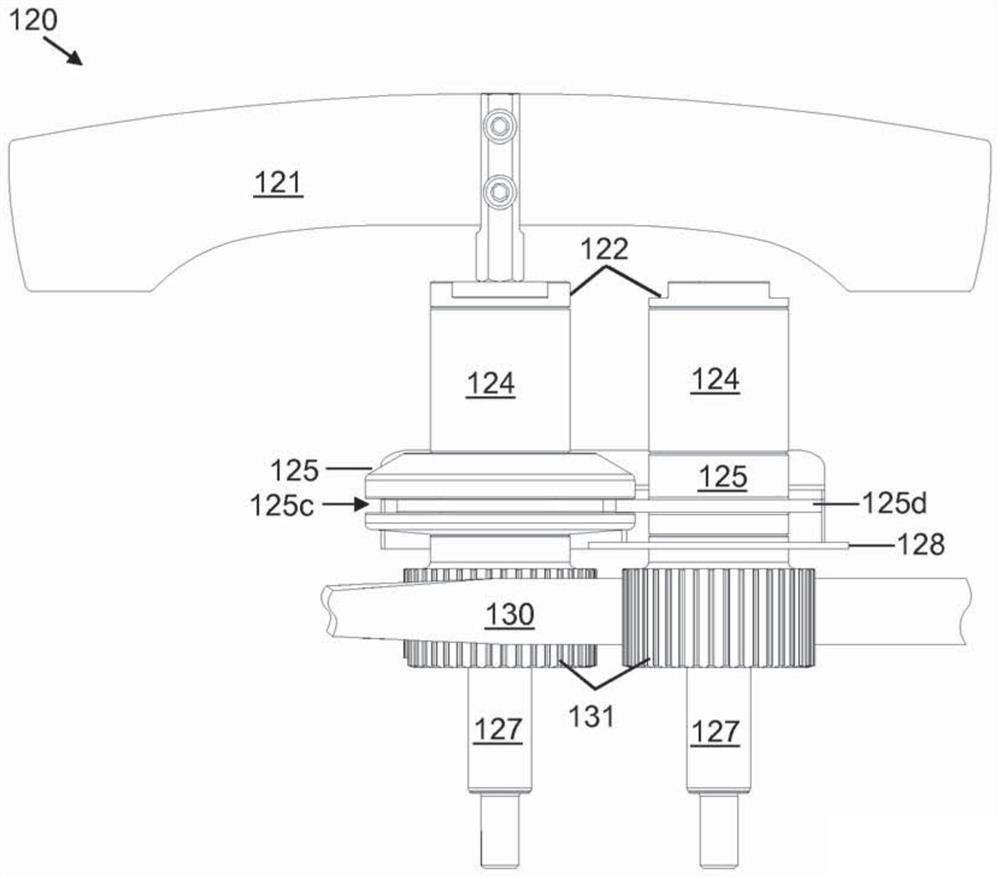

[0026] Furthermore, the draw frame 100 has a coiling device 110 on the delivery side. In the example shown, the coiling device 110 comprises a can rail 111 for full cans and a preferably driven can guide 112 which moves the empty cans to the actual, unmarked coil on the can changer of the bar device 110. The can changer has, for example, a can mover 113 in a known manner. On the side of the draw frame 100 there is an operating platform 102 . An operator terminal 101 is located here at one end of an operator platform 102 . Furthermore, a drafting mechanism cover 103 can be seen, which covers the drafting section 104 in a known manner. Upstream of the drafting section 104 in the direction of transport of the fiber sliver, there is a measuring system 120 with two unmarked m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com